Manufacturing method of copper substrate for new energy electric vehicle BMS protection

A technology of electric vehicles and production methods, which is applied in chemical/electrolytic methods to remove conductive materials, manufacture printed circuits, and assemble printed circuits with electrical components. Accuracy, avoiding offset movement, and ensuring the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

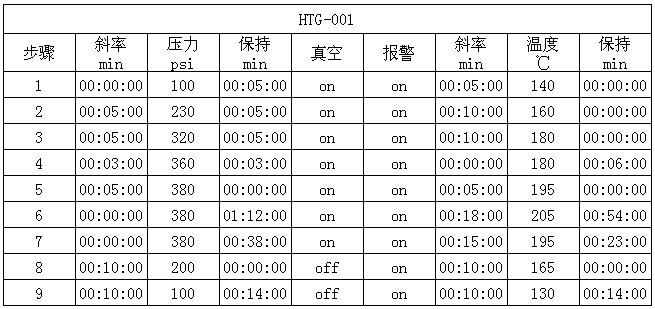

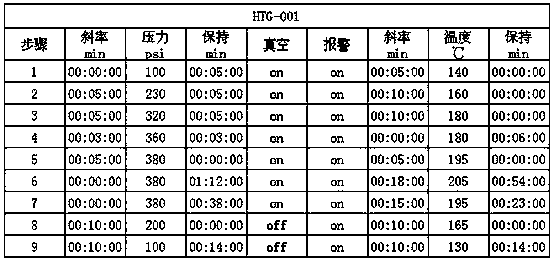

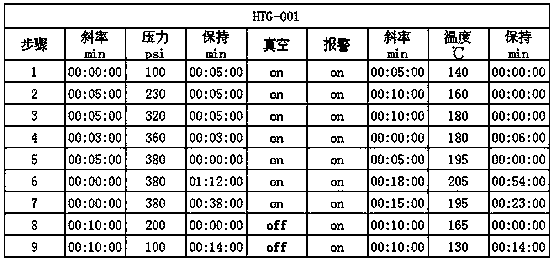

[0039] The specific implementation method of the present invention is as follows: the double-sided copper-clad FR4 substrate is made into a core board, and copper bars are embedded in the corresponding slots on the core board, and then PP is pasted on the upper and lower surfaces of the core board (PP is 2116RC55%, thickness 0.129mm), and then attach a FR4 single-sided board with one side free of copper and one side copper-clad on the PP, and make one side of the bare board contact with PP, and then stick a release film and a silicone board on the copper-clad side of the FR4 single-sided board , and then use the above-mentioned HT-G001 pressing program for pressing.

[0040] In summary, the present invention solves the problem that the existing PCB process cannot produce the BMS protective copper substrate of new energy electric vehicles. It presses the BMS protective copper substrate by pasting high-temperature tape and adjusting the parameters of the pressing program. As a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com