Converter primary dedusting OG system parameter computer aided design method

A computer-aided and system parameter technology, applied in computer-aided design, calculation, design optimization/simulation, etc., can solve cumbersome and unresolved problems in the initial design process, improve efficiency, reduce computational complexity, and enhance practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

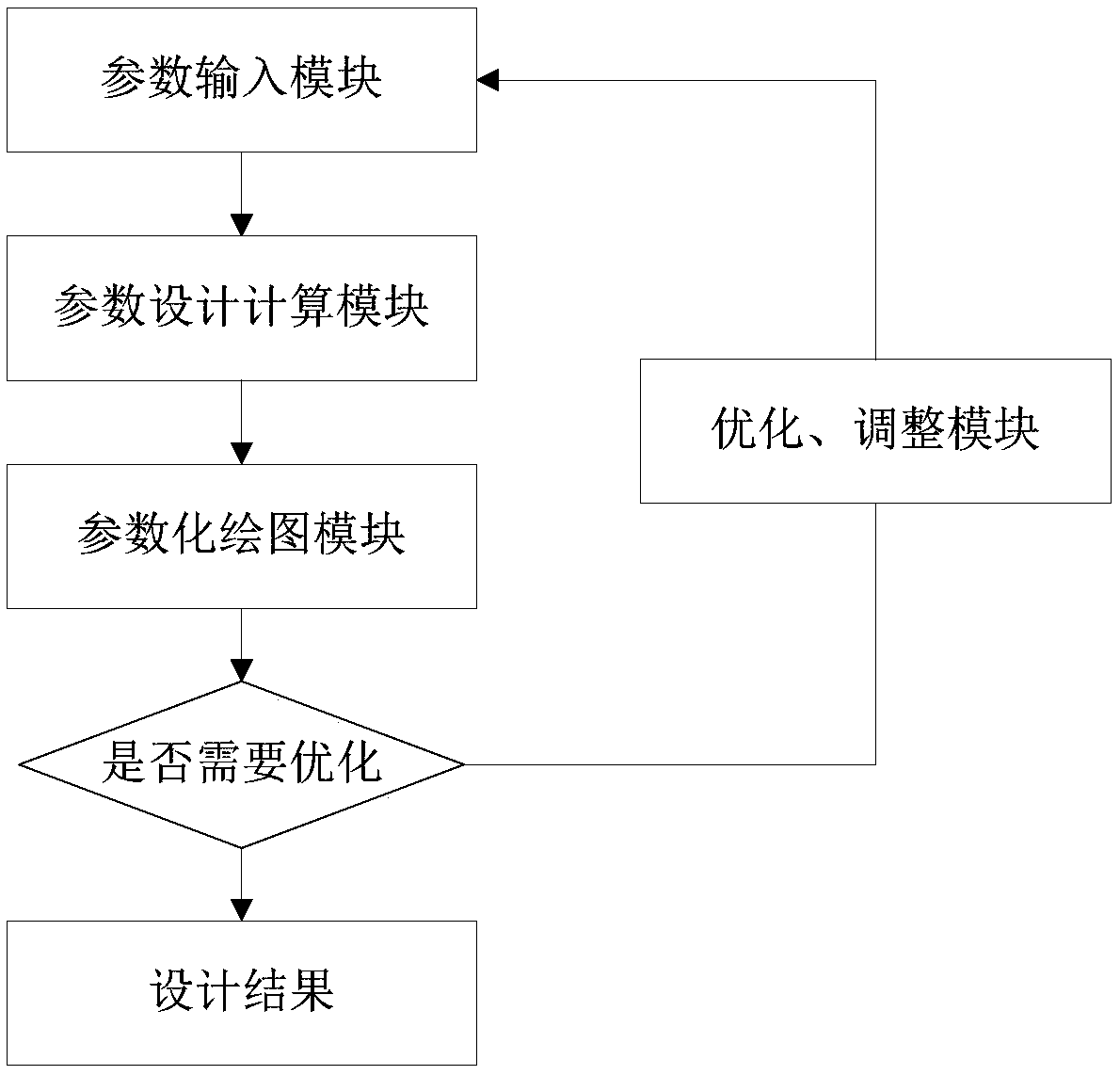

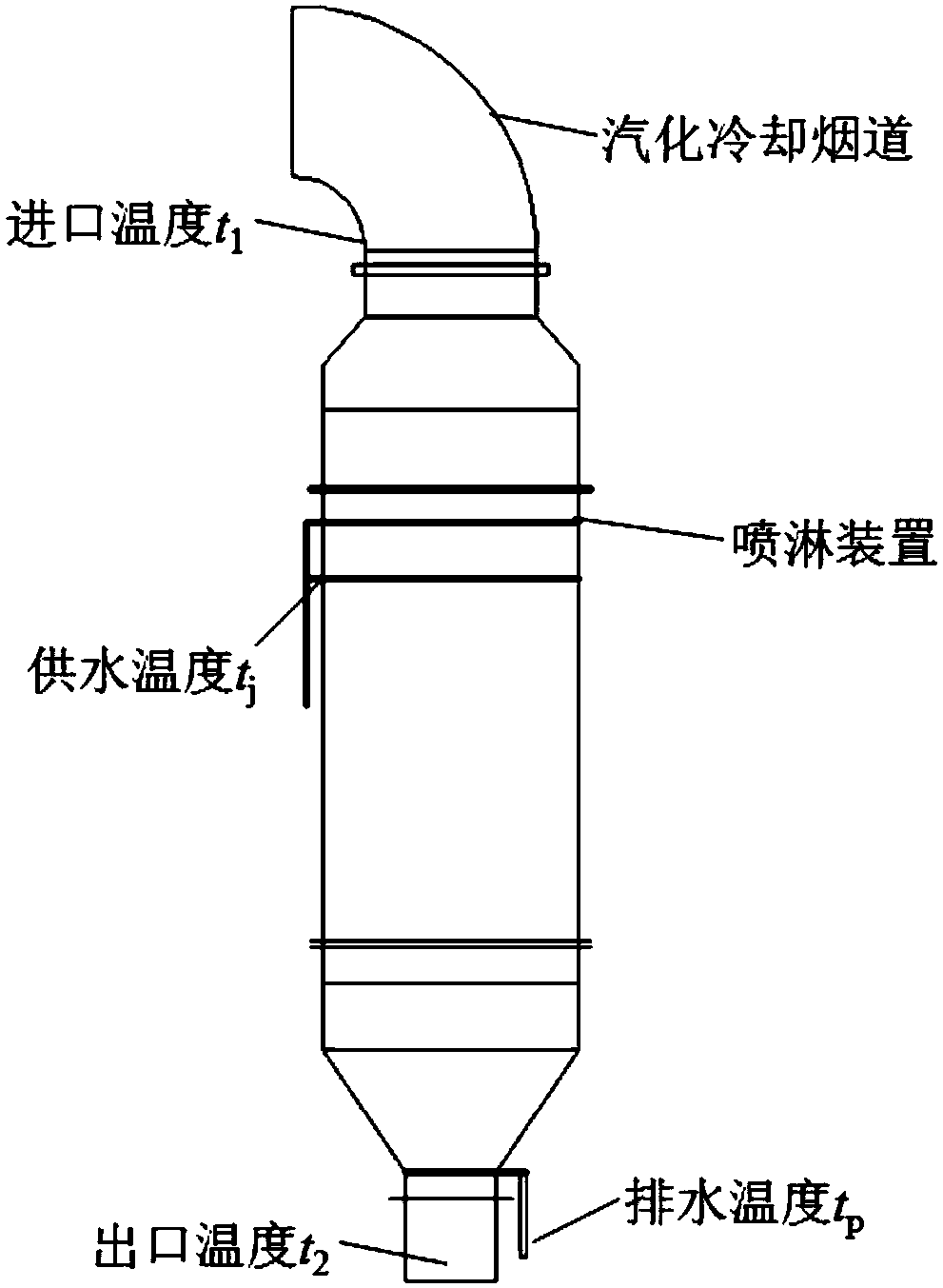

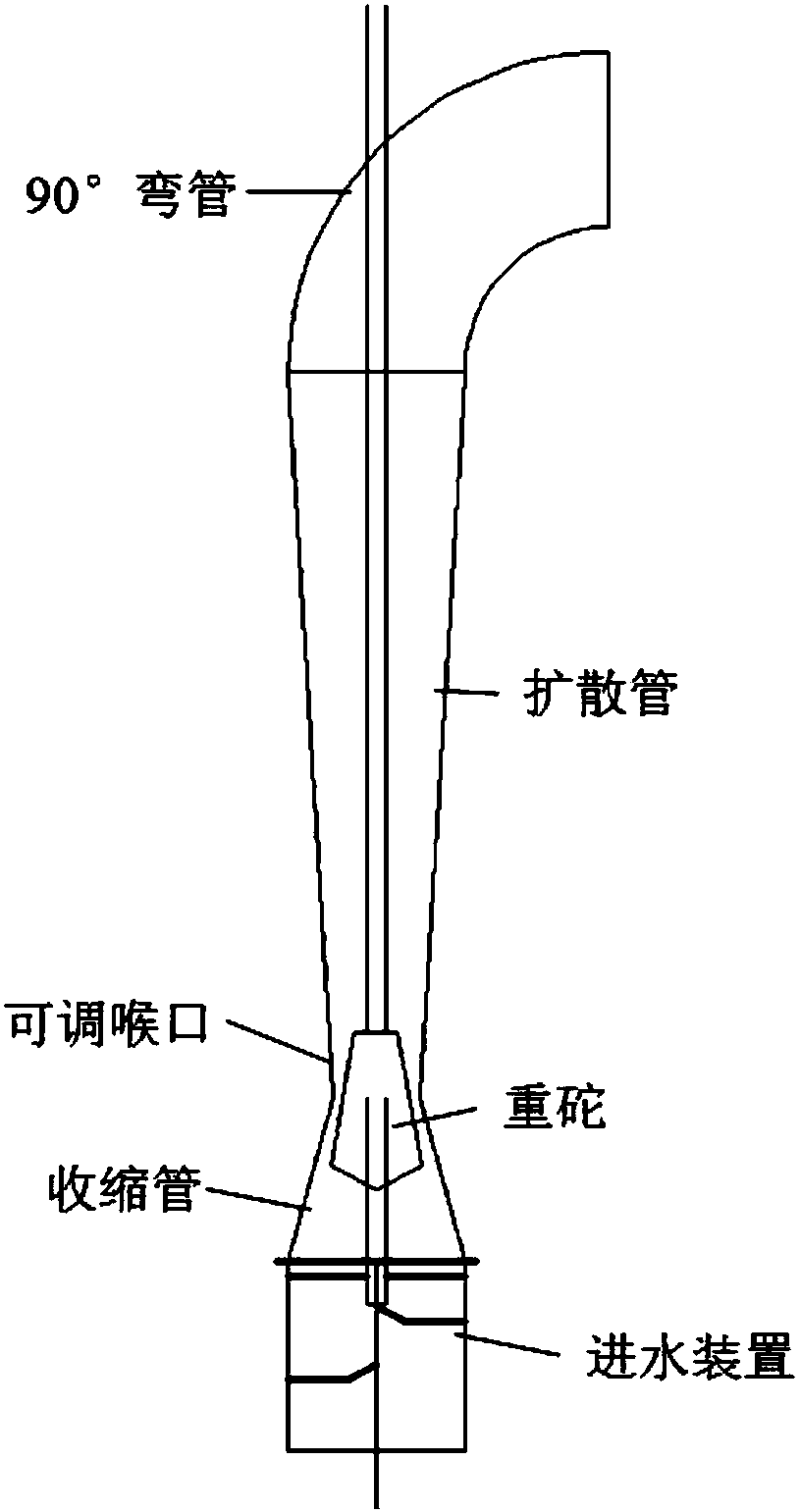

[0058] see figure 1 , a computer-aided design method for the parameters of the primary converter dust removal OG system in this embodiment is mainly designed for the two core equipment of the converter primary dust removal OG system - the high-efficiency scrubber and the annular venturi tube, the high-efficiency scrubber and the The key structure of the annular venturi see figure 2 with image 3 , this embodiment realizes the design calculation and parametric drawing of the high-efficiency scrubber and the annular venturi, and optimizes and adjusts it according to the design results. This embodiment mainly includes the following processes:

[0059] First, according to the structural and operating characteristics of the high-efficiency scrubber and the annular venturi tube, combined with long-term data analysis and experience summary, determine the design parameters of the high-efficiency scrubber and the annular venturi tube, the operating parameters of the OG system, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com