Microsatellite structure suitable for optical load

A micro-satellite and payload technology, which is applied to artificial satellites, space navigation equipment, space navigation vehicles, etc., can solve the problems of increasing structural quality and design complexity, reducing weight and hollowing out design, increasing design difficulty, etc., and achieving good results. Market application prospects, good operation, and the effect of shortening the force transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

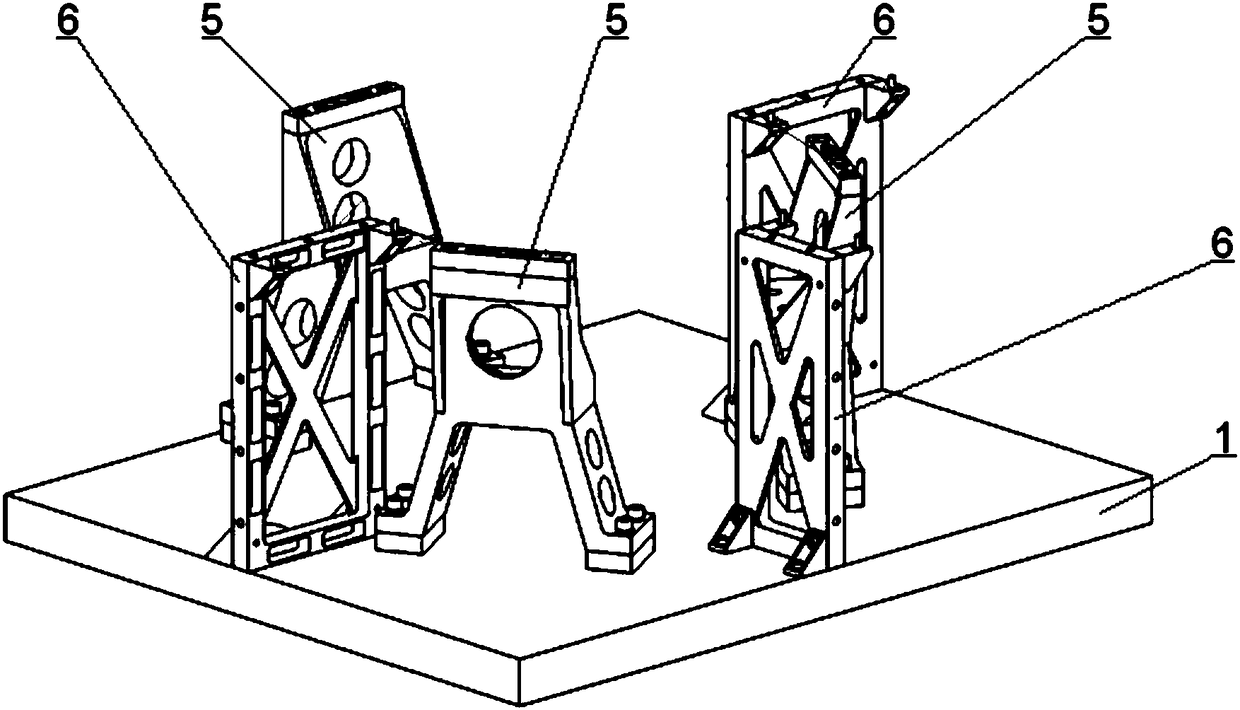

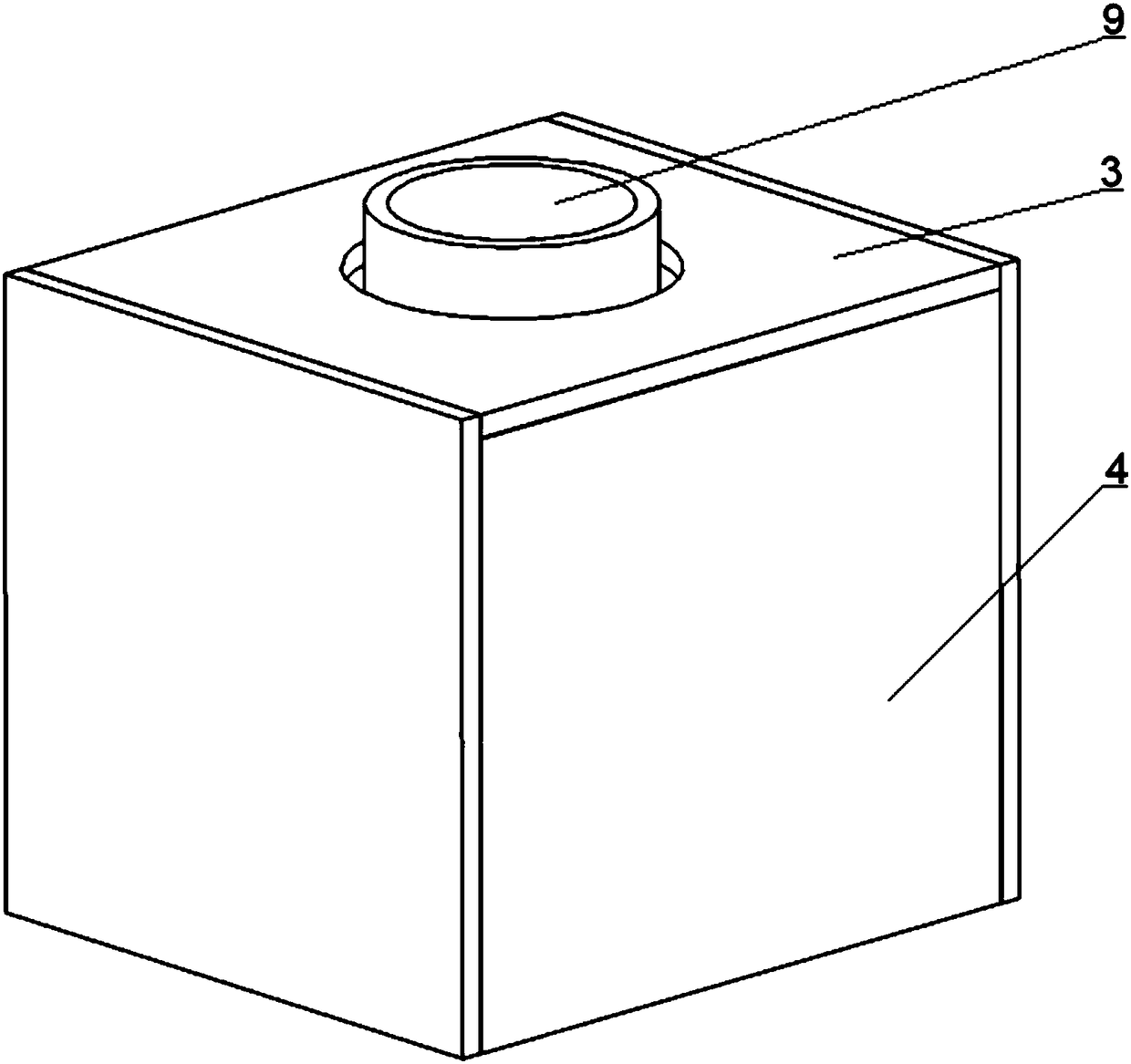

[0026] like Figure 1~3 As shown, a micro-satellite structure suitable for optical loads, including a bottom plate 1, a middle plate 2, a top plate 3, a side plate 4, a bracket 5, a bulkhead 6, a bottom plate strengthening embedded part 7, a docking ring 8 and a load 9; the bottom plate 1. The middle plate 2, the top plate 3 and the side plate 4 all adopt a rectangular plate structure. The bottom plate reinforcement embedded parts 7 for reinforcing the structure are embedded in the bottom plate 1, and the bracket 5 for supporting the load 9 is installed on the upper surface of the bottom plate 1. The bottom surface of the bottom plate 1 is equipped with a docking ring 8; the middle plate 2 and the top plate 3 are provided with through holes for passing through the load 9; Connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com