Rotary reeling and unreeling mechanism of round cutter die cutting machine

A technology of retracting and unwinding materials and circular knife molds, which is applied in thin material processing, metal processing, and winding strips, etc., which can solve the problems of long alignment time, large space occupation, and increased adjustment time of retracting and unwinding materials, and achieve fixed Good limit effect, convenient installation and adjustment, and good guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

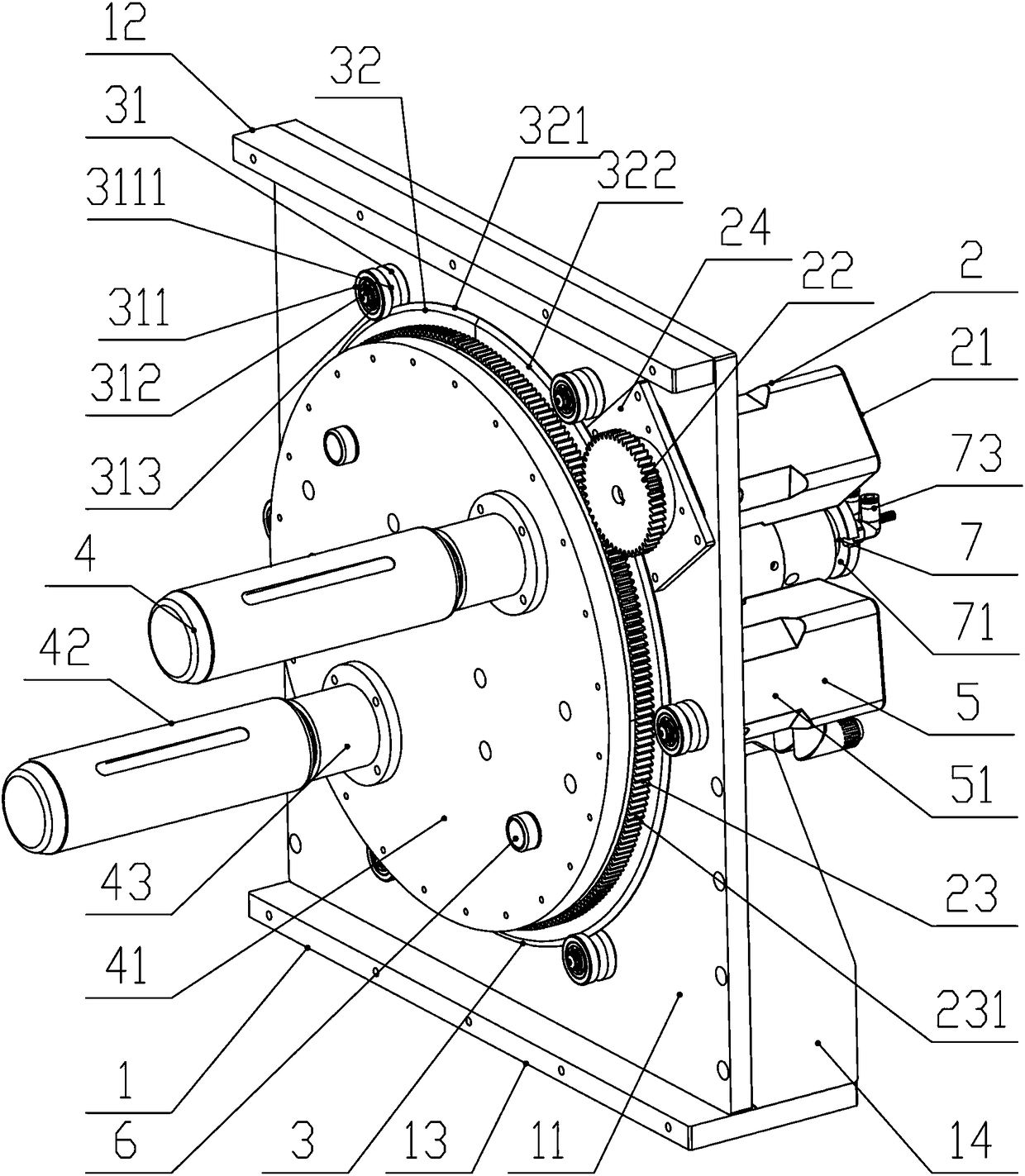

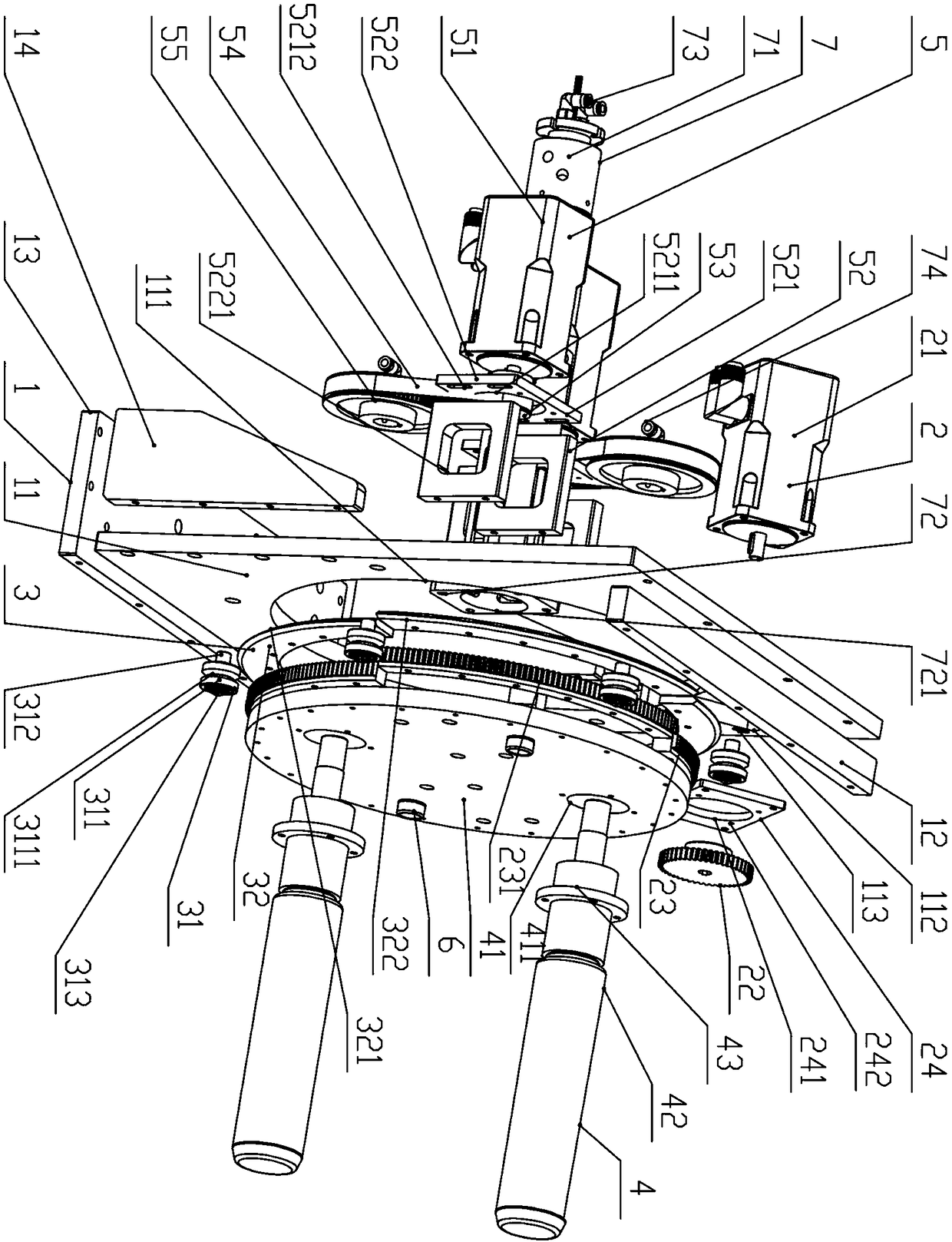

[0039] Figure 1 to Figure 9 A rotary feeding and unwinding mechanism of a circular knife die cutting machine according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a support beam assembly 1, a first drive part 2, a guide assembly 3, a retractable assembly 4 and a second drive part 5,

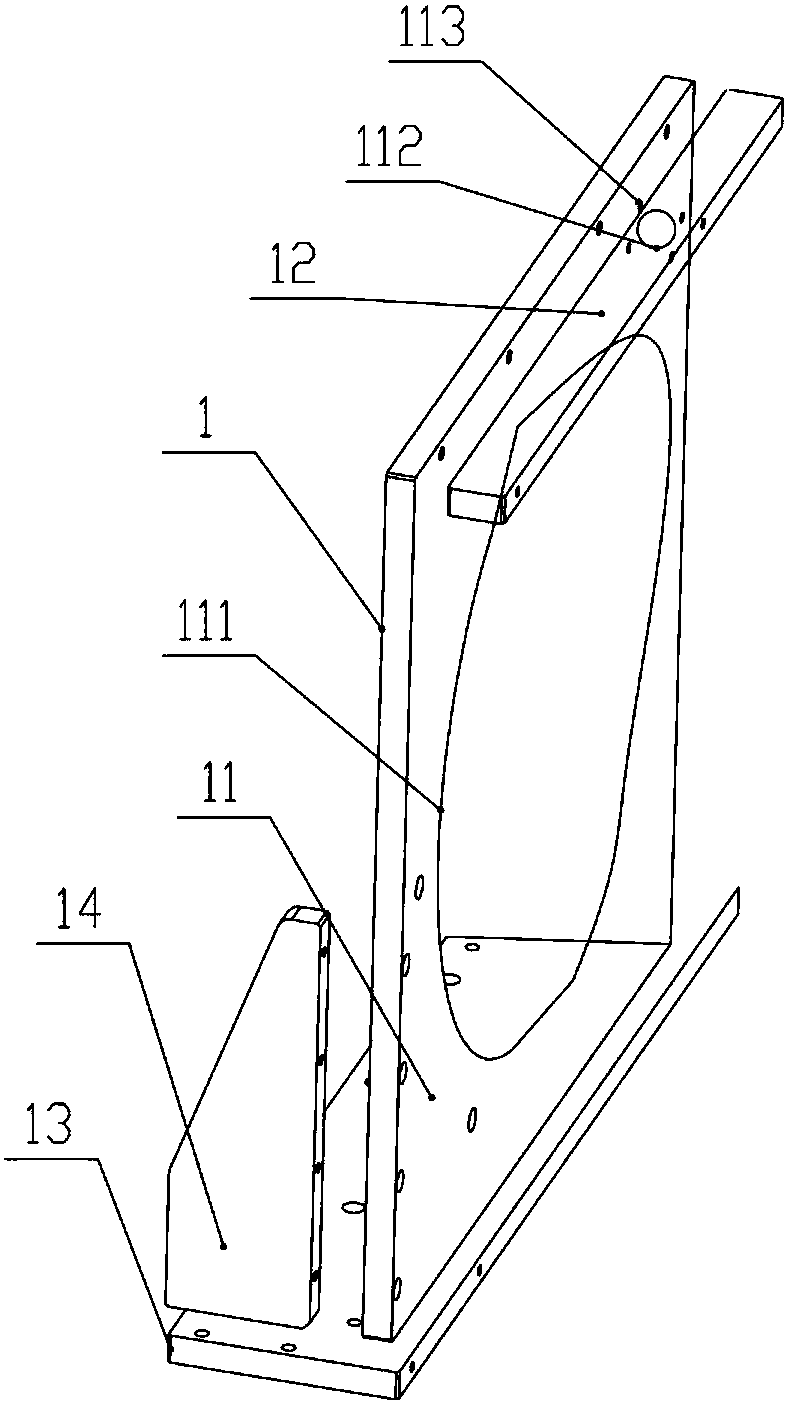

[0040] The support beam assembly 1 is fixed on the circular knife machine. The support beam assembly 1 includes a main wall panel 11 set up vertically. The center of the main wall panel 11 is provided with a first throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com