Self-tapping skull hollow drill and using method thereof

A hollow drill and skull technology, applied in the field of medical devices, can solve the problems of difficult to control the drilling depth, poor hand feel, and difficult to repair the skull defect by itself, and achieve the requirements of avoiding complex structures and high-strength special steel, avoiding cross-infection, structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

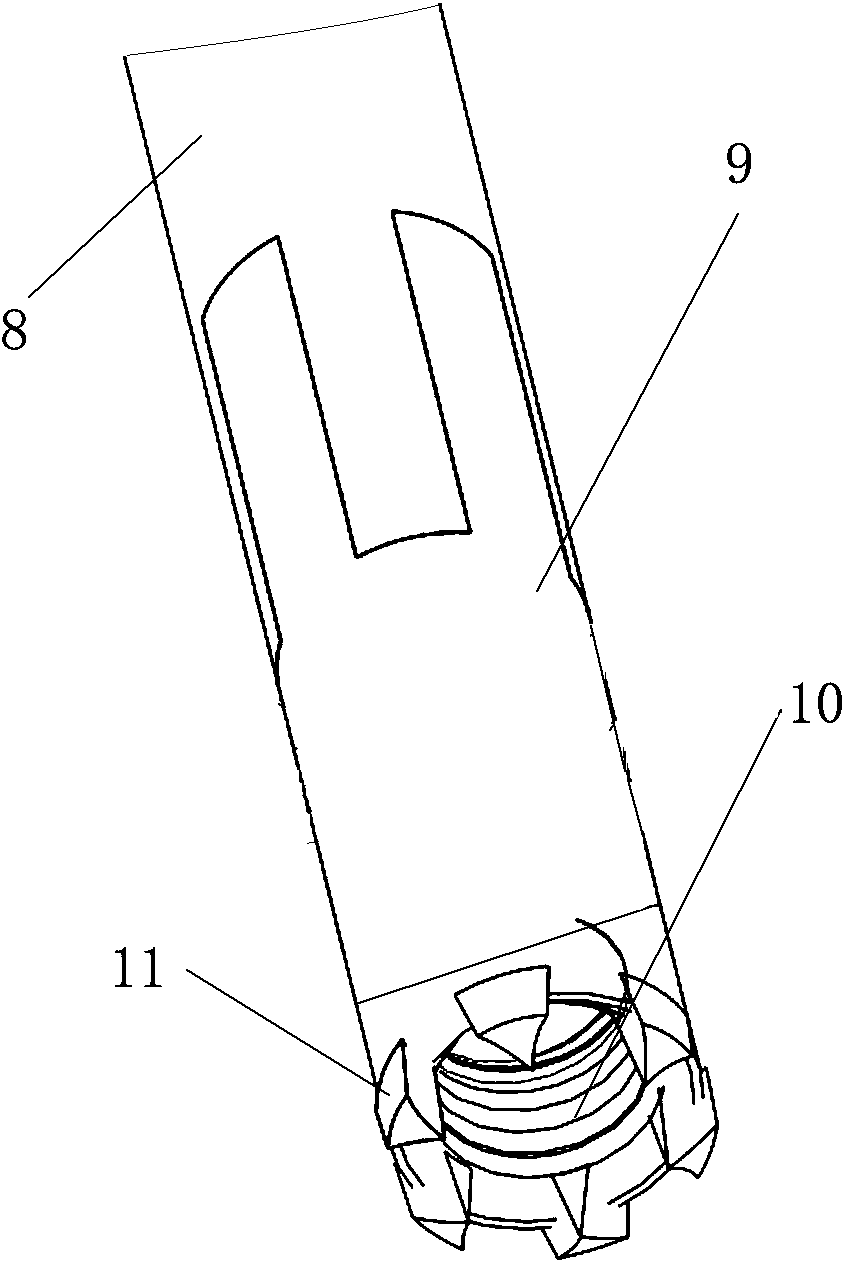

[0033] See attached Figure 1-3 It is an embodiment of the present invention, disclosing a self-tapping skull hollow drill, including a sleeve 7, the upper part of the sleeve 7 is provided with a pressure rod 2 capable of adjusting the height, and the lower part is provided with a drill rod 8 , the two sides are respectively provided with a handle 5 and a hand rocker 6, and one end of the hand rocker 6 realizes mechanical transmission with the drill rod 8 inside the sleeve 7; the end of the drill rod 8 is clamped with a drill bit 9, The drill bit 9 can be freely replaced at the end of the drill rod. The drill bit 9 is hollow inside and has a wall thickness of 1.5-2mm. A discontinuous inner ring surface 14 is formed on the inner side of the knife 11, and a discontinuous outer ring surface 13 is formed on the outside of each drill bit 11. The outer diameter of the outer ring surface 13 is greater than the outer diameter of the drill bit 9, and each drill bit bottom surface 12 fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com