Mixed powder for powder metallurgy

A technology of mixed powder and powder metallurgy, which is applied in lubricating compositions, metal processing equipment, transportation and packaging, etc., and can solve problems such as insufficient processability, inability to withstand, and easy damage

Active Publication Date: 2020-10-27

JFE STEEL CORP

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in general, green compacts before sintering are often brittle and have insufficient workability

That is, the green compact before sintering cannot withstand the stress applied to the jig during green processing or during cutting, and is easily damaged.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

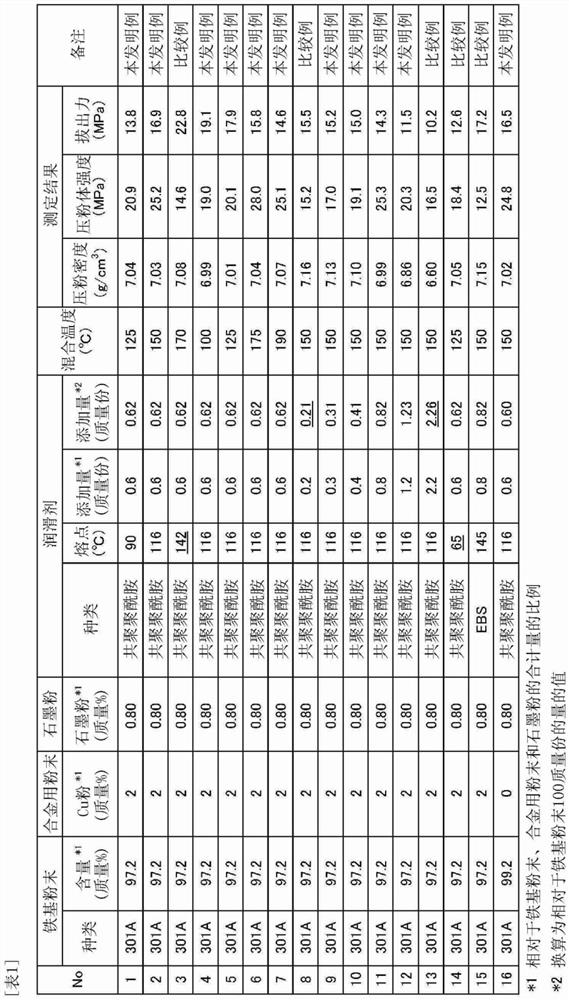

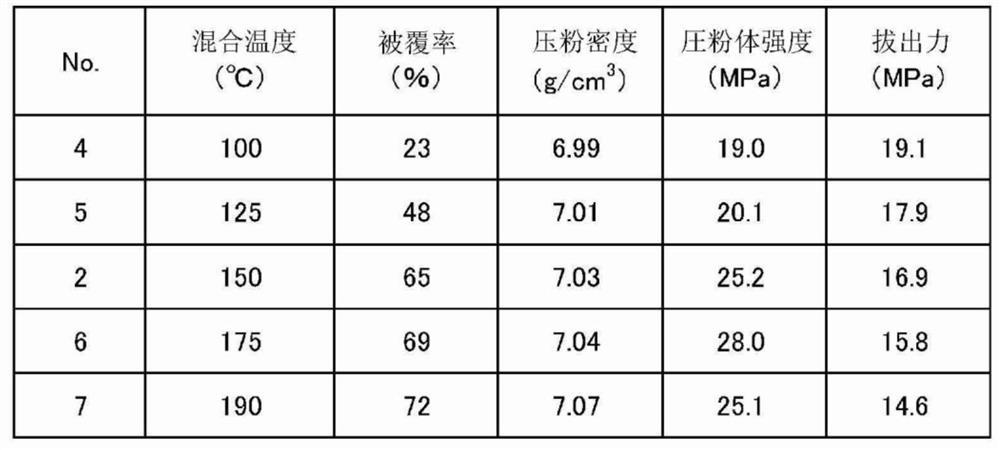

[0058] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited to the following example.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

The present invention provides a mixed powder for powder metallurgy having excellent green compact strength and extractability. The mixed powder for powder metallurgy contains iron-based powder and copolyamide, the amount of the copolyamide is 0.3-2.0 parts by mass relative to 100 parts by mass of the iron-based powder, and the melting point is 80-120°C.

Description

technical field [0001] The present invention relates to a mixed powder for powder metallurgy, and in particular to a mixed powder for powder metallurgy which is excellent in extractability and strength of a green compact when press-molded to form a compact. powder. Background technique [0002] Powder metallurgy is a technique for producing sintered parts such as mechanical parts by sintering the green compact after press-molding mixed powder containing iron-based powder and the like to obtain a green compact. In recent years, due to the advancement of powder metallurgy technology, complex-shaped sintered parts can be manufactured into near-net shapes with high dimensional accuracy, and powder metallurgy technology is being used in the manufacture of products in various fields. [0003] However, for sintered parts, when extremely strict dimensional accuracy is required, or when a horizontal hole shape, an undercut shape, or other highly complicated shapes are required, post...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22F1/00B22F1/02B22F3/02C10M107/44C10M111/04C10M103/02C10N20/00C10N30/00C10N40/00C22C38/00B22F1/06B22F1/10B22F1/102B22F1/105B22F1/16

CPCB22F3/02C22C38/00B22F9/082C22C33/02B22F2998/10B22F2999/00C10M169/04C10M2201/041C10M2217/044C10M2201/05C10M2201/053C10N2020/06C10N2040/20C10N2050/08B22F1/102B22F1/16B22F1/06B22F1/10B22F1/105B22F3/10C10M103/02C10M107/44B22F2301/35C08K9/08B22F2003/023B22F3/16C08K3/04C08K3/08C08L77/00C10M125/02C10M111/04C10M2201/0413C10M2217/0443

Inventor 宇波繁平山従仕

Owner JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com