An integrated equipment for processing round steel bars and straight screw bars

A technology for processing equipment and steel bars, which is applied in the field of integrated equipment for the processing of coiled steel bars and straight screw steel bars, can solve the problems of difficult straightening and adjustment, poor steel processing quality, and large space occupation, so as to improve equipment utilization and production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

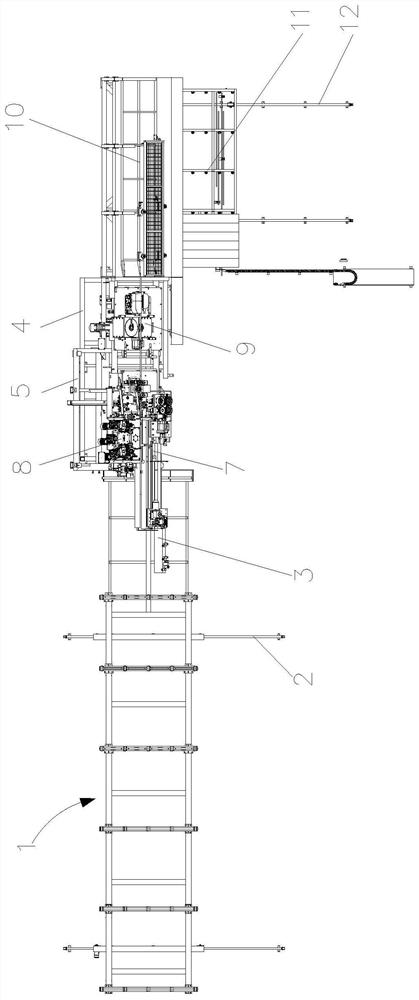

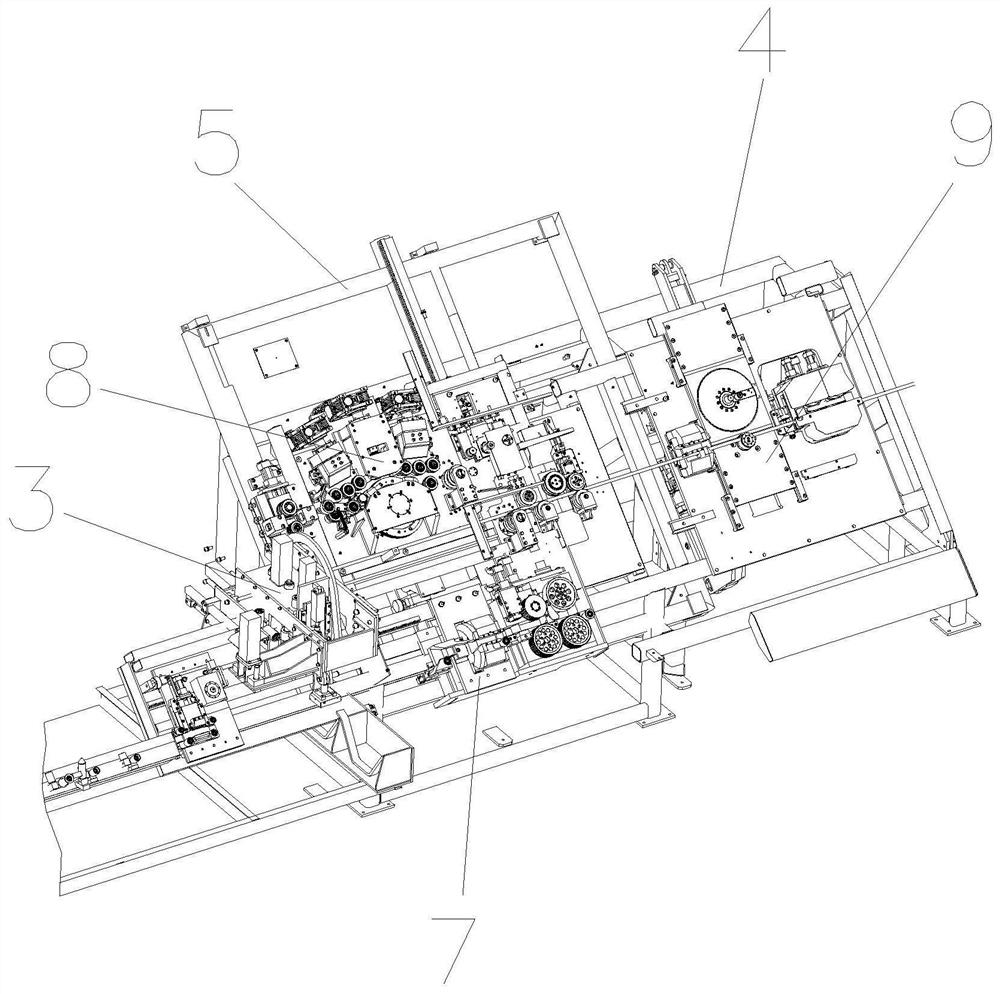

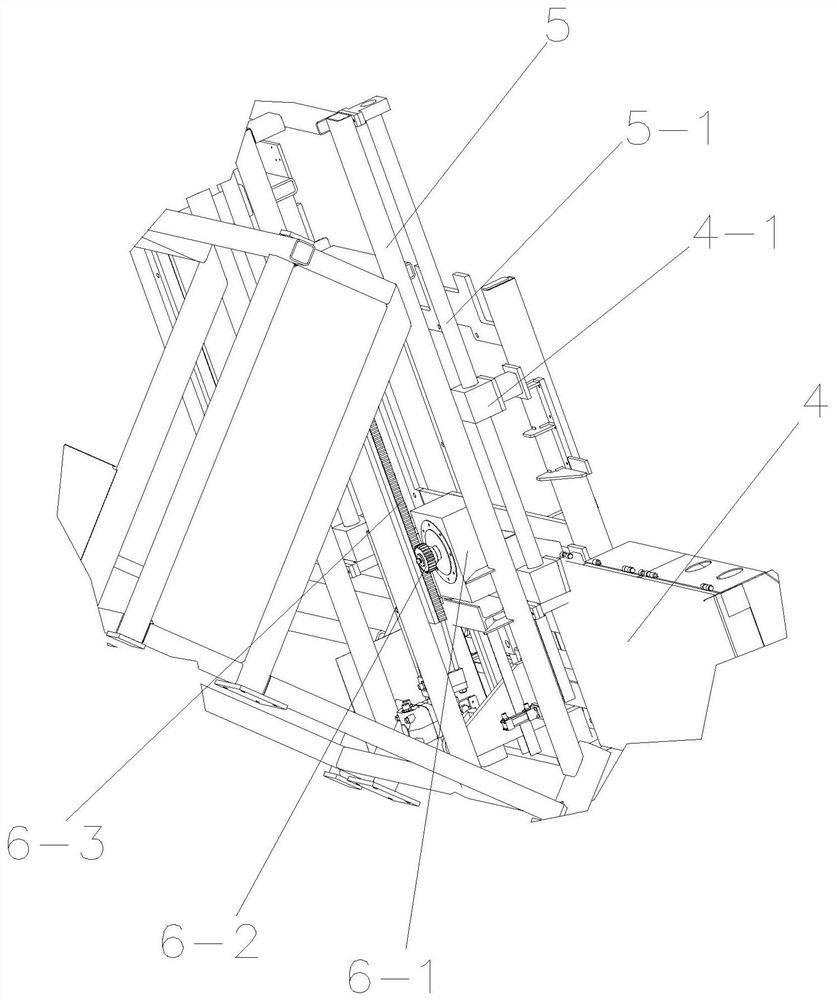

[0062] Such as figure 1 and figure 2 As shown, the present invention includes main body processing equipment, and one side of the main body processing equipment is equipped with a round steel bar pay-off rack, a multi-position straight screw steel bar storage device and a magnetic suction feeding device for magnetically moving straight screw steel bars 3. The other side of the main body processing equipment is equipped with a product collection device. The main body processing equipment includes a right-angled trapezoidal fixed frame 4, a mobile frame 5 installed on the slope of the right-angled trapezoidal fixed frame 4, and all installed on the The straight screw steel bar preprocessing device 7 and the round steel bar straightening device 8 on the mobile frame 5, the right angle trapezoidal fixed frame 4 is equipped with a shear bending return device 9 near the side of the product collection device, the The mobile frame 5 can move up and down along the slope of the right-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com