Automatic grading machine for removing impurities in grain seeds

A technology for classifying machines and impurities, applied in the field of machinery, can solve the problems of inability to completely clean up other impurities in grain seeds, incomplete cleaning of impurities, and easy mold and deterioration of grain seeds. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

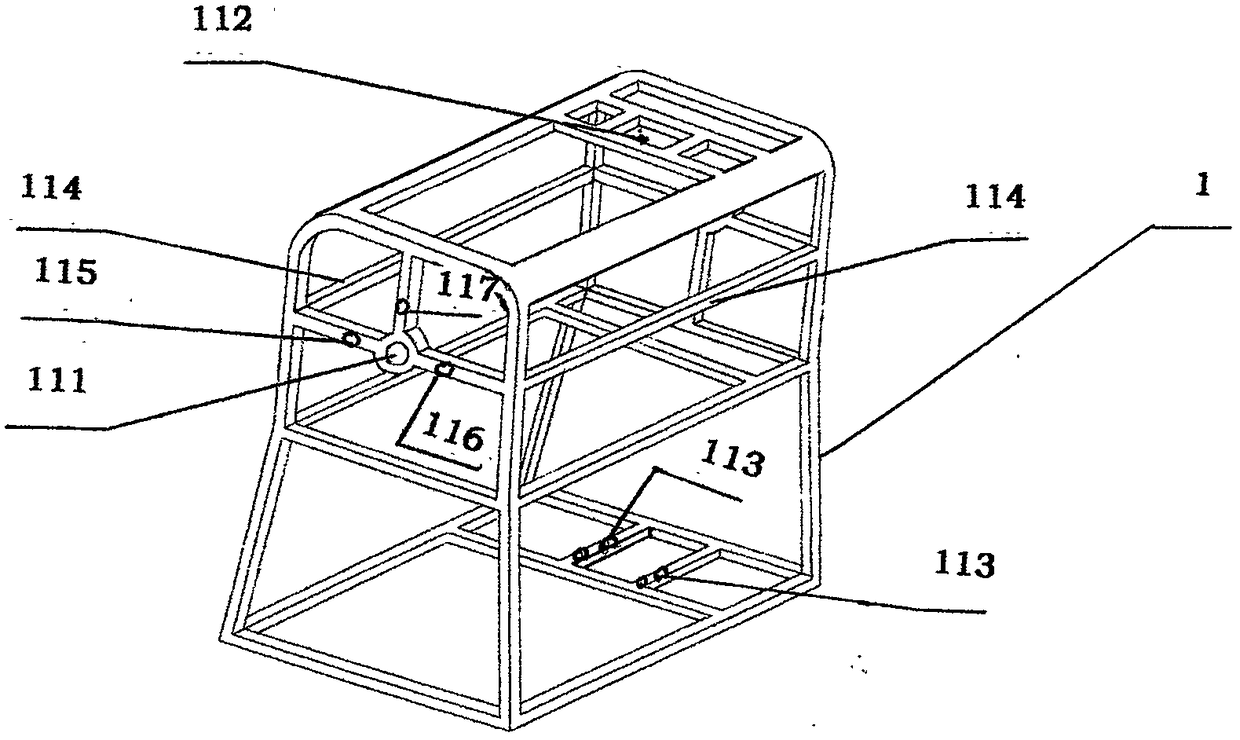

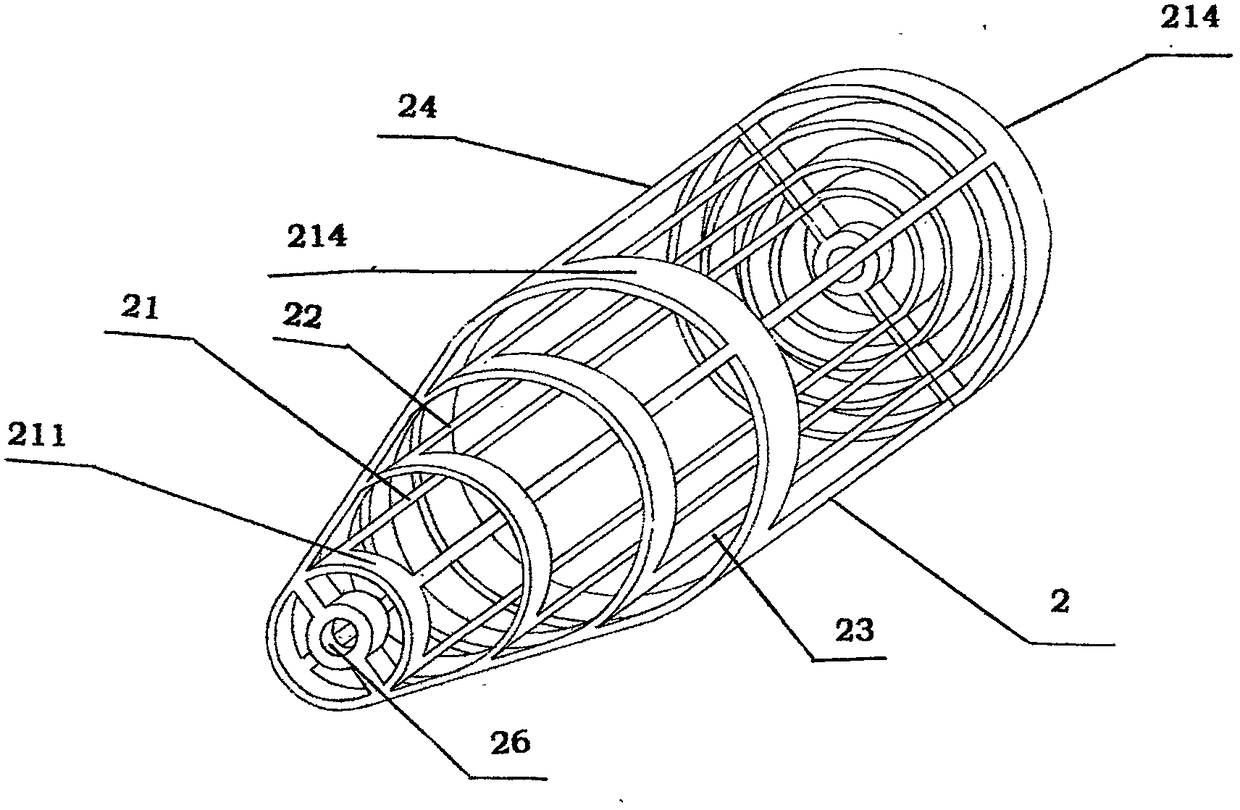

[0019] see Figures 1 to 9As shown, the implementation of the present invention includes an organism 1, a swivel body 2, a swivel shaft 3, a split sleeve 4, a screen 5, a maple impeller 6, a shaft wheel 7, a V-belt 8, a motor 9, a motor wheel 10, a grade box 11, Funnel 12, door 14, impurity cylinder 15, rotating wheel 16, screw rod 17, handle 18, casing 19, small shaft 20, walking wheel 21, gimbal 22, etc.; The corresponding turning beam 21 is connected with the round frame 211 at both ends to form a space for installing the screen, and the screw rod passes through the bead hole and the screen is screwed into the corresponding threaded hole in the turning beam 21; Two groups of corresponding turning beams 22 are connected with the round frames 212 at both ends to form a space for installing screens, and the screw rods pass through the bead holes and the screens are screwed into the corresponding threaded holes in the turning beams 22; Be provided with two groups of correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com