Earthwork transportation system used for foundation pit engineering and construction method

A transportation system and foundation pit technology, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of earth lifting, small transfer space, difficult operation of large-scale earth borrowing equipment, huge dust and haze, etc., and achieve the construction progress. Efficient operation, high environmental protection value, and the effect of reducing dust and haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

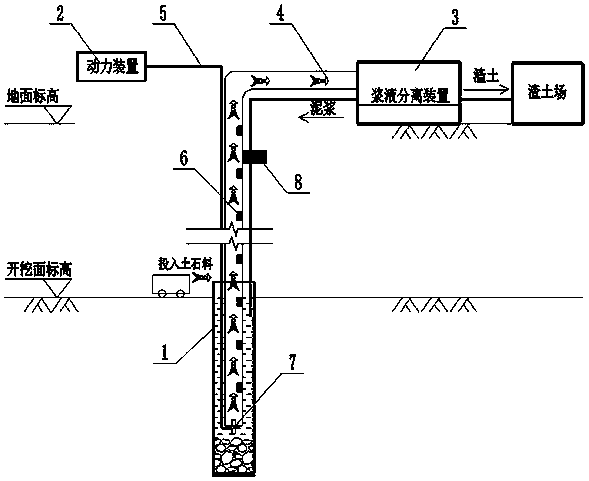

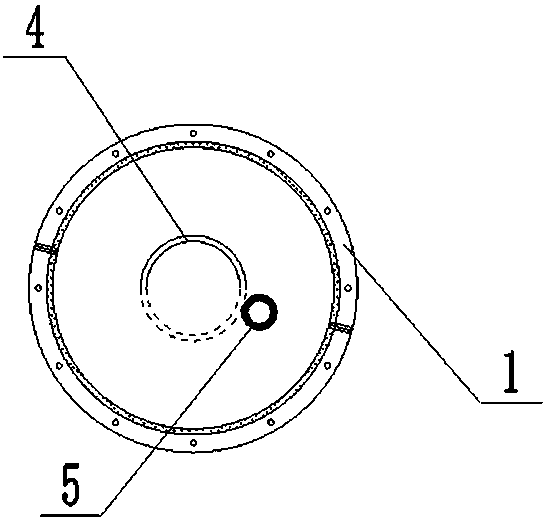

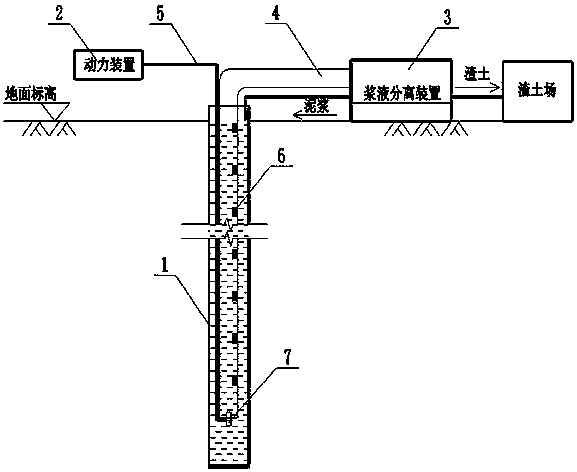

[0029] Such as figure 1 As shown, it is a schematic diagram of the overall structure of an earthwork transportation system used in foundation pit engineering according to the present invention. The system includes a steel casing 1, a power device 2, a slurry separation device 3, a conduit 4, an air pipe 5, and an anti-blocking pipe device 6. Gas-liquid mixer 7 and fixed support structure 8 .

[0030] The steel casing 1 is buried in the soil, and the casing is filled with mud and earthwork mixture to provide a safe and stable operating environment for the entire transportation system, and will be gradually removed later with the excavation of the earthwork.

[0031] The power unit 2 is an air compressor, which is connected with the transportation system through the air pipe 5, and provides the power required for transportation for the whole system.

[0032] The slurry separation device 3 is composed of a slurry pipe, a slurry pump and a slurry separator, which mainly completes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com