Cooling device of hydraulic red punching equipment and cooling method thereof

A cooling device and red punching technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of low cooling efficiency, deformation, cooling control of heat-treated products, etc., to achieve improved production efficiency, simple operation, and avoid deformation and the effect of hardness deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

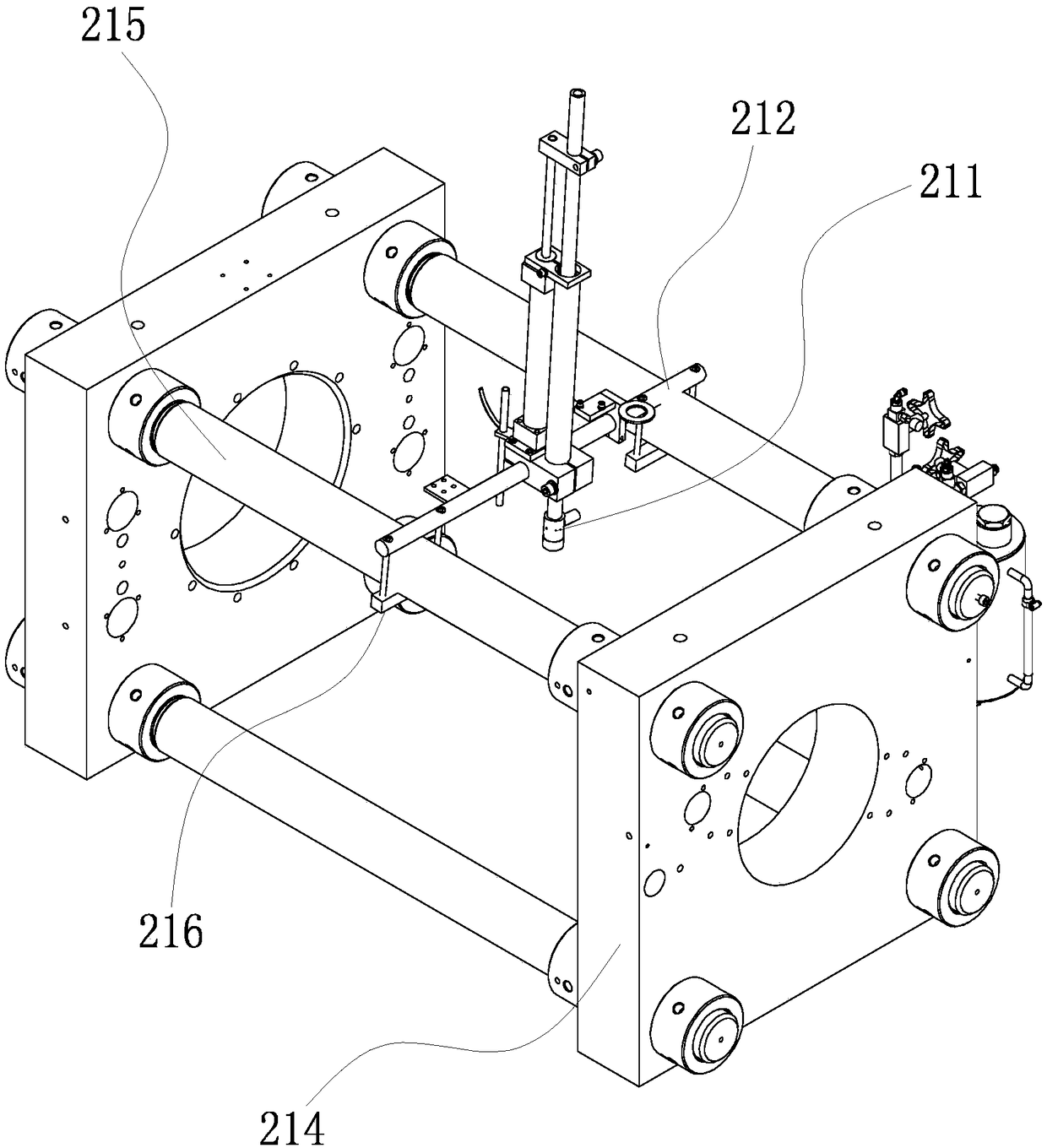

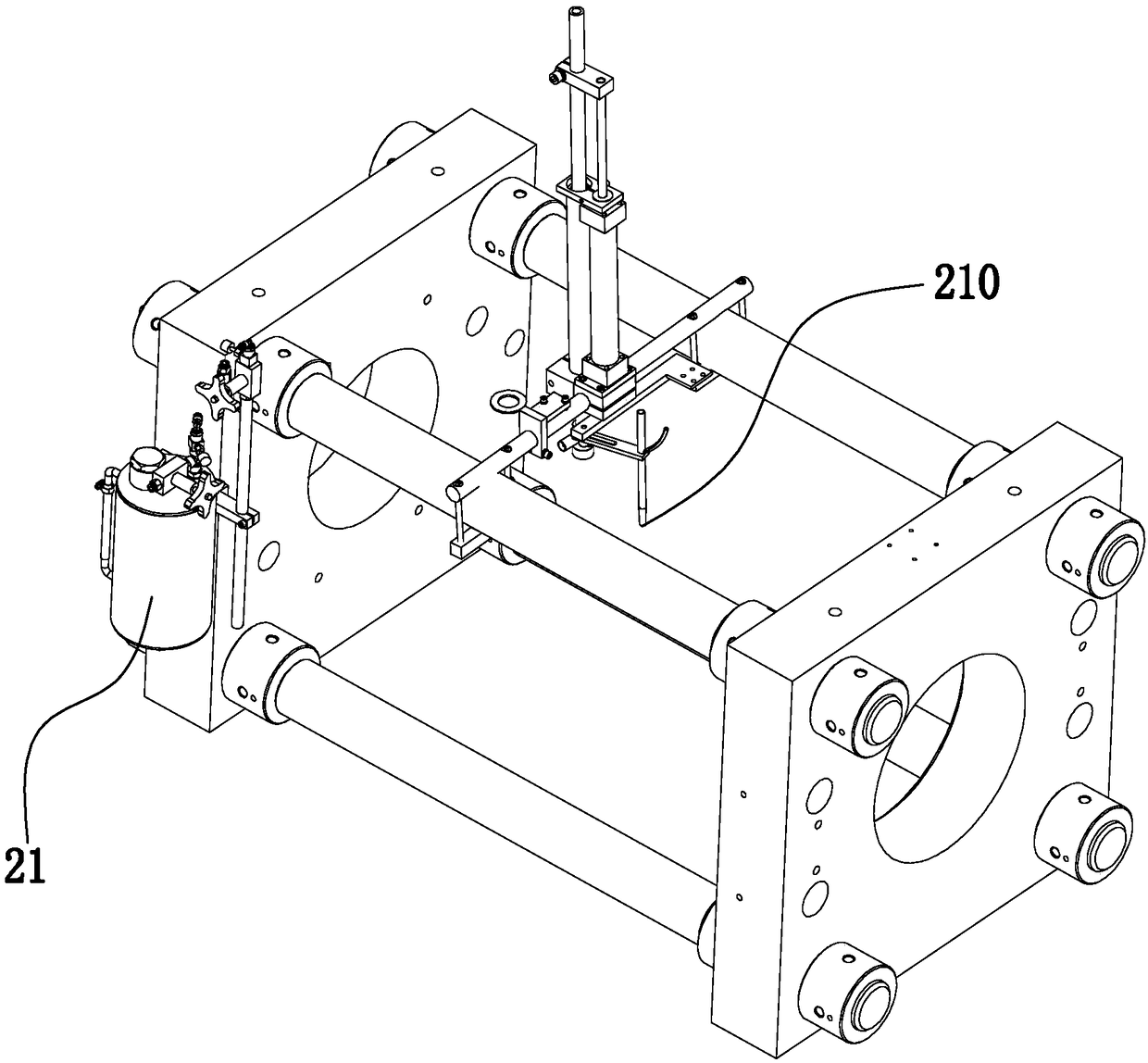

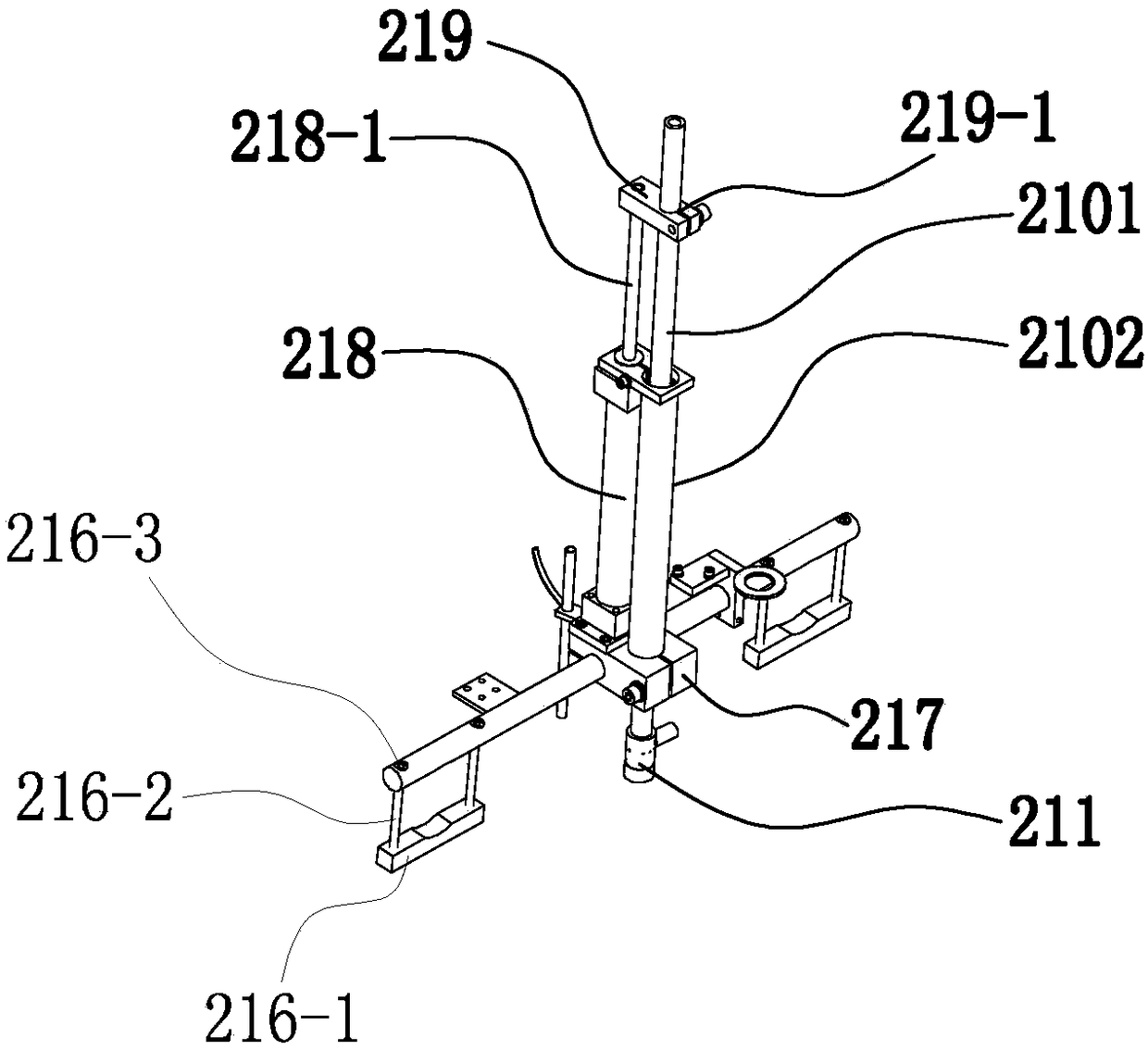

[0031] Example: such as Figure 1-4 As shown, a cooling device for hydraulic red punching equipment includes a spray liquid storage barrel 21, a first nozzle 210 and a second nozzle 211 respectively connected to the spray liquid storage barrel 21; the first nozzle 210 and the second nozzle 211 are arranged in sequence On the left and right sides of 212 with a fixed long axis; the first nozzle 210 corresponds to the position of the stamping head of the hydraulic red punching equipment; it is used to spray the stamping head for cooling; the second nozzle 211 corresponds to the position of the mold cylinder; Spray for cooling the stamped workpiece; after adopting the above structure, the cooling process of the hydraulic red punching equipment can be automatically completed by the machine, the production efficiency is greatly improved, the operation is sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com