Pasty material conveying device and pasty material conveying system

A technology for conveying devices and materials, which is applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as high cost and complex structure, and achieve the effect of semi-automatic quantitative transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

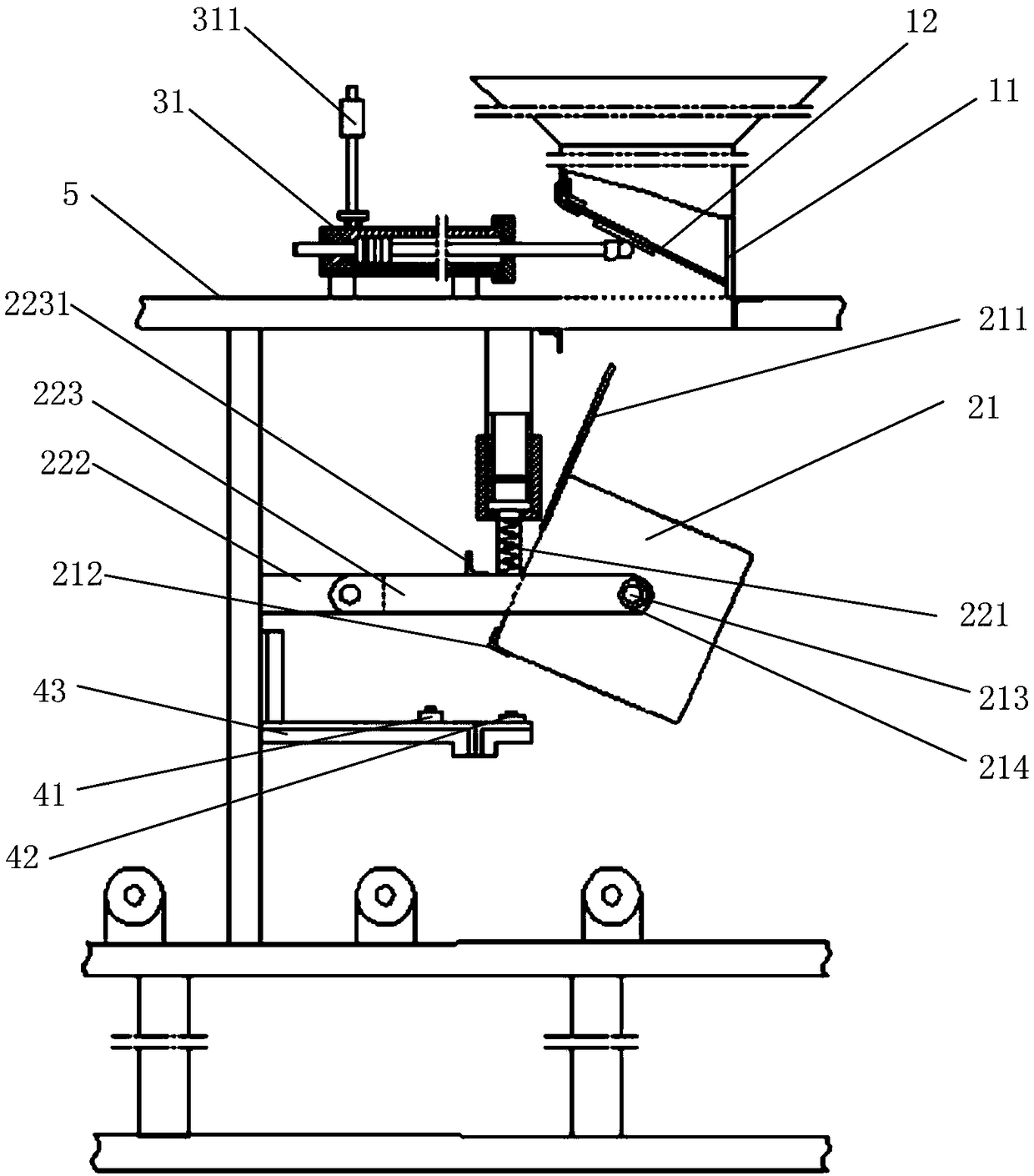

[0048] refer to figure 1 -3. The embodiment of the present invention provides a slurry material conveying device, including: a frame 5, a feeding unit, a transfer unit, and a control unit;

[0049] The feeding unit is arranged above the transfer unit, and is used to introduce upstream materials into the transfer barrel 21;

[0050] Wherein, the transfer unit includes an elastic mechanism and a transfer barrel 21, the elastic mechanism is arranged on the frame 5, and the transfer barrel 21 is eccentrically hinged on the elastic mechanism;

[0051] The transfer barrel 21 can rotate around the hinge point to switch between the receiving state and the dumping state;

[0052] The control unit is arranged opposite to the transfer barrel 21, and is used to control the feeding or cutting of the feeding unit according to the action of the transfer barrel 21.

[0053] The transfer unit is used to temporarily accept the materials conveyed by the feeding unit, and at the same time trigg...

Embodiment 2

[0093] An embodiment of the present invention provides a slurry material conveying system, including the above slurry material conveying device.

[0094] Wherein, the specific structure of the slurry material conveying device has been introduced in detail above, and will not be repeated here.

[0095] The system may also include a feeding device and a feeding device, wherein the feeding device is used to deliver materials to the feeding unit, and the feeding device is used to transfer the materials in the tray.

[0096] It can be seen that all the beneficial effects of the above-mentioned slurry material conveying device can be obtained, semi-automatic quantitative delivery of slurry materials can be realized, production costs can be reduced, and production efficiency can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com