Scale removal device for profile steel

A technology of descaling device and section steel, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of unsatisfactory rolling kilometers of slot holes in profile rolling mills and no descaling device, etc., and achieves simple structure and reduced Grinding effect, the effect of increasing rolling kilometers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

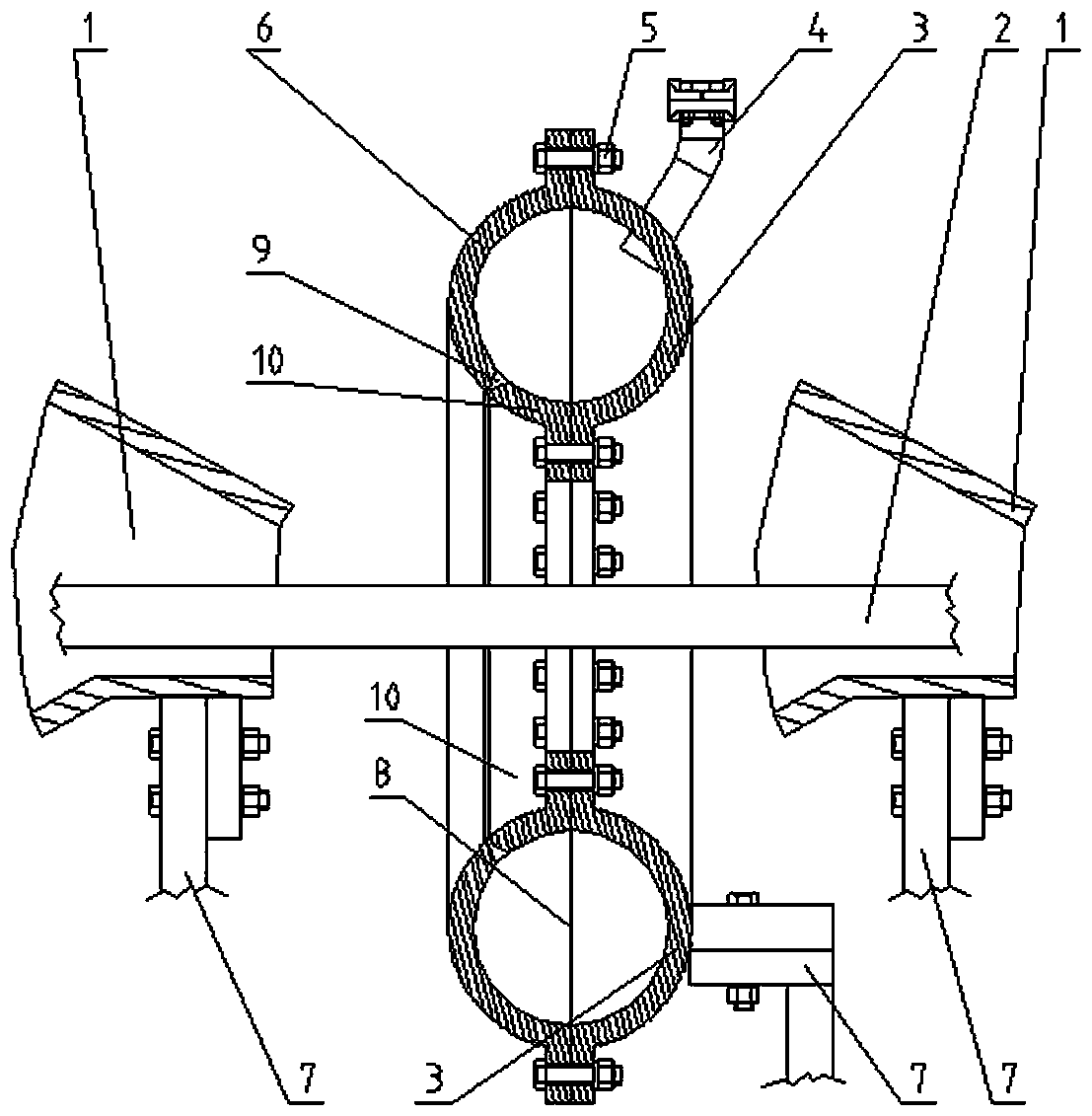

[0008] like figure 1 As shown, the shaped steel descaling device of the present invention is mainly composed of a ring type header, a guide box 1, a rolling piece 2, a connecting frame 7, and a water inlet pipe 4. The ring type header is mainly composed of a rear cover 3, a front outer cover 6, a front inner cover 10, bolts 5, and a gasket 8. Between the front outer cover 6 and the front inner cover 10, there is a rightward-inclining injection port 9 of annular structure. Gasket 8 is installed in the plane pressed by bolt 5 between back cover 3 and front outer cover 6 , front inner cover 10 . The water inlet pipe 4 is installed through the back cover 3 .

[0009] like figure 1 As shown, the guide box 1 mainly ensures that the rolling piece 2 passes through the middle position of the ring-type header smoothly. When the rolling piece 2 is tightened by the upstream and downstream rolling mills during the rolling process, the ring-type steel descaling device of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com