Power take-off ECU control system with clutch and using method thereof

A control system with clutch technology, applied in the direction of clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve problems such as the inability to realize free shifting, achieve good prompting effects, avoid operating errors, and have high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

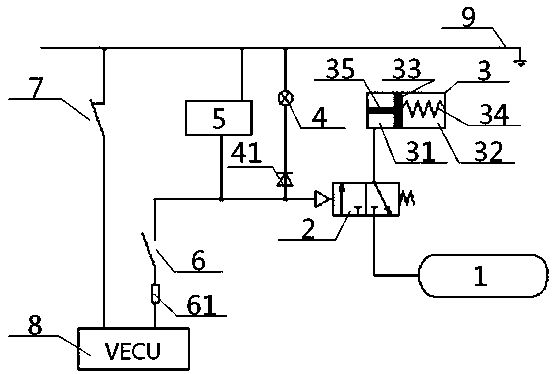

[0037] see figure 1 , a power take-off ECU control system with a clutch, including VECU8, clutch, clutch switch 7, power take-off switch 6, power take-off, power take-off solenoid valve 2 and air storage tank 1, the air outlet of the air storage tank 1 and The intake ports of the force-taking electromagnetic valve 2 are communicated, and the clutch cylinder 3 in the clutch includes an outer chamber 31, an inner chamber 32 and a clutch piston 33 between the two, and one side of the clutch piston 33 is connected by a clutch spring 34 is connected with the right side wall of the inner chamber 32, the other side of the clutch piston 33 is connected with one end of the connecting shaft 35, the other end of the connecting shaft 35 extends outside the outer chamber 31, and is connected with the power take-off The input end is connected to drive; the outer chamber 31 is connected to the air storage tank 1 through the power take-off solenoid valve 2, and the control end of the power ta...

Embodiment 2

[0040] Basic content is the same as embodiment 1, the difference is:

[0041] The junction between the power take-off switch 6 and the control end of the power take-off solenoid valve 2 is connected to the grounding wire 9 via the multifunctional buzzer 5 and the indicator light 4 connected in parallel.

[0042] When the power is taken normally, the multifunctional buzzer 5 and the indicator light 4 are energized, the multifunctional buzzer 5 makes a sound, and the indicator light 4 lights up to remind the operator that the power is being taken off; When shifting gears, the multi-function buzzer 5 and the indicator light 4 lose power, the multi-function buzzer 5 does not sound, and the indicator light 4 does not light.

Embodiment 3

[0044] Basic content is the same as embodiment 2, the difference is:

[0045] The junction between the power take-off switch 6 and the control end of the power take-off solenoid valve 2 is connected to the anode of a diode 41 , and the cathode of the diode 41 is connected to the ground wire 9 via the indicator light 4 .

[0046] During normal power take-off, after the power take-off switch 6 and the clutch switch 7 are closed, only unidirectional current flows through the diode 41 to prevent the power take-off from malfunctioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com