Multifunctional reciprocating type cut-to-size saw

A reciprocating, panel saw technology, applied in the direction of circular saws, sawing components, sawing equipment, etc., can solve the problems of scratched boards, table friction, inconvenient disassembly and assembly operations, etc., to achieve high processing efficiency and protect the contact surface , the effect of small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

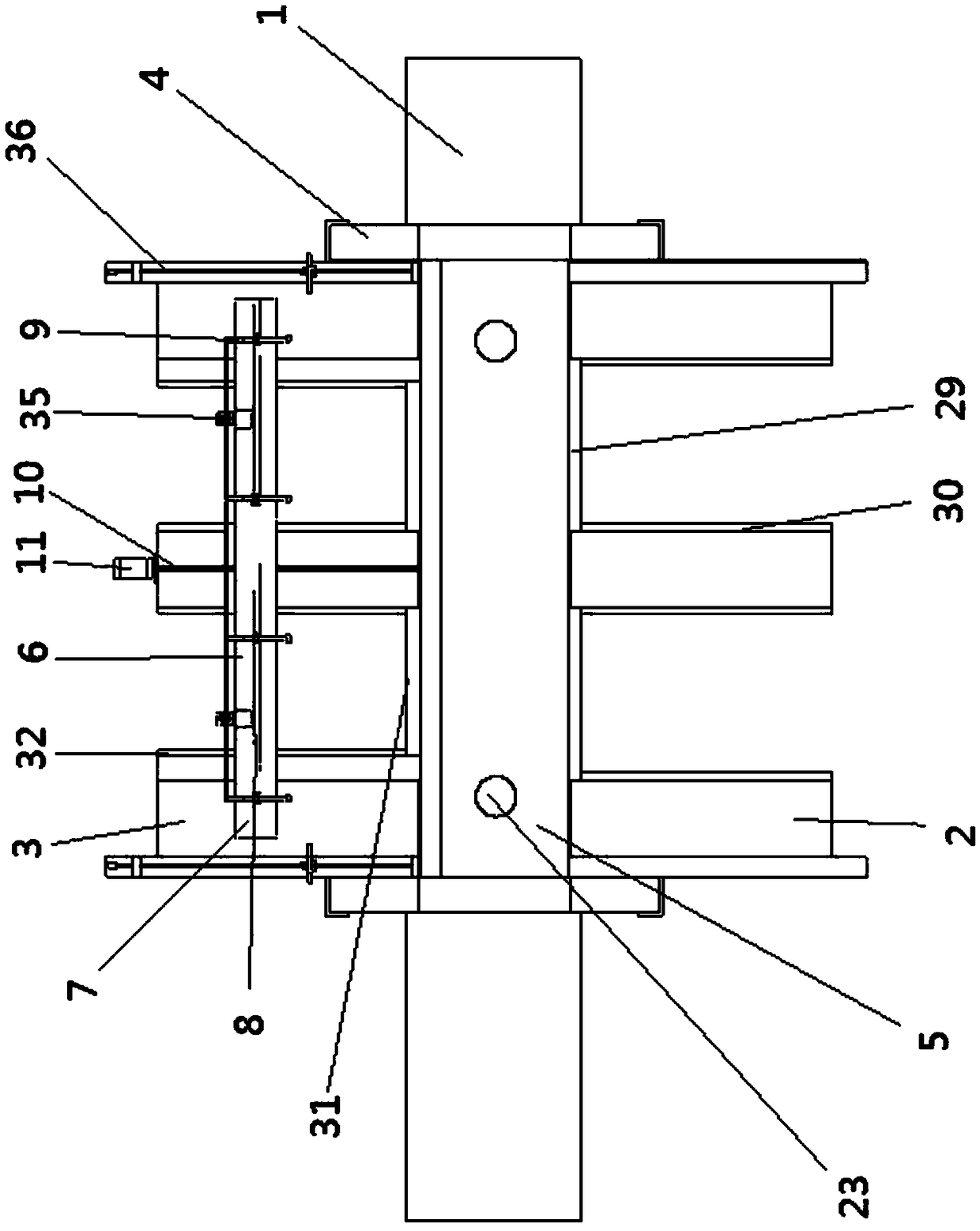

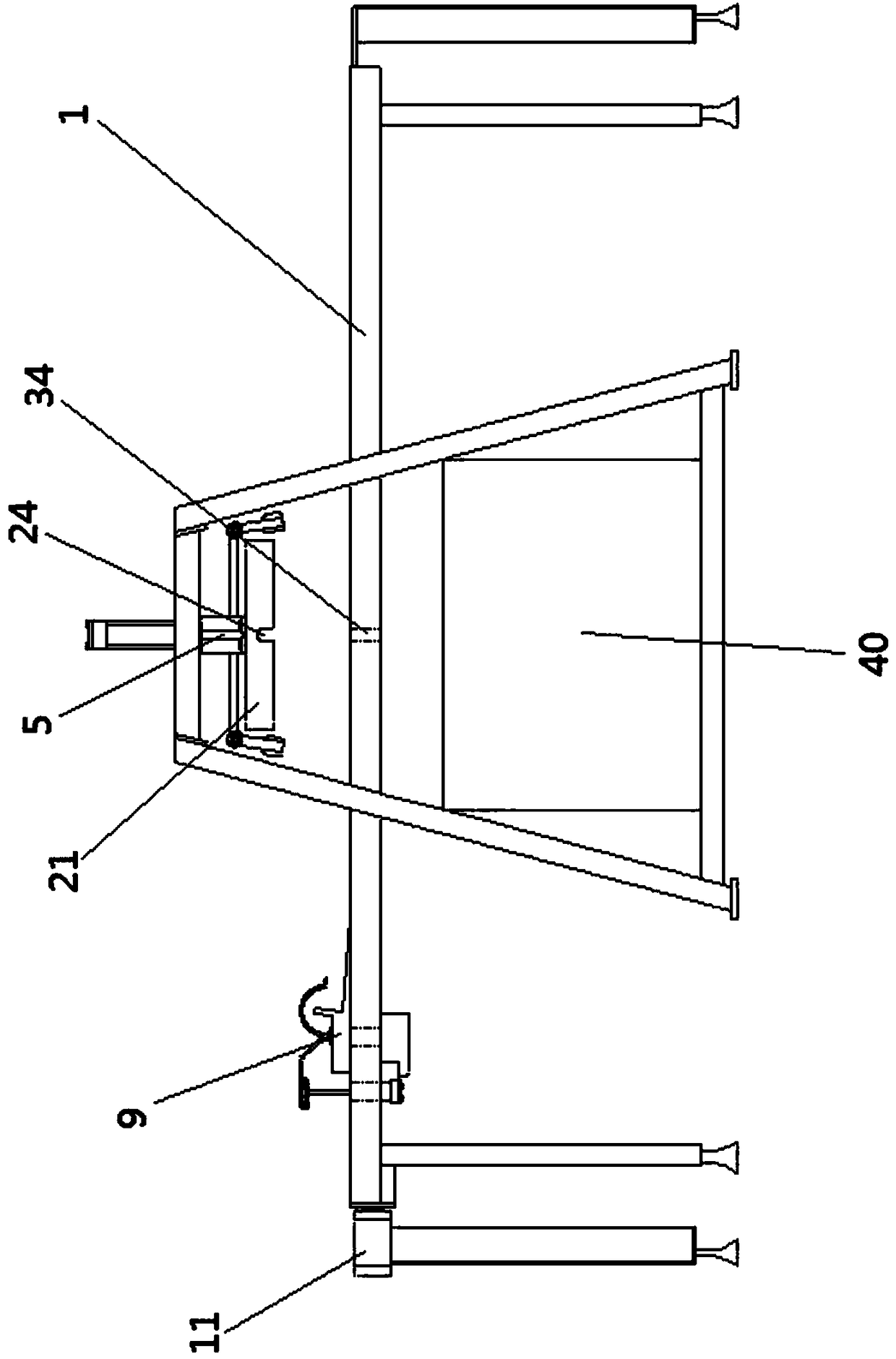

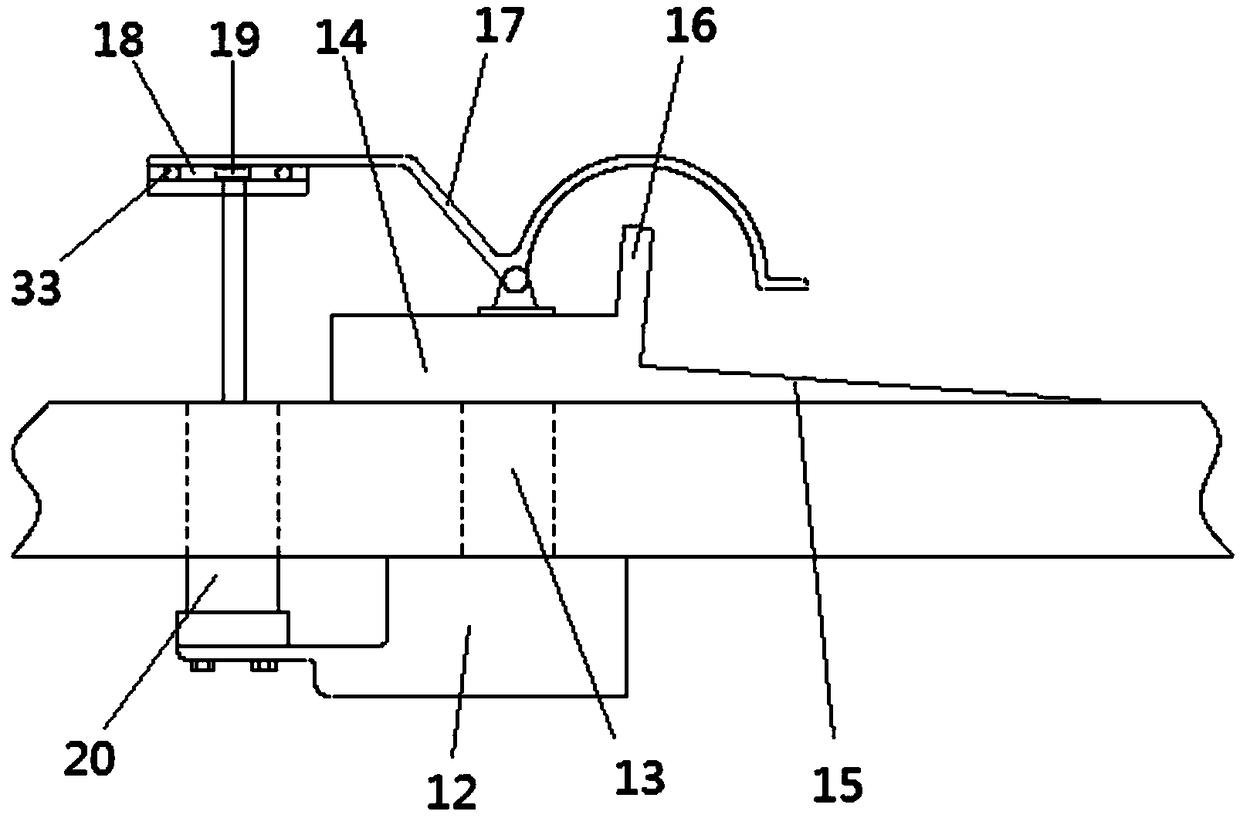

[0026] Embodiment: a kind of multifunctional reciprocating panel saw, structure such as Figures 1 to 6 As shown, it includes a fuselage body 1, and one side of the fuselage body 1 is provided with three equally spaced front workbenches 2, and the other side of the fuselage body 1 is provided with three equidistantly distributed rear workbenches 3, and the fuselage body 1 A pressing device 5 is erected above a pair of crossbeams 4, and a plate fixing device 6 is arranged across the three rear workbenches 3. The plate fixing device 6 includes a cross baffle 7, and a slide rail 8 is arranged on the cross baffle 7. , the slide rail 8 is provided with several plate fixing device monomers 9 equally spaced, and the plate fixing device 6 is connected with a stepping motor 11 through a screw rod 10; the plate fixing device monomer 9 includes a lower base 12, and the lower base 12 is connected with upper base 14 through cylinder 13, and described upper base 14 comprises inclined platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com