Low energy consumption water-saving type flue gas de-whitening device and method

A water-saving and low-energy-consumption technology, which is applied in the field of low-energy-consumption and water-saving flue gas dewhitening devices, can solve problems such as unfavorable water removal, reduce relative humidity of flue gas, reduce saturation, etc. Air temperature, the effect of reducing the proportion of water vapor content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

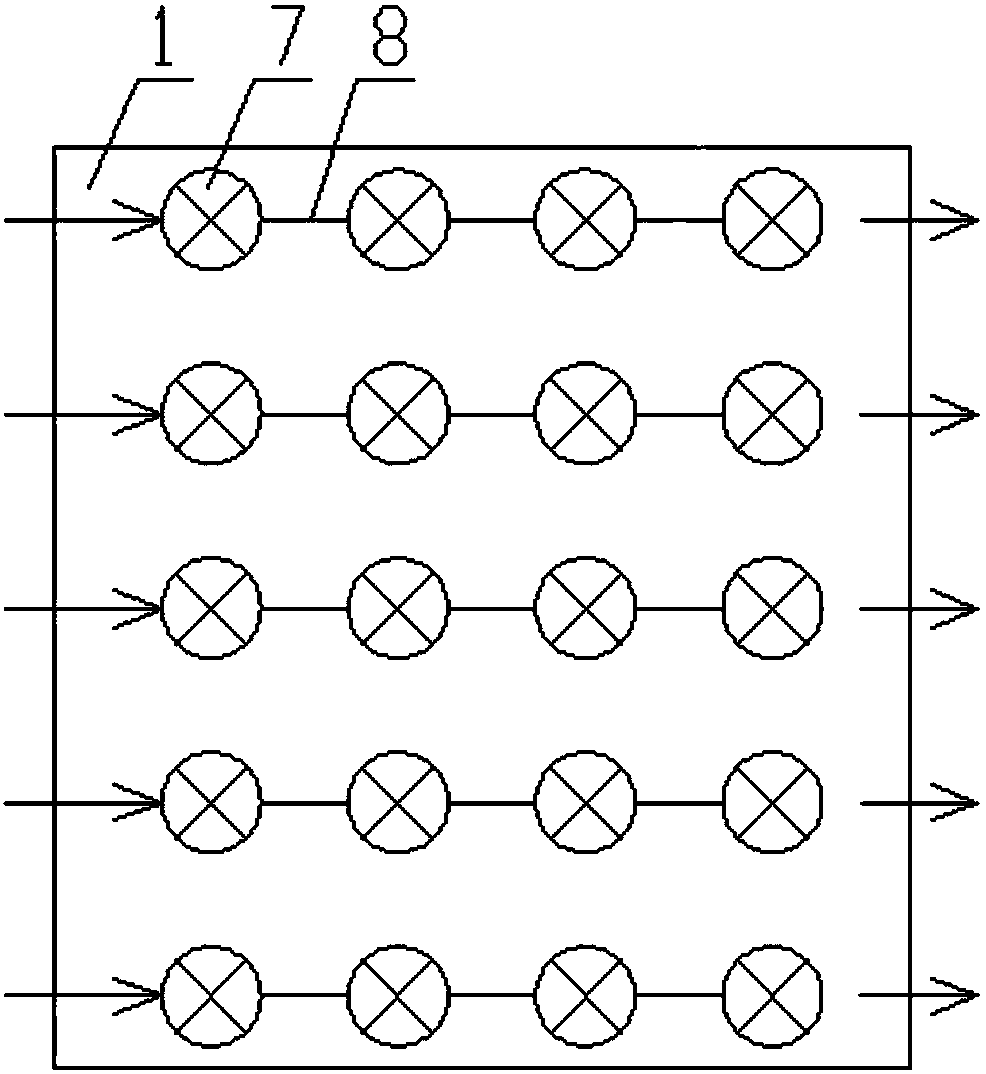

[0039] Embodiment 1, low energy consumption and water saving type flue gas dewhitening device, such as Figure 1-3 As shown, it includes a heat exchanger 1 , a fan 2 , a flue gas duct 3 , a water collector 4 , a hot air pipe 5 , a mixed air duct 6 , a centrifugal separation pipe 7 and a heat exchange fin 8 .

[0040] Both sides of the heat exchanger 1 communicate with the fan 2 and the hot air pipe 5 respectively. The heat exchanger 1 is equipped with an airflow uniform plate 21 at the cold air inlet and the cold air outlet (the connection between the heat exchanger 1 and the fan 2 and the connection between the heat exchanger 1 and the hot air pipe 5), and the air flow is evenly distributed. The plate 21 can make the cold air entering the heat exchanger 1 more uniform.

[0041] Several (at least two) centrifugal separation groups are arranged in parallel in the heat exchanger 1, and the distance between each centrifugal separation group is 5-10 mm. The centrifugal separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com