Wind power plant booster station, and 35kV current collection line equipment prevention test period optimization method and system

A technology for preventive testing and collecting lines, applied in forecasting, instrumentation, data processing applications, etc., can solve problems such as ineffectiveness in judging equipment operation risks, inability to periodically optimize preventive testing, etc. The effect of preventing equipment damage and ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] This embodiment is the wind farm equipment involved in the third phase of Damao Wind Farm, Dashantai Wind Farm, Youyu Wind Farm, and Pinglu Yungaisi Wind Farm.

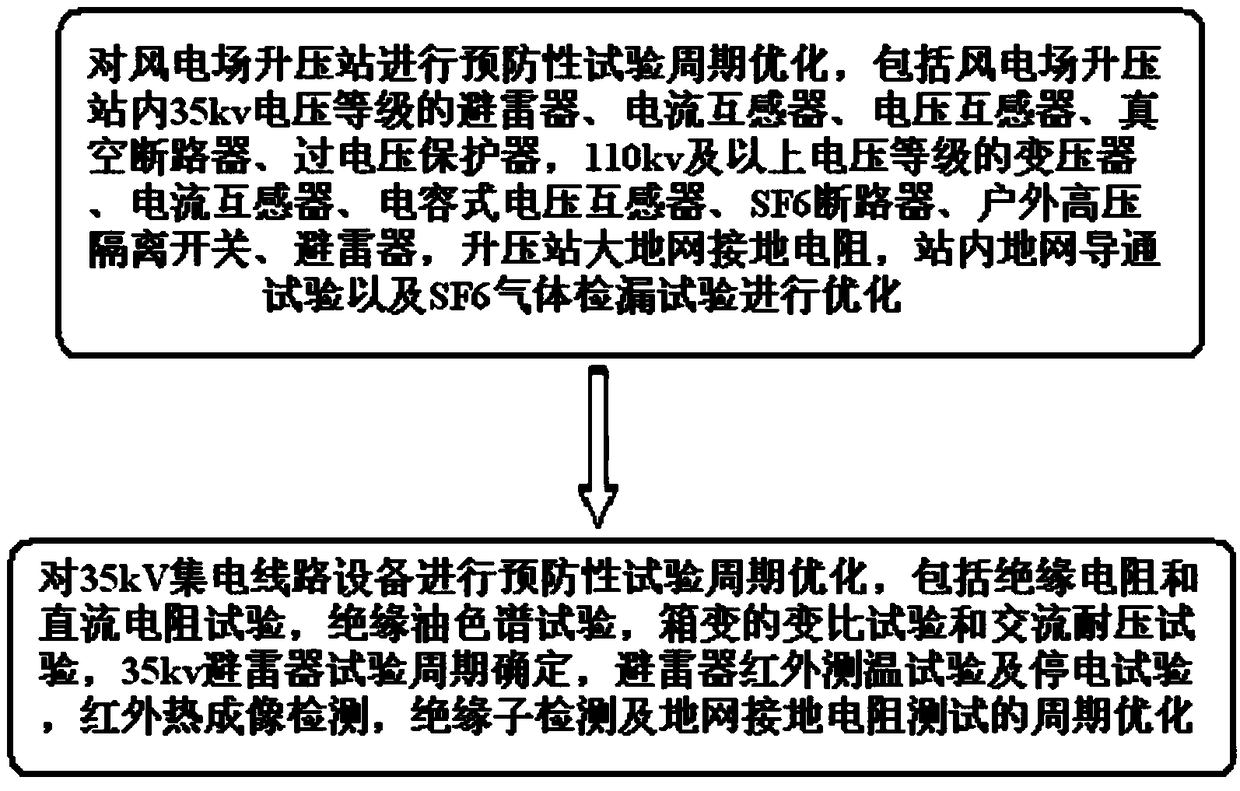

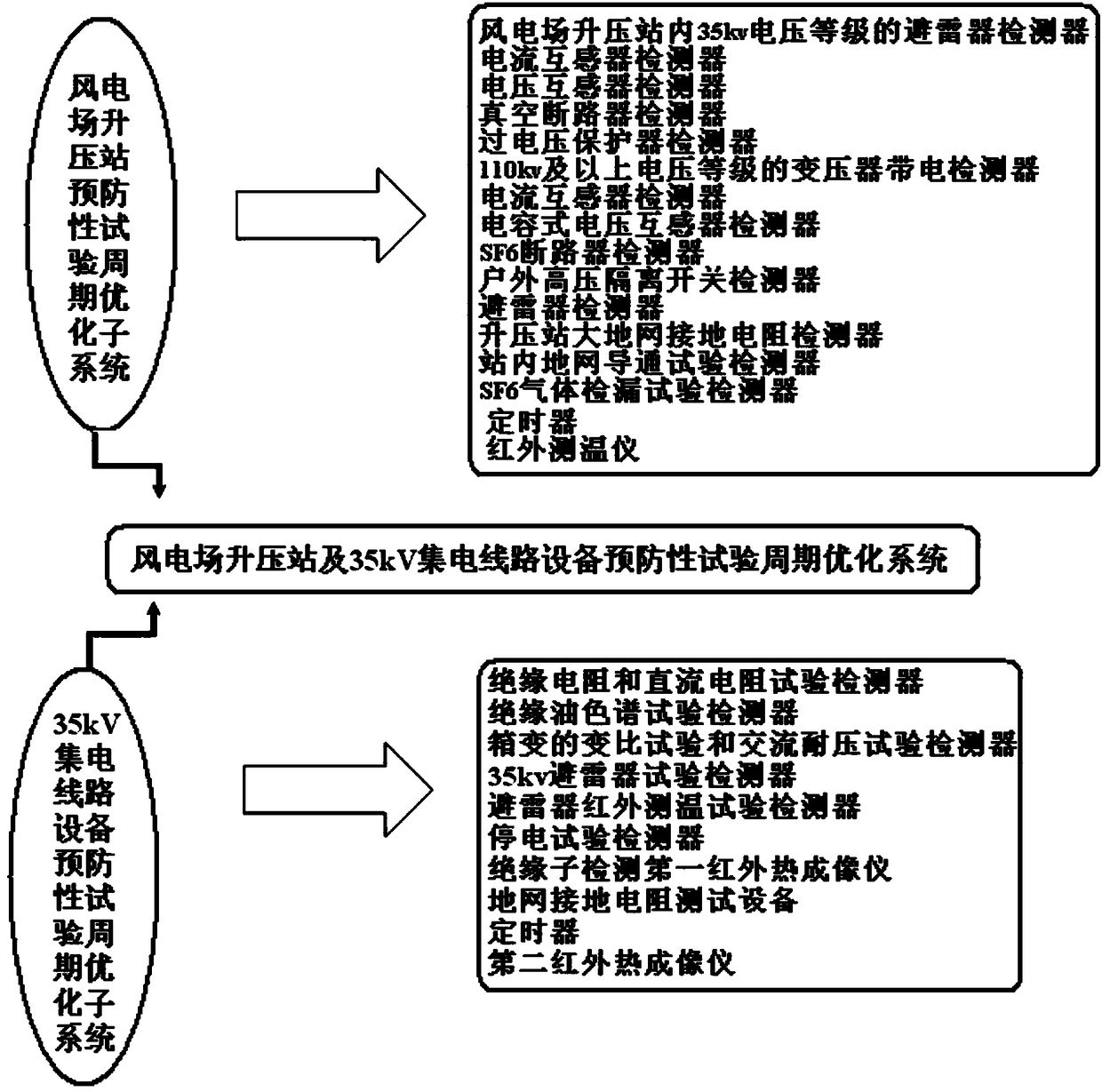

[0043] See attached figure 1 , for the booster station pre-test maintenance, the purpose of the preventive test optimization of the wind farm booster station is to timely discover hidden dangers in the operating equipment of the 110kv and above voltage level booster station of the company's wind farm, prevent equipment damage, and ensure the safe operation of the equipment, according to According to the operating status of the 110kv and above voltage level step-up station of the Tianrun North China Branch, combined with the condition-based maintenance requirements, the following preventive test optimization measures are formulated. The optimization basis for the preventive test of the wind farm booster station is "North China Power Grid Co., Ltd. Power Equipment Handover and Preventive Test Regulations" 2008 ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com