Quick-drying warm-keeping velvet fabric

A velvet and fabric technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of poor moisture conductivity and quick drying, single surface color pattern, etc., to improve variety diversity, wide usability, excellent warmth retention The effect of sex and moisture-wicking and quick-drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

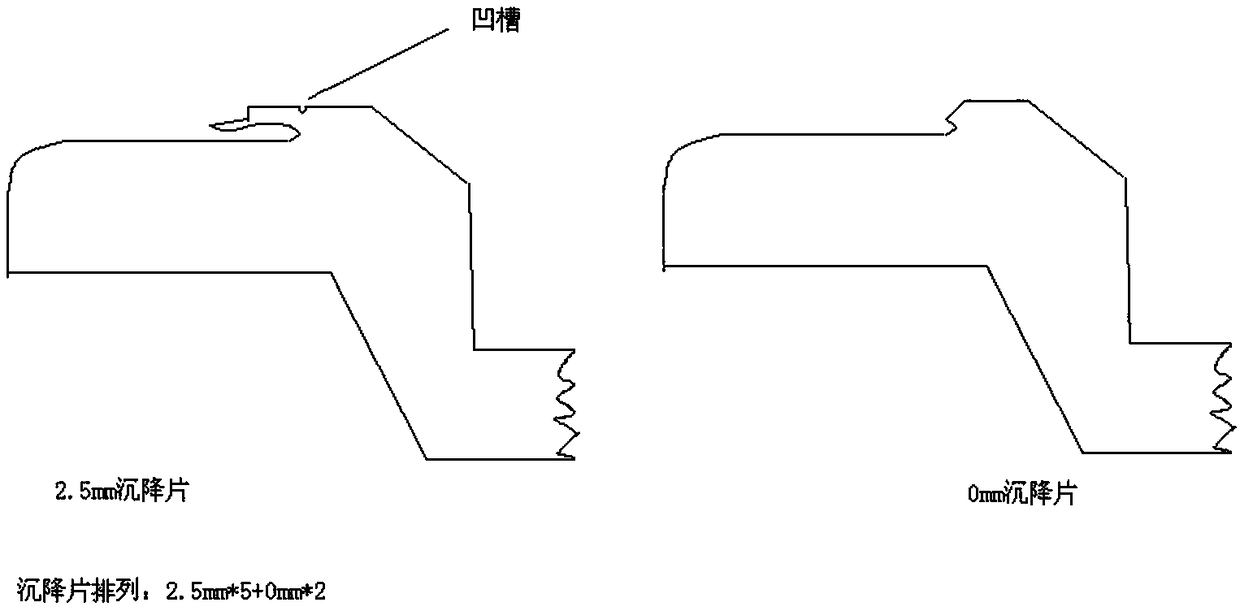

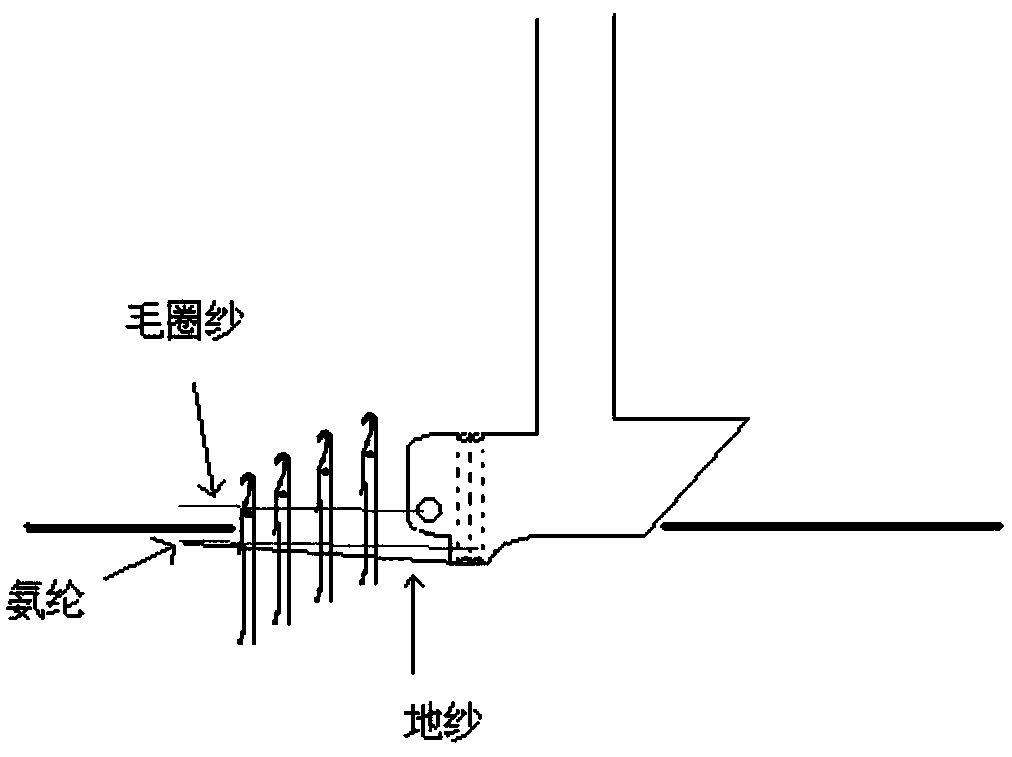

[0023] The ground yarn (40S / 1 polyester / tencel blended spun yarn), 40D spandex and loop yarn (100D cross-section polyester) are interwoven to form the surface layer, in which the ground yarn and spandex form a plating structure, and the ground yarn is on the surface On the front of the layer, spandex is inside the surface layer; special sinkers (0mm sinker and 2.5mm sinker) are arranged on the turn-up terry machine, so that part of the terry yarn (100D cross-section polyester) is exposed on the surface layer , can form different patterns on the surface layer, and finally make a quick-drying warm velvet fabric.

[0024] In this embodiment, a special sinker combination (0mm sinker and 2.5mm sinker) is configured when preparing the quick-drying warm velvet fabric. The structure diagram is shown in 1, and the working principle is as follows:

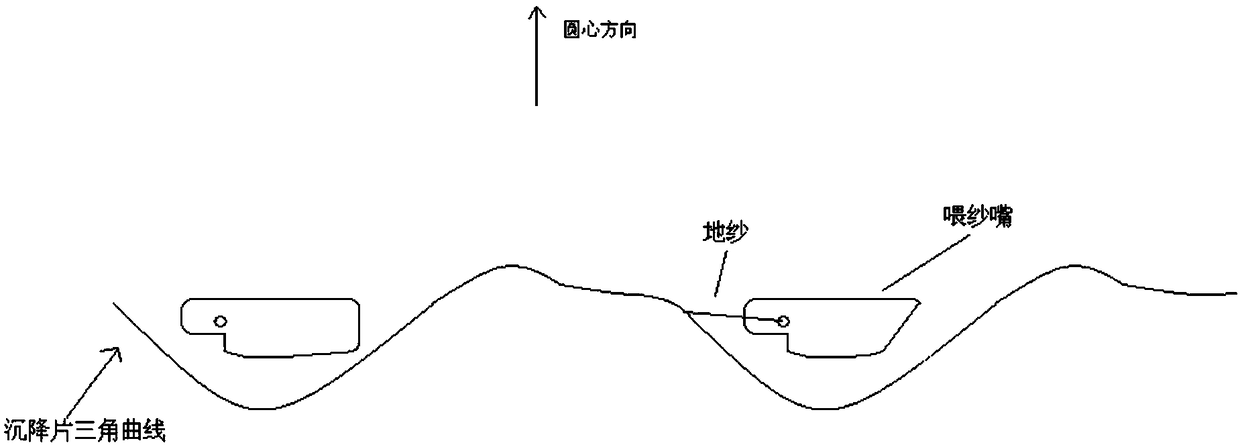

[0025] The relative positions of the yarn feeder and the sinker when preparing fabrics are as follows: figure 2 As shown, at this time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com