Intelligent gluing device and method for rubber waterstops different in specification

A technology of rubber waterstop and gluing device, which is applied to the device and coating of surface coating liquid, which can solve the problems of reducing production efficiency and low level of database automation, so as to improve production efficiency and precision and avoid measurement Error, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

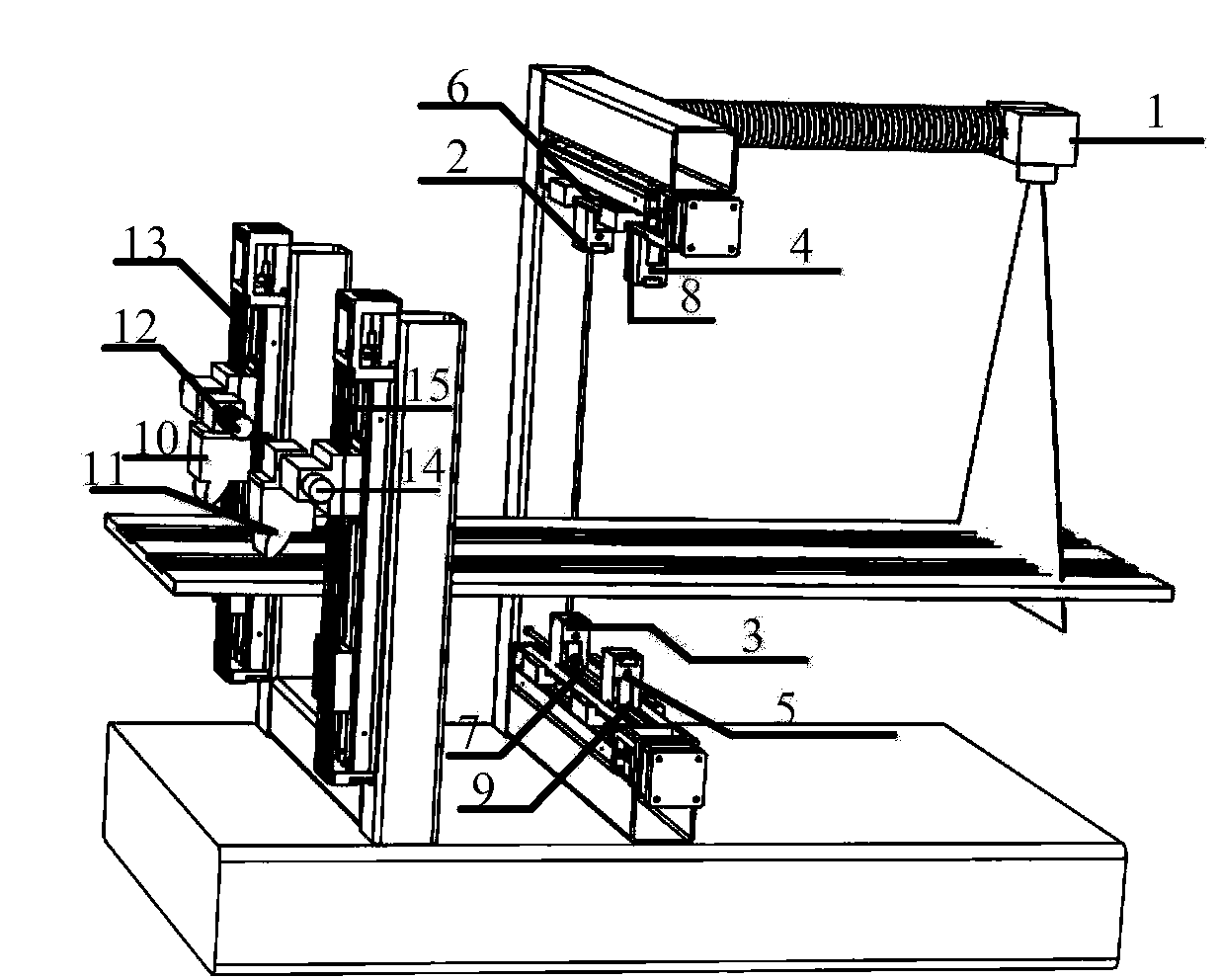

[0033] Embodiment 1, an intelligent gluing device for rubber waterstops of different specifications.

[0034] Such as figure 1 As shown, the intelligent gluing device for rubber waterstops of different specifications provided by the present invention includes a CCD camera 1, an upper left laser head 2, a lower left laser head 3, an upper right laser head 4, a lower right laser head 5, and an upper left screw 6. Left lower screw 7, right upper screw 8, right lower screw 9, left glue gun 10, right glue gun 11, left horizontal screw 12, left vertical screw 13, right horizontal screw 14, right vertical screw 15. Servo motor, ARM control circuit.

[0035] The CCD camera is installed above the measured rubber waterstop and in front of the laser side thickness device. Used to measure the width of the rubber waterstop.

[0036] The left and right pairs of laser heads are symmetrically installed on the left and right sides of the rubber waterstop with the installation axis of the ca...

Embodiment 2

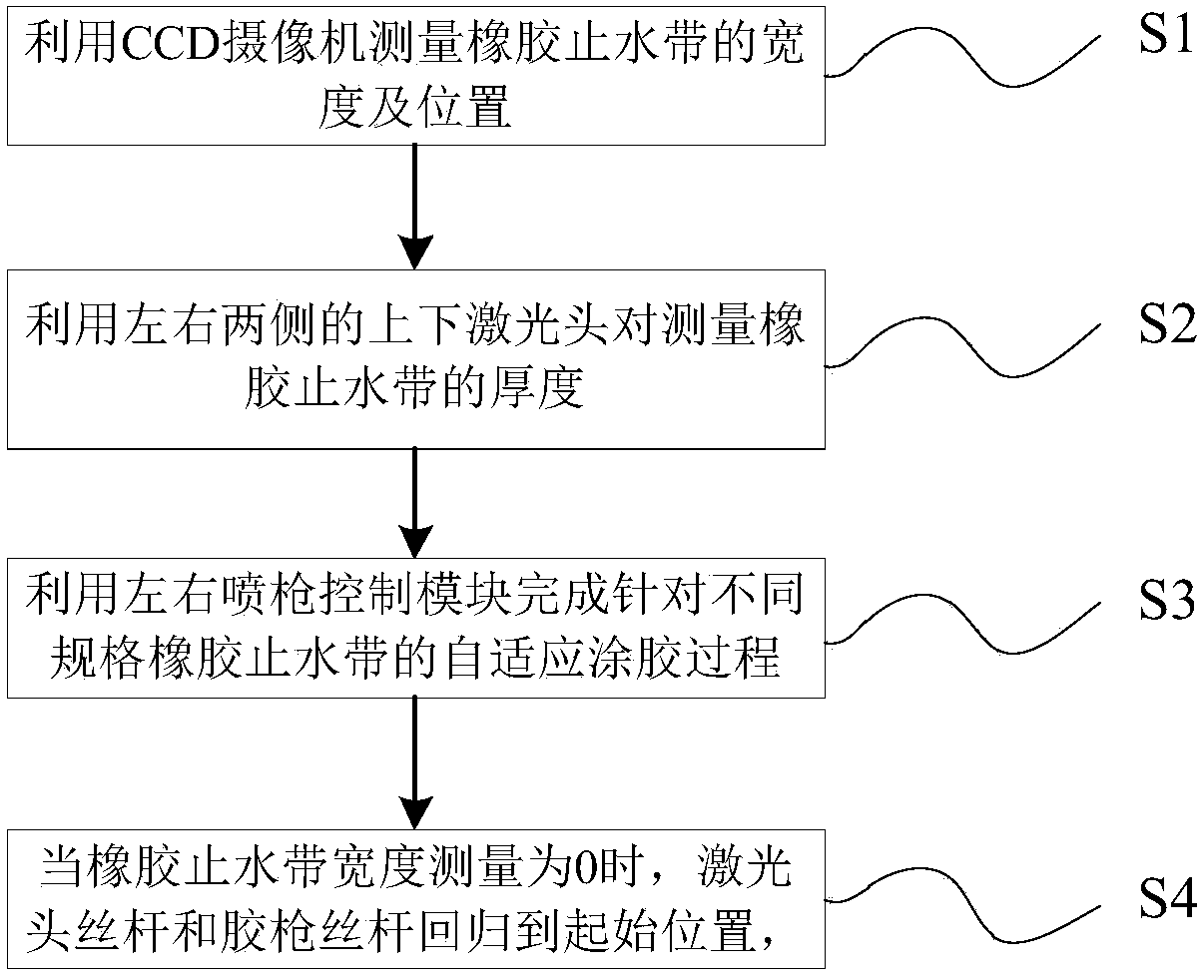

[0038] Embodiment 2, an intelligent gluing method for rubber waterstops of different specifications.

[0039] Such as figure 2 As shown, the intelligent gluing method for rubber waterstops of different specifications provided by the present invention includes the following steps:

[0040] S1. Use a CCD camera to measure the width and position of the rubber waterstop.

[0041] ①. Calibrate the internal and external parameters of the CCD camera according to Zhang Zhengyou’s camera calibration method;

[0042] The plane target used in this calibration is a checkerboard of dimensions. The position of the fixed CCD camera remains unchanged. First, place the plane target parallel to the ground, and ensure that the plane target and the rubber waterstop to be tested are at the same position. Take a plane image of the target at this position, and then rotate the direction of the target to shoot The internal and external parameters of the CCD camera can be obtained by using Zhang Zhen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com