Planet gear differential for vertical liquid-solid centrifuge and vertical liquid-solid centrifuge

A planetary gear and planetary gear shaft technology, which is applied in the field of separators, can solve the problems of increasing the cost of planetary gear differential separators, high cost of separator maintenance or parts replacement, and high processing difficulty, so as to reduce production and maintenance costs. , compact structure, the effect of increasing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

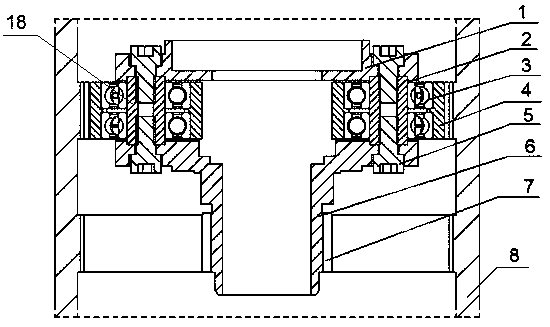

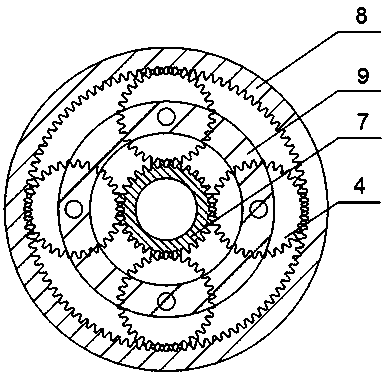

[0033] Such as figure 1 , 2 The shown planetary gear differential for a vertical liquid-solid centrifuge includes an outer ring gear 8, a planetary gear carrier 9, a planetary gear 4, and a sun gear 7, and the planetary gear 4 meshes with the outer ring gear 8 and the sun gear 7 , the planetary gear carrier 9 is composed of an upper flange 1 and a lower flange 6, the lower part of the upper flange 1 is processed with 4 circular grooves, the depth of the groove is 6~15mm, and the upper part of the lower flange 6 corresponds to The circular grooves of the upper flange are processed with equal number and equal width circular grooves, and the depth of the grooves is 8~20mm. The planetary gear shaft 18 is installed between the upper and lower flanges of the planetary gear carrier, and the upper and lower ends of the planetary gear shaft 18 are respectively located in the circular groove of the upper flange and the circular groove of the lower flange. Double bearing is installed i...

Embodiment 2

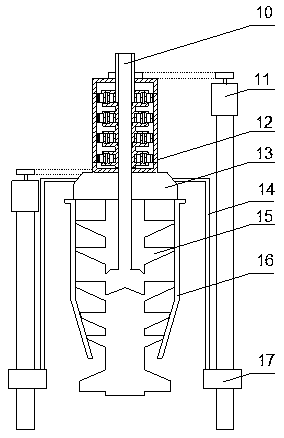

[0035] The present invention proposes a vertical liquid-solid centrifuge, the top of which is equipped with a multi-stage planetary gear differential 12, and the planetary gear differentials of each stage in the multi-stage planetary gear differential are coaxially installed, and the first-stage planetary gear The sun gear of the differential is the input shaft of the multi-stage planetary gear differential, and the planetary gear carrier of the adjacent upper-stage planetary gear differential is integrally processed or patterned with the sun gear of the adjacent next-stage planetary gear differential. The key transmission connection, the planetary gear carrier of the last stage planetary gear differential is the output shaft of the multi-stage planetary gear differential. The multi-stage planetary gear differential is composed of 3-stage to 5-stage planetary gear differential sets, and the transmission ratio can reach 1:64~1:1024.

[0036] Such as image 3As shown, the multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com