Power takeoff relay control system with clutch and use method thereof

A relay-controlled technology with a clutch, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve problems such as the inability to achieve free shifting, and achieve the effect of good prompting effect, high safety, and avoiding operation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

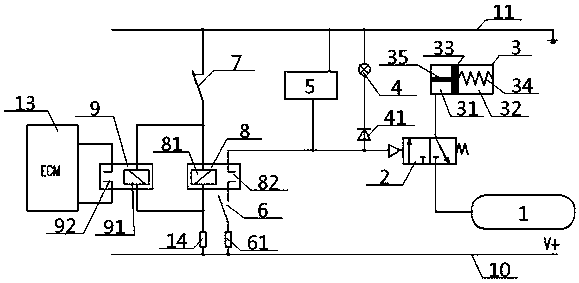

[0039] A relay control system for a power take-off with a clutch, comprising a clutch, a power take-off, a power take-off solenoid valve 2, an air storage tank 1, a clutch switch 7, a power take-off switch 6 and an internal relay 8, the air outlet of the air storage tank 1 It communicates with the intake port of the power take-off solenoid valve 2. The clutch cylinder 3 in the clutch includes an outer chamber 31, an inner chamber 32 and a clutch piston 33 between the two. One side of the clutch piston 33 is clutched. The spring 34 is connected with the right side wall of the inner chamber 32, the other side of the clutch piston 33 is connected with one end of the connecting shaft 35, the other end of the connecting shaft 35 extends outside the outer chamber 31, and is connected with the power take-off The input terminal of the power take-off solenoid valve 2 is connected for driving; the outer chamber 31 is connected to the gas tank 1 through the power take-off solenoid valve 2...

Embodiment 2

[0042] Basic content is the same as embodiment 1, the difference is:

[0043] The power take-off switch 6 is electrically connected with the power line 10 through the insurance 61, and the power line 10 is connected with the inner coil 81 through the load resistance 14.

Embodiment 3

[0045] Basic content is the same as embodiment 1, the difference is:

[0046] The power take-off relay control system also includes an external relay 9 and ECM13, the two ends of the ECM13 are connected to the two ends of the external contact 92 of the external relay 9, and one end of the external coil 91 in the external relay 9 is connected to the clutch switch 7, The junction of the inner coil 81 is connected, and the other end of the outer coil 91 is connected with the junction of the inner coil 81 and the power line 10 .

[0047] When the clutch switch 7 is closed, the external relay 9 is energized, and the external coil 91 and the external contact 92 are in contact with each other to send the signal that the clutch switch 7 is closed to the ECM13; when the clutch switch 7 is opened, the external relay 9 loses power, The outer coil 91 and the outer contact 92 are separated, and the ECM 13 cannot receive the signal from the outer relay 9, thereby judging that the clutch swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com