Multifunctional logistics tray, adjustment tool and adjustment method

A multi-functional and logistics technology, applied in the direction of transportation and packaging, rigid containers, containers, etc., can solve problems such as troublesome and inability to use forklifts, and achieve the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

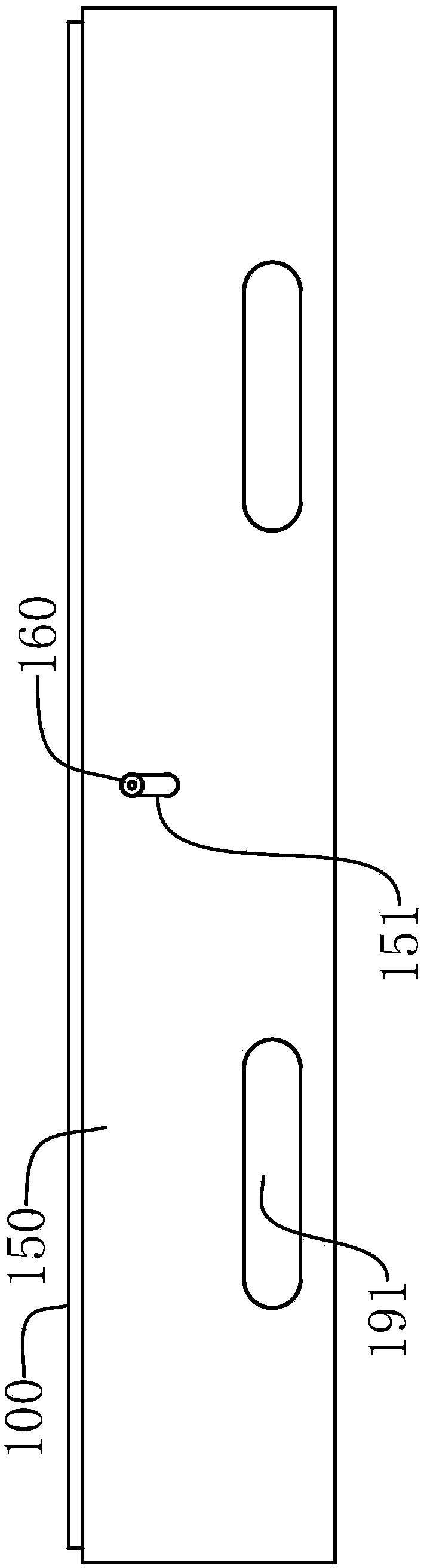

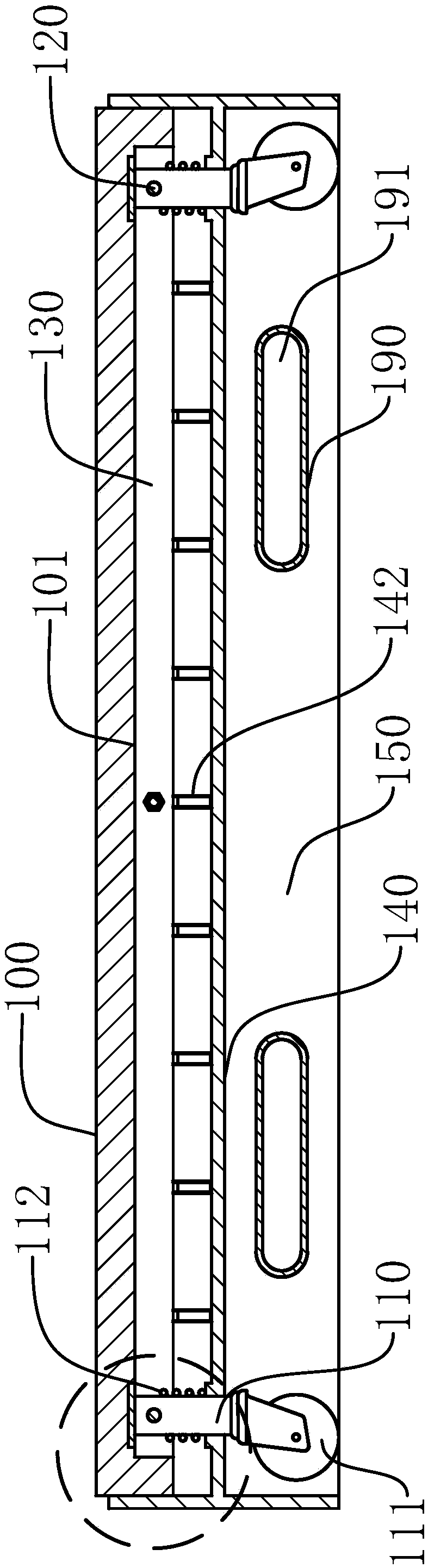

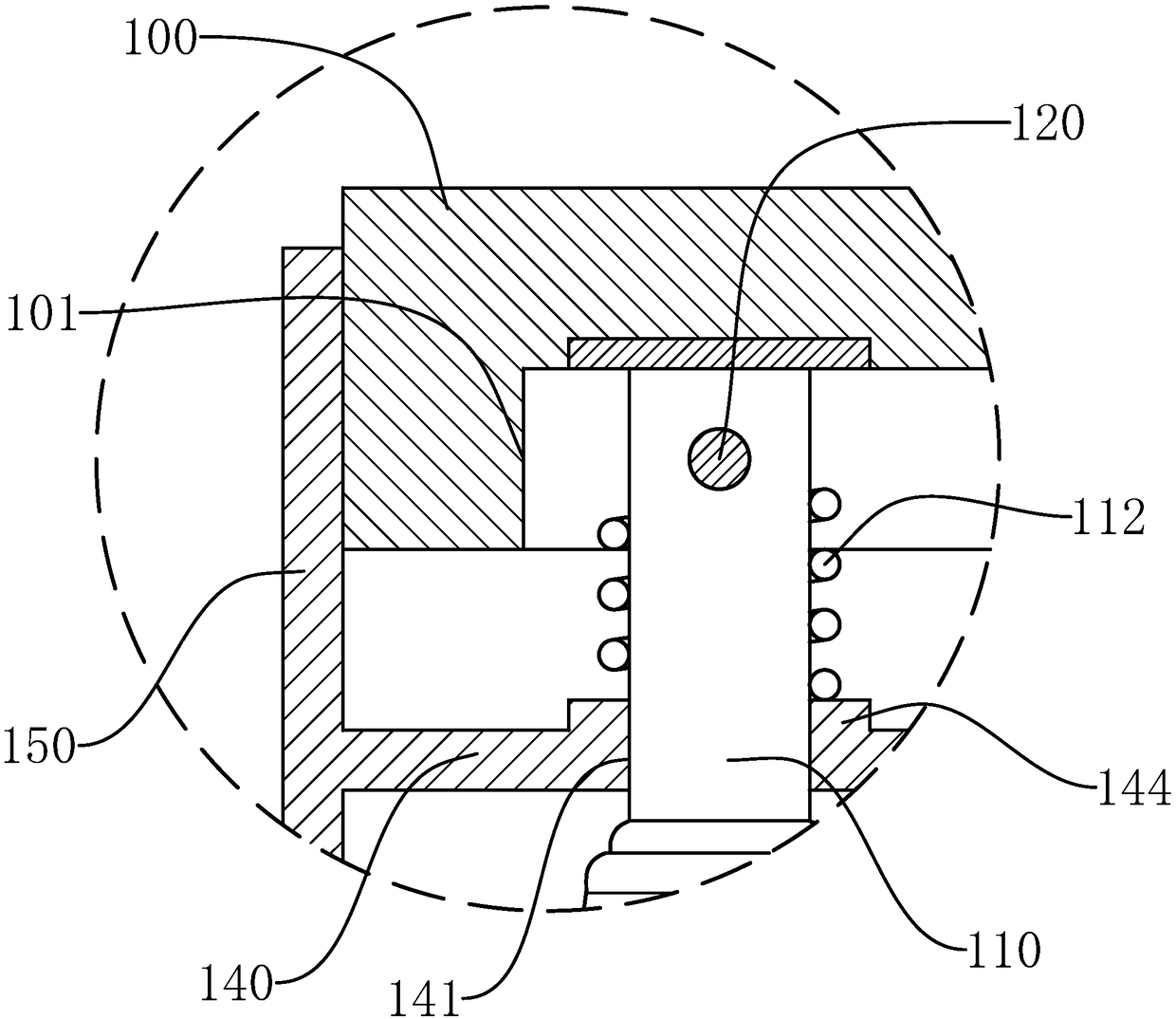

[0056] Such as Figure 1-12 As shown, a pallet for multifunctional logistics of the present invention comprises a rectangular plate-shaped logistics pallet 100, the top surface of the pallet 100 is parallel to the bottom surface, the bottom surface of the pallet 100 is provided with a rectangular plate-shaped plate groove 101, and the bottom surface of the plate groove 101 is connected to the bottom surface of the pallet. The top surface of the supporting plate 100 is parallel, the front, rear, left, and right sides of the plate groove 101 are respectively parallel to the front, rear, left, and right sides of the supporting plate 100, and four roller mechanisms are included. The tops of the four main guide rods 110 corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com