Special automatic extruding machine for belt pulley inner hole

A technology of pulley and inner hole, which is applied in the field of automatic extrusion machine for inner hole of pulley, can solve the problems of low efficiency and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

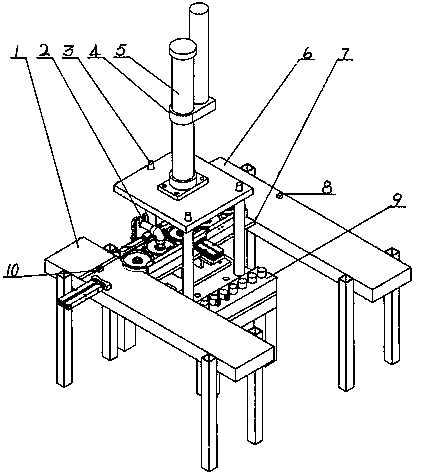

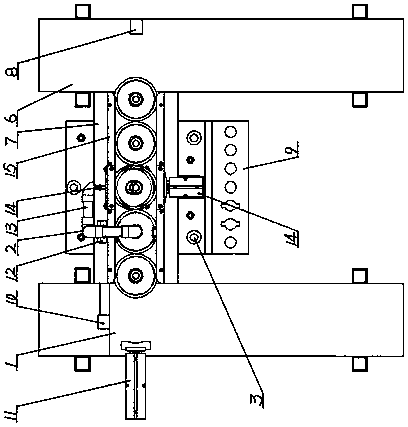

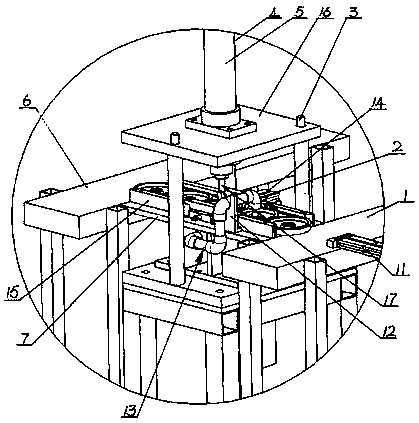

[0021] attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 The automatic extrusion machine for the inner hole of the pulley of the present invention includes a workbench 7 and a push rod 17, and a pressure generating device 4 is arranged above the workbench 7, and the pressure generating device 4 passes through three columns 3 fixed on the frame 21. It is connected with the workbench 7, and the steel ball delivery device 2 is arranged on the workbench 7. The steel ball delivery device 2 is connected with the workbench 7 through the bracket 12 and the support screw 20, so that the steel ball circulation pipeline 13 on the steel ball delivery device 2 The outlet is placed on one side of the feed direction of the ejector rod 17 of the pressure generating device 4 and faces the workbench 7. The inlet of the steel ball circulation pipeline 13 is connected to the workbench 7. A workpiece clamping device 14 is installed at the middle position on the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com