Method for improving screening efficiency of vibrating screen

A vibrating screen and screening technology, applied in chemical instruments and methods, filter screens, solid separation, etc., can solve the problems of large vibration load, low screening efficiency and uneven force of the original crushing vibrating screen, so as to improve the vibration Screening efficiency and service life, the effect of improving vibrating screening efficiency and improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

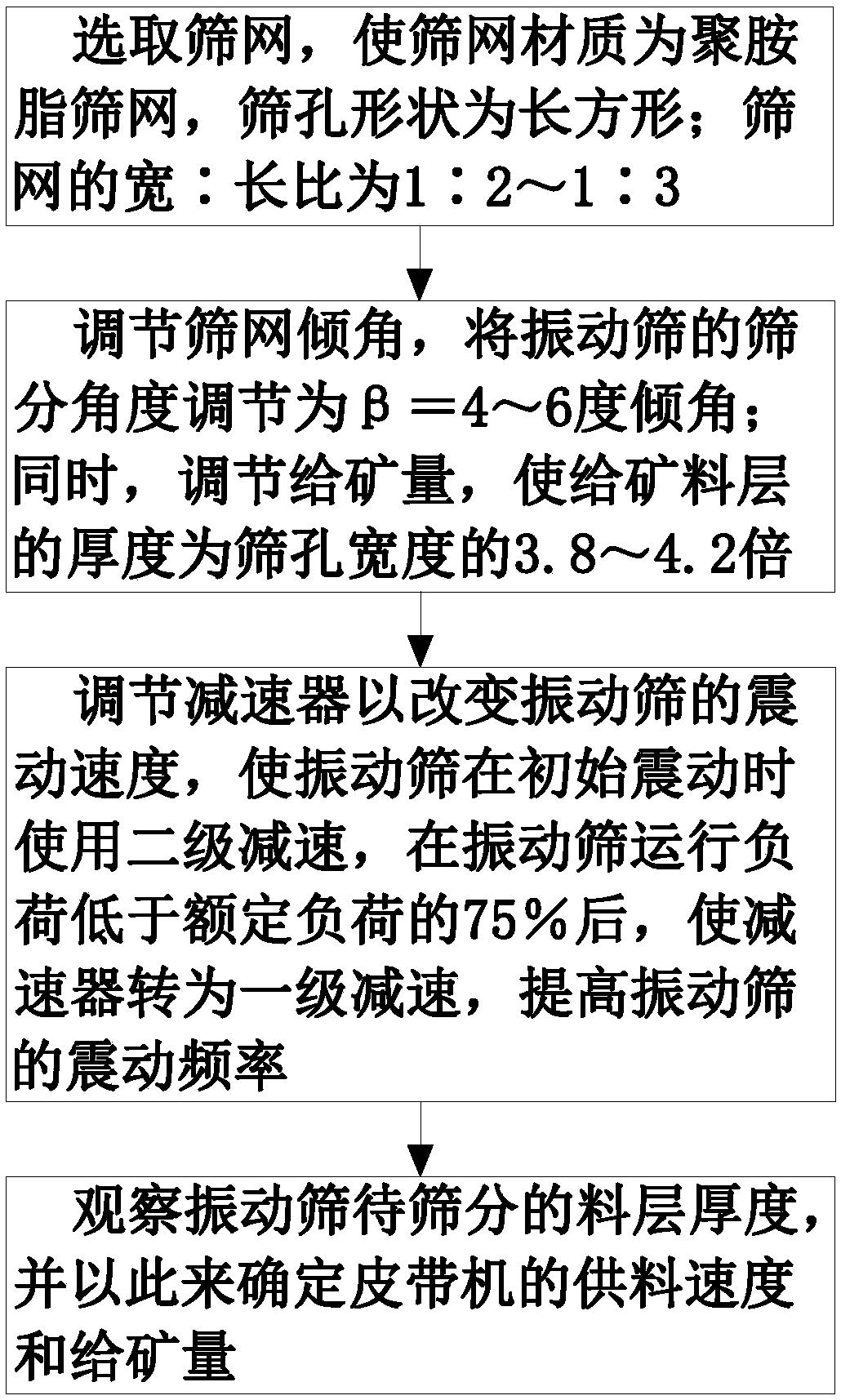

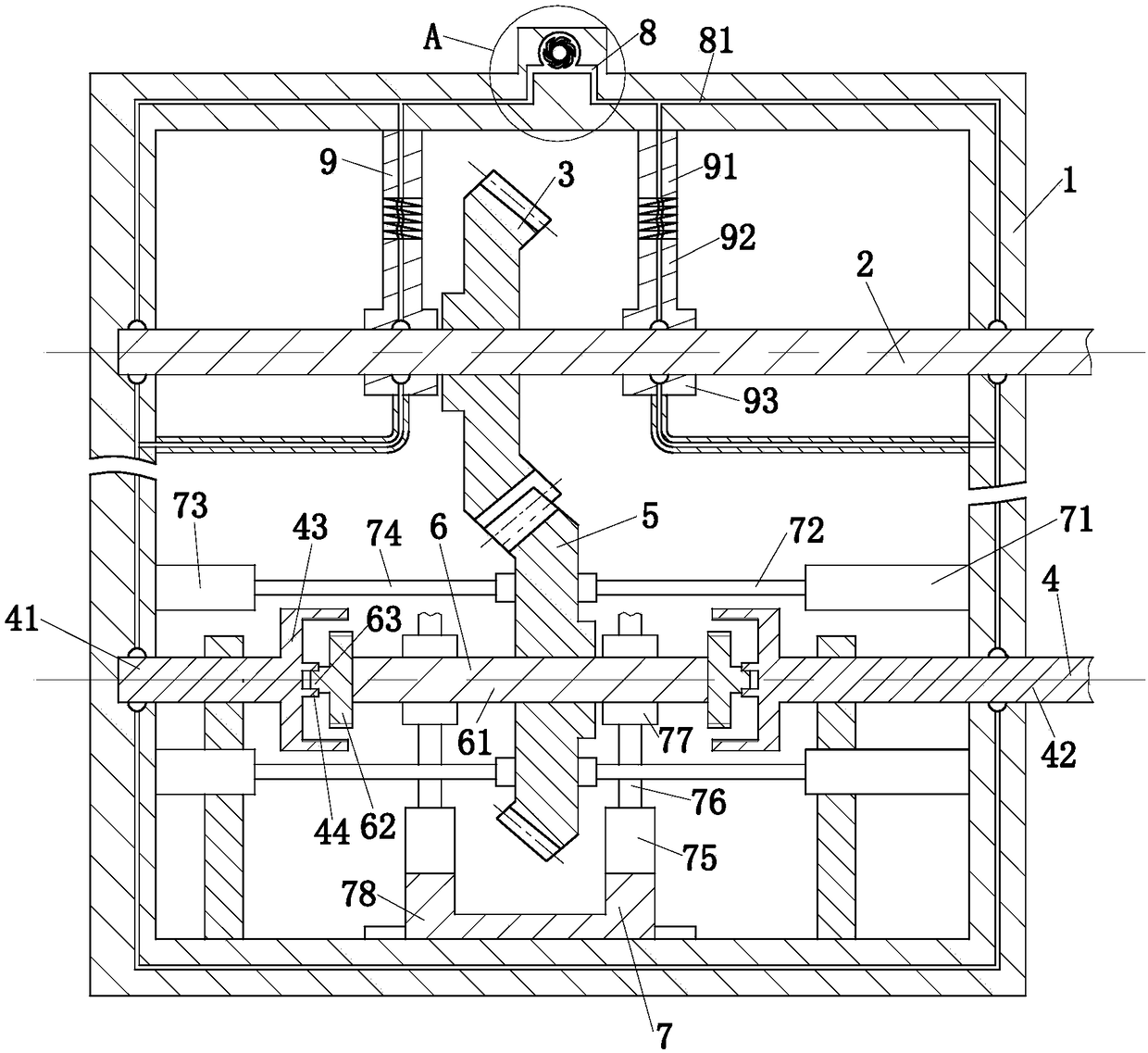

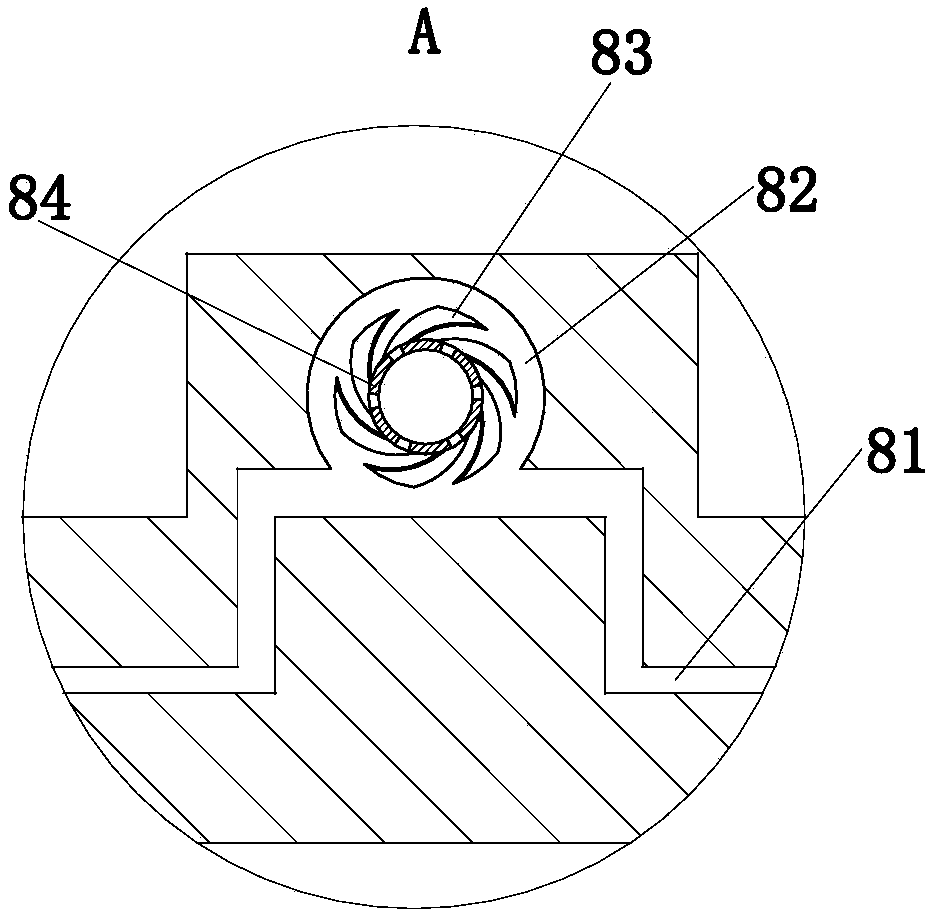

[0029] use Figure 1 to Figure 7 The method for improving the screening efficiency of a vibrating screen according to an embodiment of the present invention will be described as follows.

[0030] Such as figure 1 As shown, a method for improving the screening efficiency of a vibrating screen according to the present invention includes a screen, a belt conveyor and a reducer connected to a motor, and the method for improving the screening efficiency of a vibrating screen includes the following steps:

[0031] Step 1: Select the screen, make the material of the screen is polyurethane screen, the shape of the screen is rectangular; the width:length ratio of the screen is 1:2~1:3;

[0032] Step 2: After step 1 completes the selection of the screen, adjust the inclination of the screen, and adjust the screening angle of the vibrating screen to β = 4 to 6 degrees to extend the ore screening time on the screen and reduce the crushing and screening Cycle load; at the same time, adjust the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com