Base plate transfer system

A transmission system and substrate technology, applied in the direction of conveyor objects, furnaces, charge manipulation, etc., can solve the problem of serious friction of the substrate, and achieve the effects of avoiding particles, improving reliability, and extremely friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

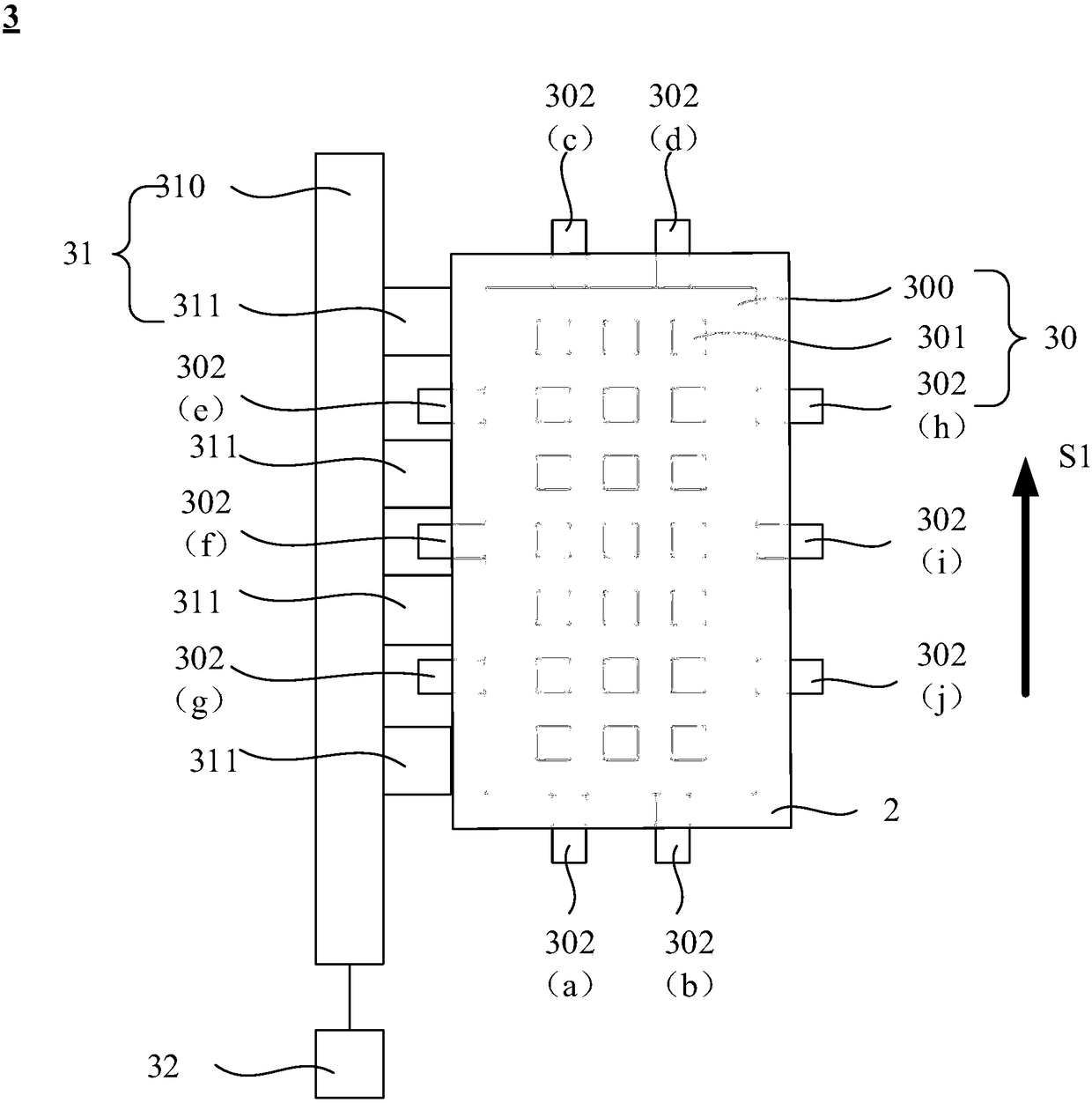

[0031] Please refer to figure 2 , which is a schematic structural diagram of a substrate transfer system according to Embodiment 1 of the present invention. Such as figure 2 As shown, in the embodiment of the present application, the substrate conveying system 3 is used to convey a substrate 2, and the substrate conveying system 3 specifically includes: a guide device 30, the guide device 30 is used to support the substrate 2 and the There is a gap between the guide device 30 and the substrate 2; the conveying device 31, the conveying device 31 is used to convey the substrate 2, and the conveying device 31 fixes the substrate 2 by suction and conveys it.

[0032] Specifically, the guide device 30 is capable of ejecting gas, and a gap exists between the guide device 30 and the substrate 2 through the ejected gas. Preferably, the gap (that is, the distance difference between the substrate 2 and the guide device 30 ) is 0.1 mm to 1 mm, for example, the gap is 0.2 mm, 0.3 mm, ...

Embodiment 2

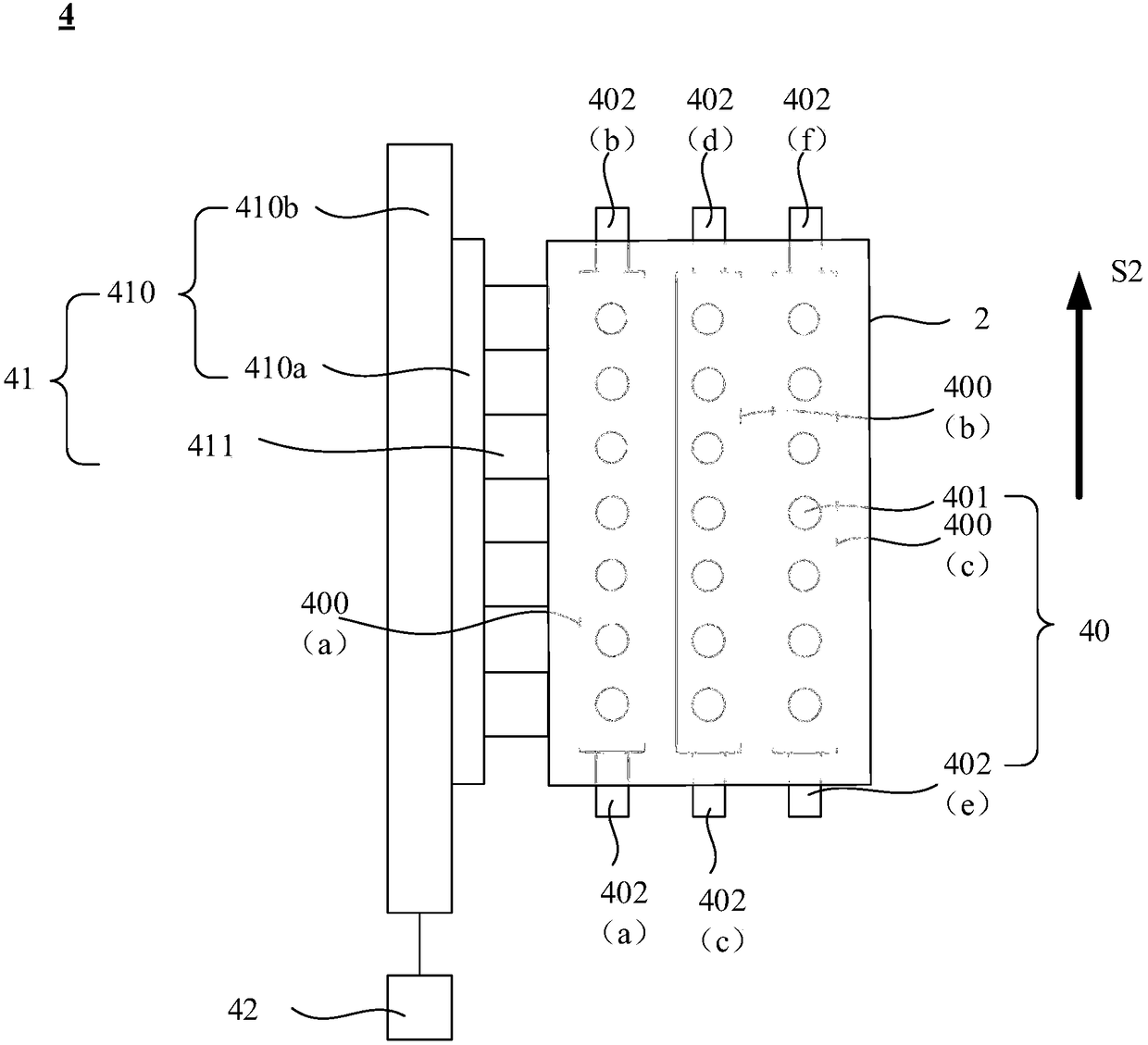

[0044] Please refer to image 3 , which is a schematic structural diagram of a substrate conveying system according to Embodiment 2 of the present invention. Such as image 3 As shown, in the embodiment of the present application, the substrate conveying system 4 is used to convey a substrate 2, and the substrate conveying system 4 specifically includes: a guide device 40, the guide device 40 is used to support the substrate 2 and the There is a gap between the guide device 40 and the substrate 2; the transfer device 41, the transfer device 41 is used to transfer the substrate 2, and the transfer device 41 fixes the substrate 2 by suction and transfers it.

[0045] Specifically, the guide device 40 can eject gas, and a gap exists between the guide device 40 and the substrate 2 through the ejected gas. Preferably, the gap (that is, the distance difference between the substrate 2 and the guide device 40) is 0.1 mm to 1 mm, for example, the gap is 0.2 mm, 0.3 mm, 0.5 mm, 0.65 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com