Atomic layer deposition online monitoring system

An atomic layer deposition and monitoring system technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of passive and delayed risk, insufficient effective monitoring and recording, and rigid maintenance process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

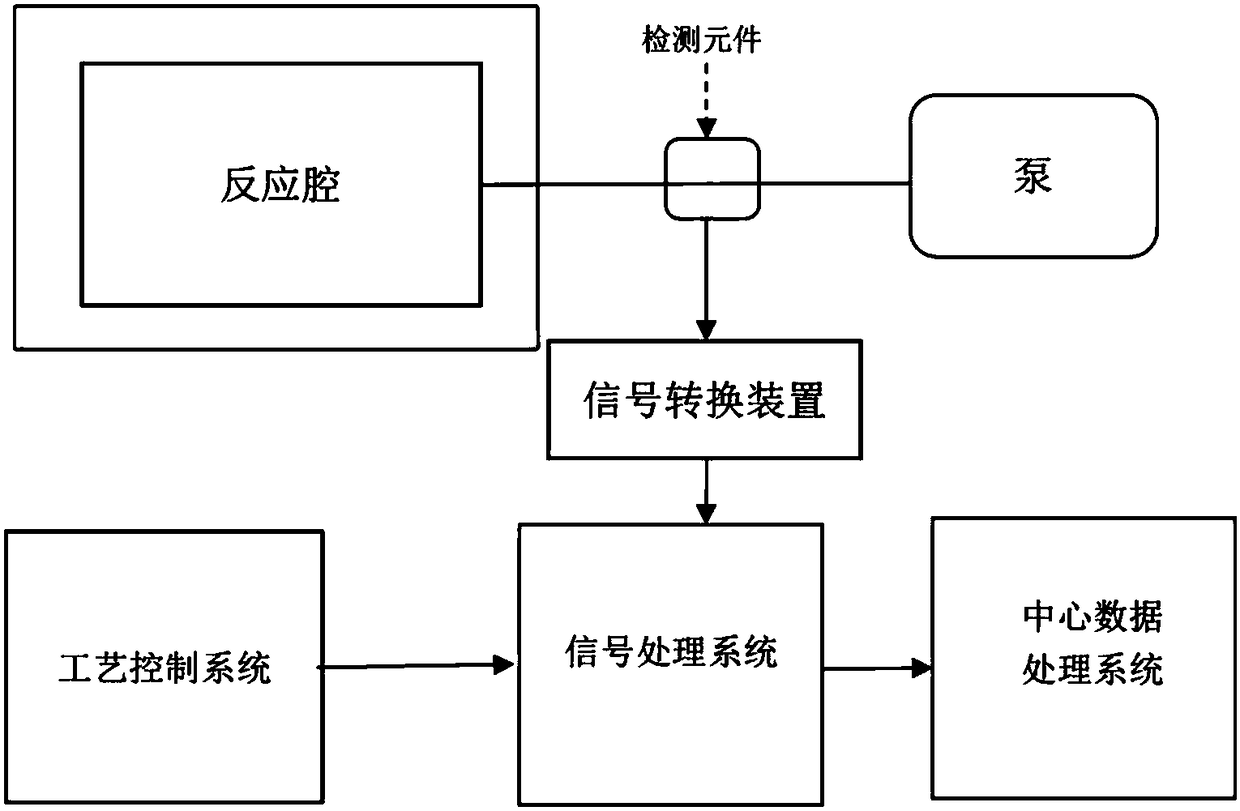

[0031] Such as figure 1 As shown, the monitoring system is provided with detection elements, signal conversion devices, signal processing systems, process control systems and central data processing systems; During the atomic layer deposition process, the vacuum pump is always in working condition, and the gas in the reaction chamber will always flow through the pump chamber tube.

[0032] In the process of mass production, the signal conversion device is a mass spectrometer, and the mass spectrometer will be connected to the cavity pump tube through the flange interface. When the relevant particles pass through, they will enter the detection element, enter the detection element in sequence according to the mass-to-charge ratio, and pass through the signal conversion device. The signal is converted into an electrical signal; it is drawn into a mass spectrogram through the signal processing system, and finally recorded in the central data processing system.

[0033] Under norm...

Embodiment 2

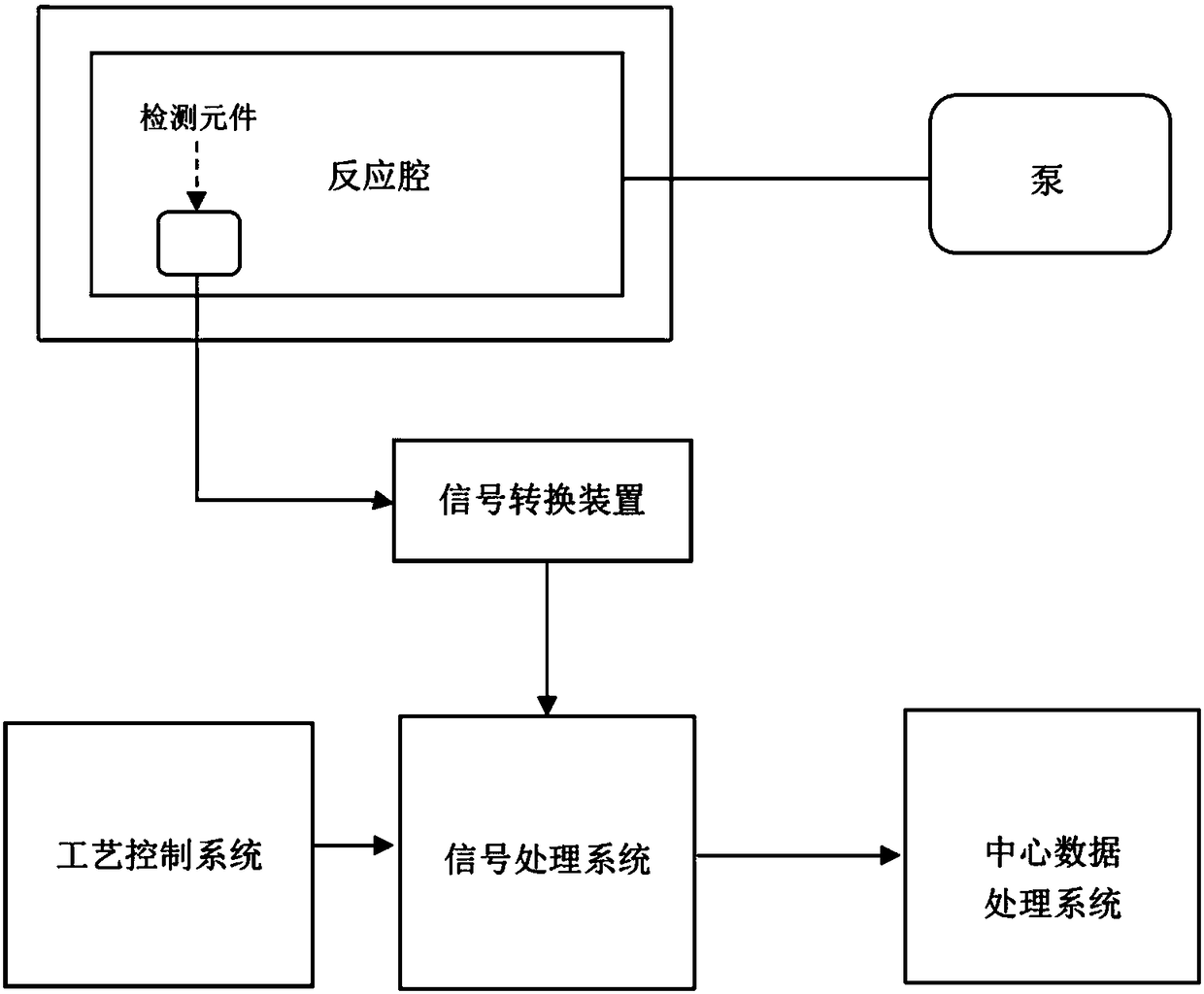

[0037] Such as figure 2 As shown, the monitoring system is provided with a detection element, a signal conversion device, a signal processing system, a process control system and a central data processing system; the detection element is arranged in the reaction chamber.

[0038] In the process of mass production, the signal conversion device uses ellipsometer to fix the light source, detection element and other auxiliary facilities inside the equipment. The light after the interference of the light source passes into the detection element, and the light is converted into an electrical signal by the signal conversion device ; and draw a film thickness change map through the signal processing system. Finally recorded in the central data processing system.

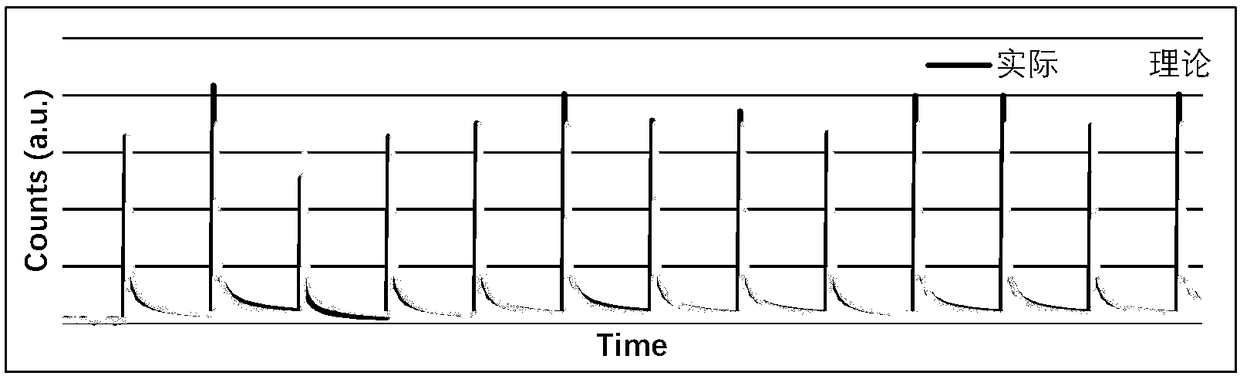

[0039] Under normal circumstances, the image drawn by the signal processing system will be fitted with the theoretical image formed by the process parameters provided by the process control system, such as Figure 6 ;

...

Embodiment 3

[0044]The difference between embodiment 3 and embodiments 1 and 2 is that the detection element is a piezoelectric material, and the signal conversion device is composed of an oscillating circuit, a frequency counter and a controller. The function of the signal conversion device is to convert the physical changes on the piezoelectric material It is an identifiable electrical signal; the piezoelectric material is set at the air flow of the atomic layer deposition equipment, the atomic layer is deposited on the piezoelectric material, the piezoelectric material produces a piezoelectric effect, and the piezoelectric material converts physical changes into electrical signals, and The electrical signal is transmitted to the signal processing system; the process control system transmits the real-time theoretical process state to the signal processing system, and the signal processing system matches the real-time process state with the theoretical process state, and monitors the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com