Grain fumigating device for reducing insecticidal gas residues

A technology of a fumigation device and a gas generating device, which can be applied to devices for capturing or killing insects, using chemicals to preserve seeds, animal husbandry, etc. The gas is not easy to discharge and other problems, to achieve the effect of quickly reaching the gas environmental protection standard, prolonging the maintenance period, and avoiding the harm to the human body and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

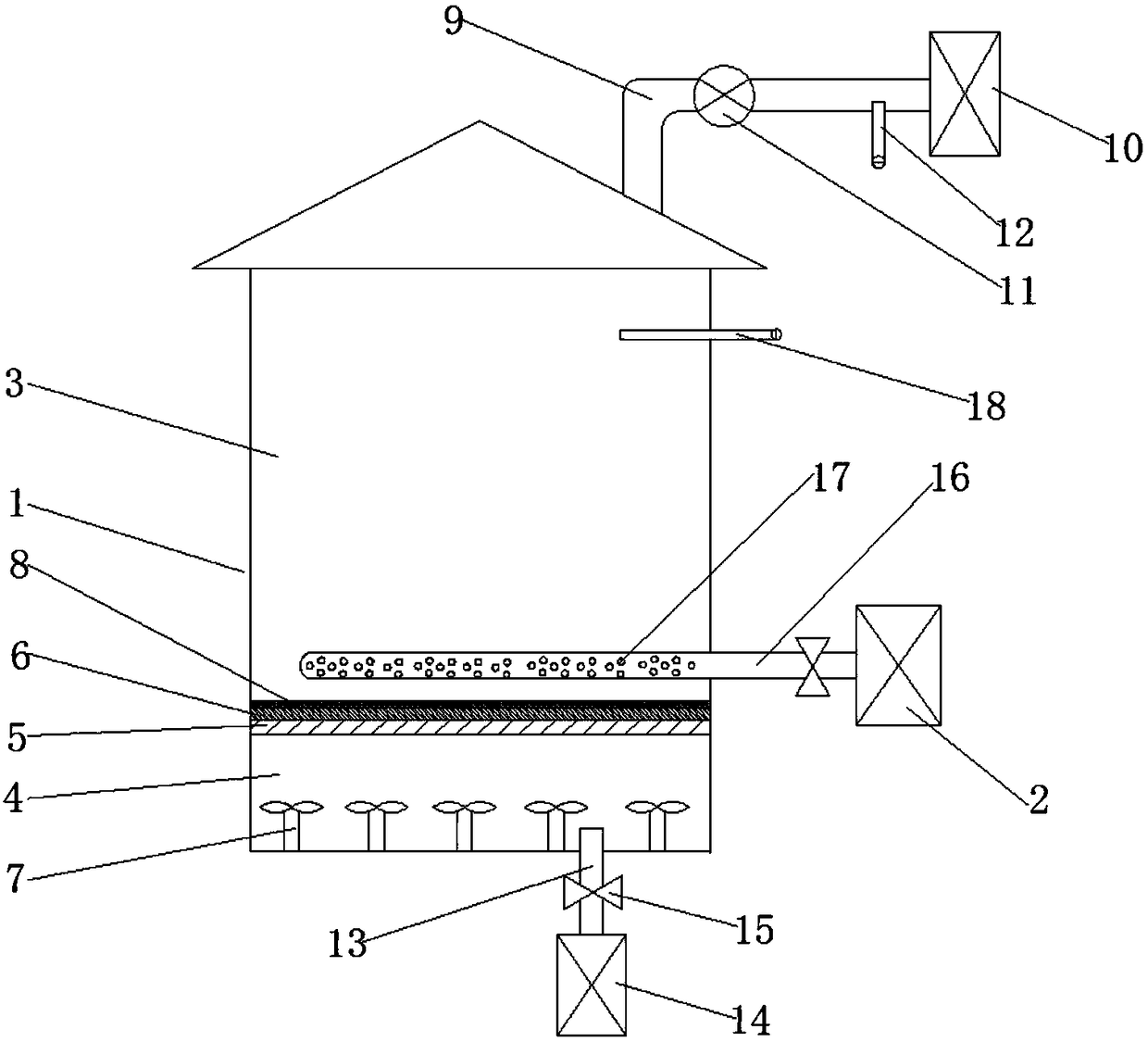

[0018] Such as figure 1 The illustrated grain fumigation device for reducing insecticidal gas residues includes an insecticidal gas generating device 2 located outside a granary 1. The granary 1 includes a grain storage cavity 3 and a ventilating cavity 4 arranged up and down. The insecticidal gas The generating device 2 is connected to the grain storage cavity 3, a mesh plate 5 is arranged between the grain storage cavity 3 and the ventilation cavity 4, and a filter screen 6 is laid on the mesh plate 5, the filter screen The aperture of 6 is not larger than the grain size, the ventilation cavity 4 is provided with an air intake mechanism communicating with the outside of the granary 1, a plurality of fans 7 are arranged inside the ventilation cavity 4, and the upper part of the granary 1 is also provided with An exhaust device connected to the outside of the granary 1.

[0019] In the above-mentioned grain fumigation device, the gas introduced through the ventilation cavity 4 d...

Embodiment 2

[0021] Based on Example 1, such as figure 1 As shown, the filter screen 6 is also provided with at least one layer of filter cloth 8, and the pore size of the filter cloth 8 is not larger than the pore size of the filter screen 6. The filter cloth 8 is provided to prevent dust and impurities in the grain from entering the ventilating cavity 4, resulting in the accumulation of dust in the ventilating cavity 4, increasing the life of the equipment and extending the maintenance period.

Embodiment 3

[0023] Based on Example 1, such as figure 1 As shown, the exhaust device includes an exhaust pipe 9 communicating with the inside of the granary 1 and a gas purifier 10 connected to the exhaust pipe 9, and the exhaust pipe 9 is provided with an induced draft fan 11 and a first gas Concentration sensor 12. By installing an exhaust device and installing a gas scrubber 10 in the exhaust device, the phosphine gas after the fumigation can be quickly discharged, so that the gas inside the granary 1 reaches a safe range, and the discharged phosphine gas is purified at the same time Emission to avoid the hazards of highly toxic gases to the human body and the environment, and the first gas concentration sensor 12 monitors the discharged gas in real time to reach the safety emission index, which solves the danger caused by the natural emission of phosphine gas after the existing grain fumigation High degree of problems.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com