A construction method for a large-section subway crossing tunnel

A construction method and large-section technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as high support difficulty, increased construction risks, and impact on the surrounding environment, so as to reduce the surface construction site area and save Part of the ground area, the effect of reducing the amount of earthwork excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further illustrate the features of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. The accompanying drawings are for reference and description only, and are not intended to limit the protection scope of the present invention.

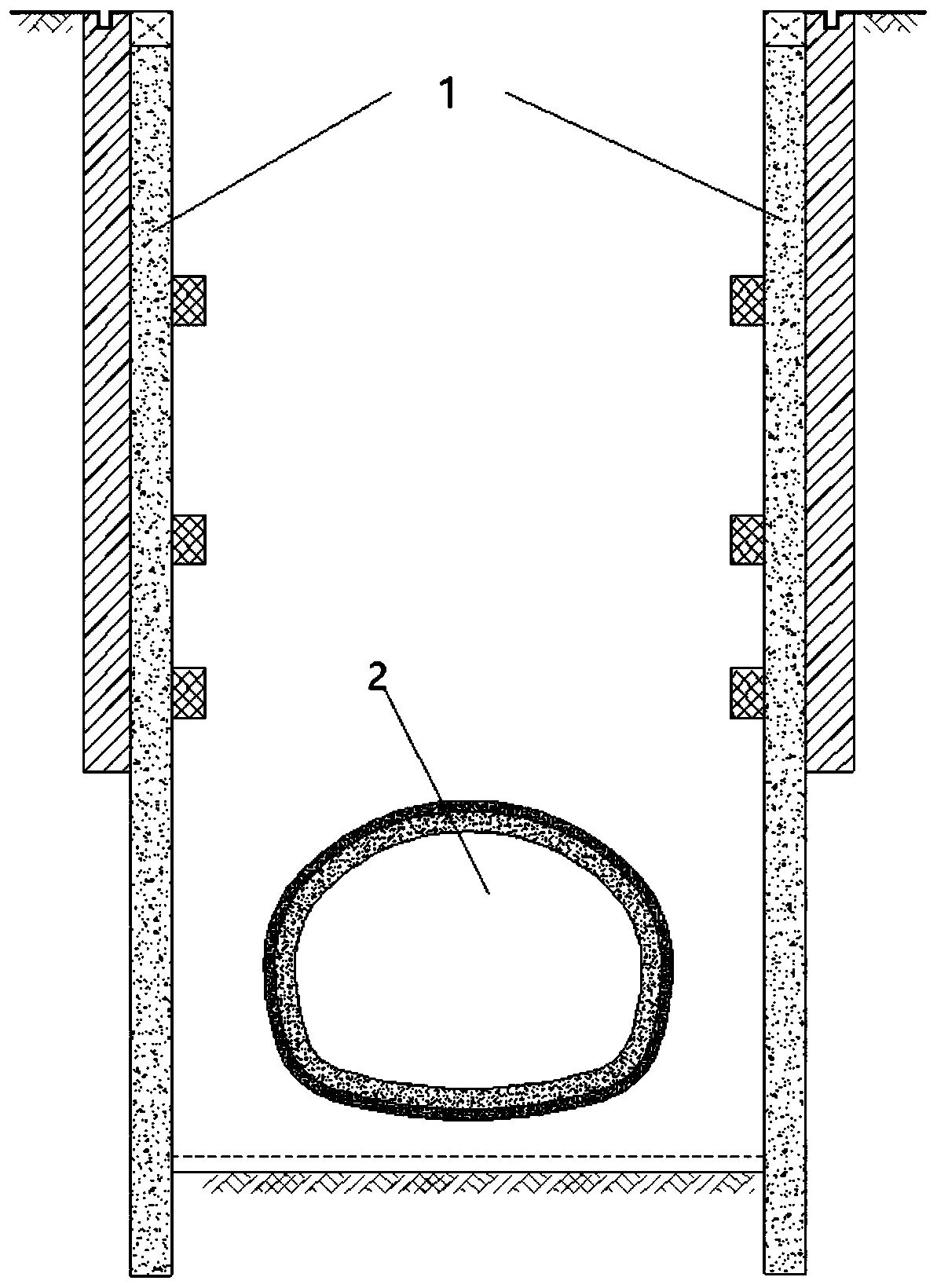

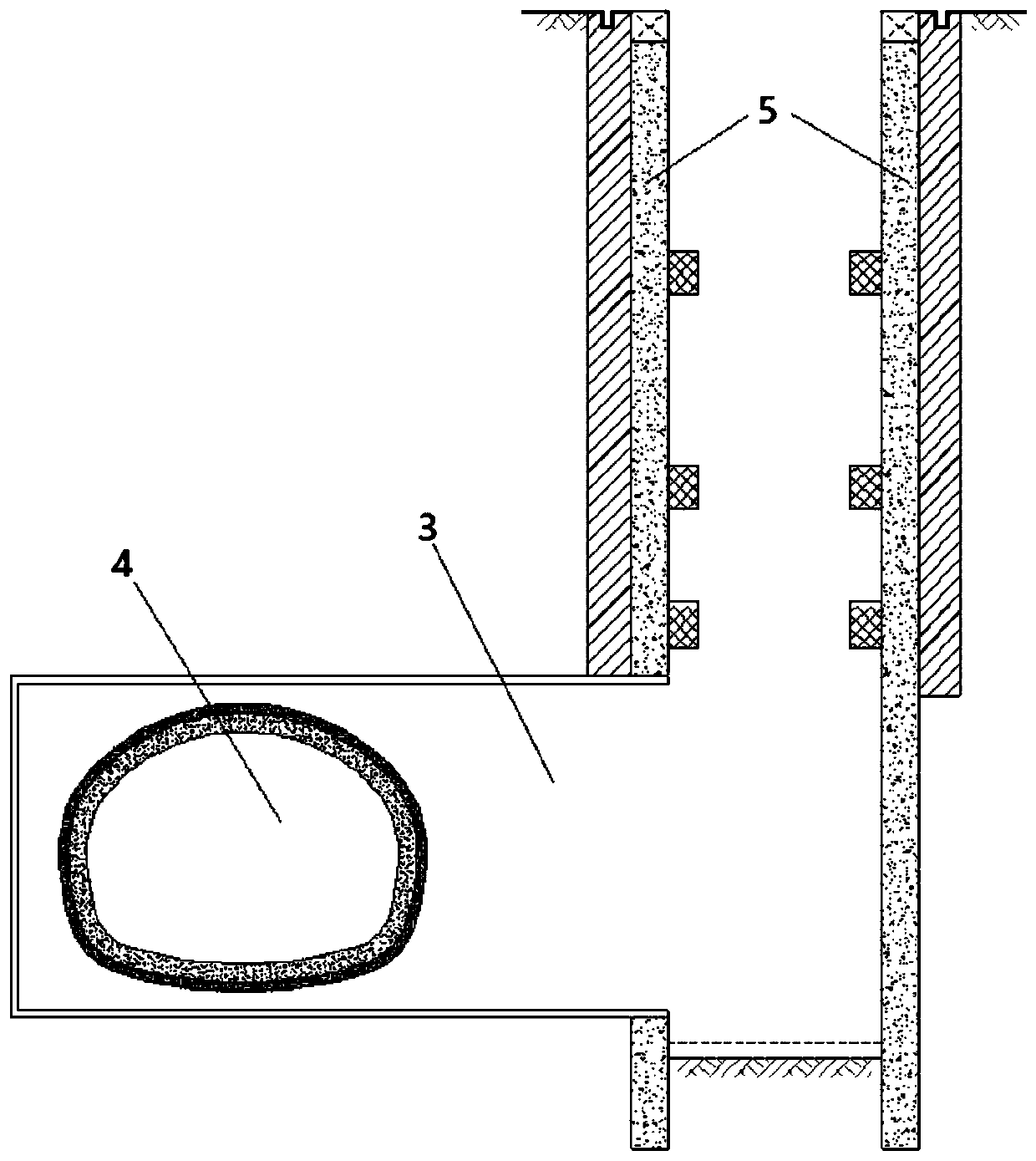

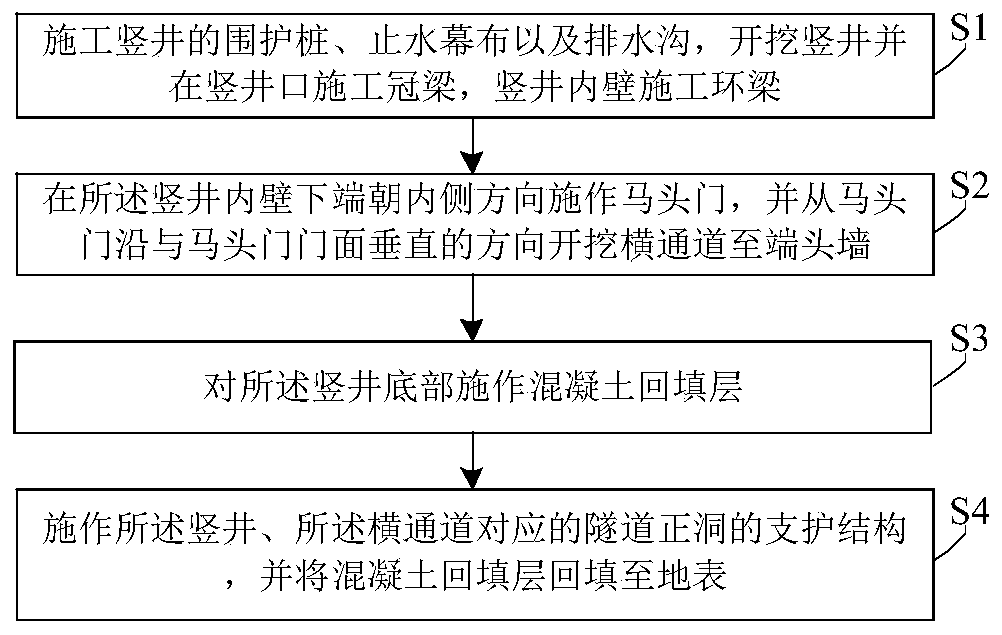

[0046] refer to Figure 3 to Figure 4 As shown, this embodiment discloses a construction method for a large-section subway crossing tunnel, including the following steps S1 to S4:

[0047] S1. Construct the retaining piles, water-stop curtains and drainage ditches of the shaft, excavate the shaft and construct the crown beam at the shaft mouth, and construct the ring beam on the inner wall of the shaft;

[0048] S2. Build a horse head gate at the lower end of the inner wall of the shaft towards the inside, and excavate a cross passage from the horse head gate to the end wall along the direction perpendicular to the horse head gate facade;

[0049] S3, appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com