Elastic planet type high-voltage cable ice and snow cleaning robot

A technology for cleaning robots and high-voltage cables, which is applied in the installation of cables, electrical components, overhead installations, etc. It can solve the problems of unable to clean high-voltage cables such as ice and snow, and achieve the effect of quick installation or disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

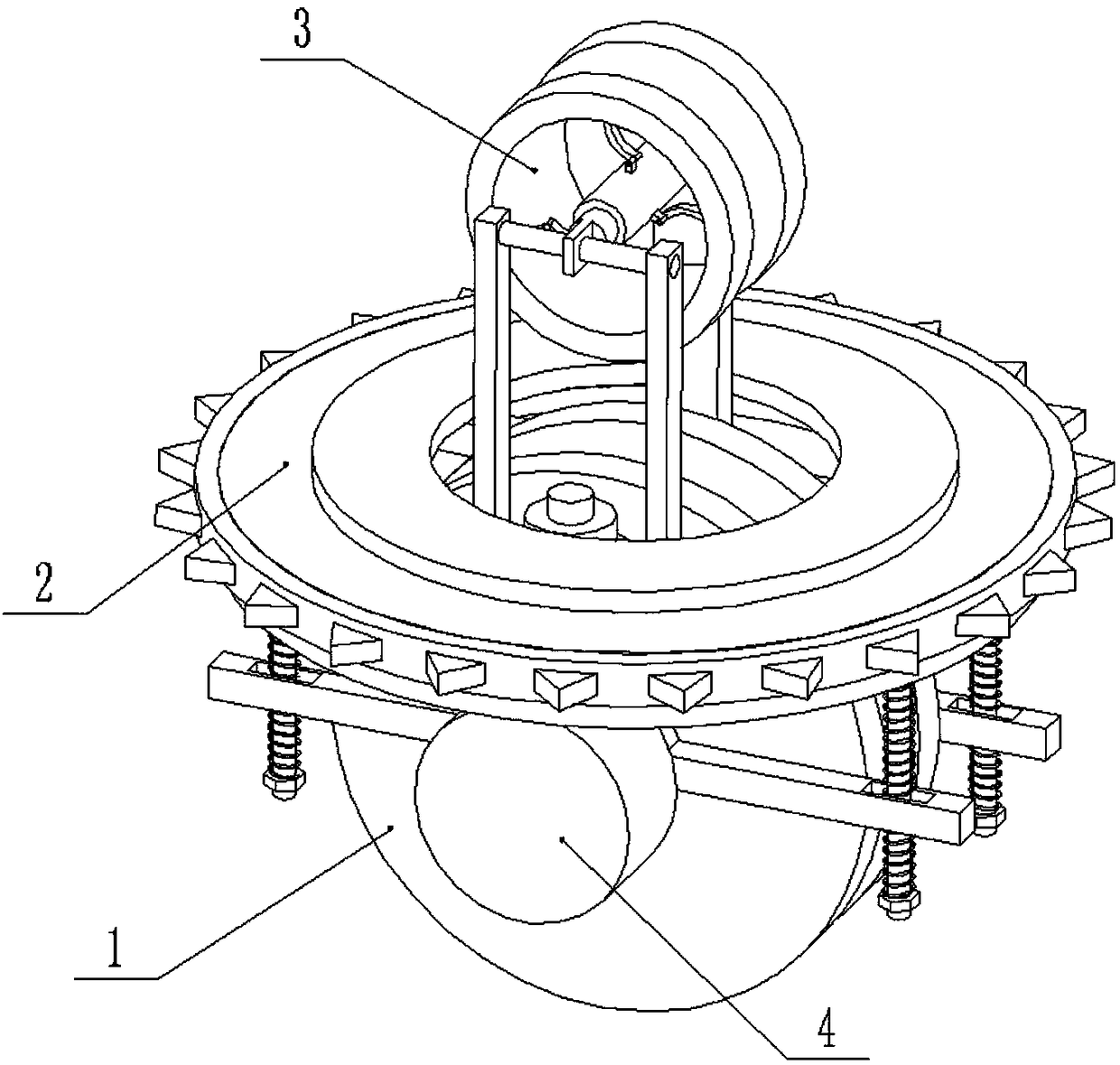

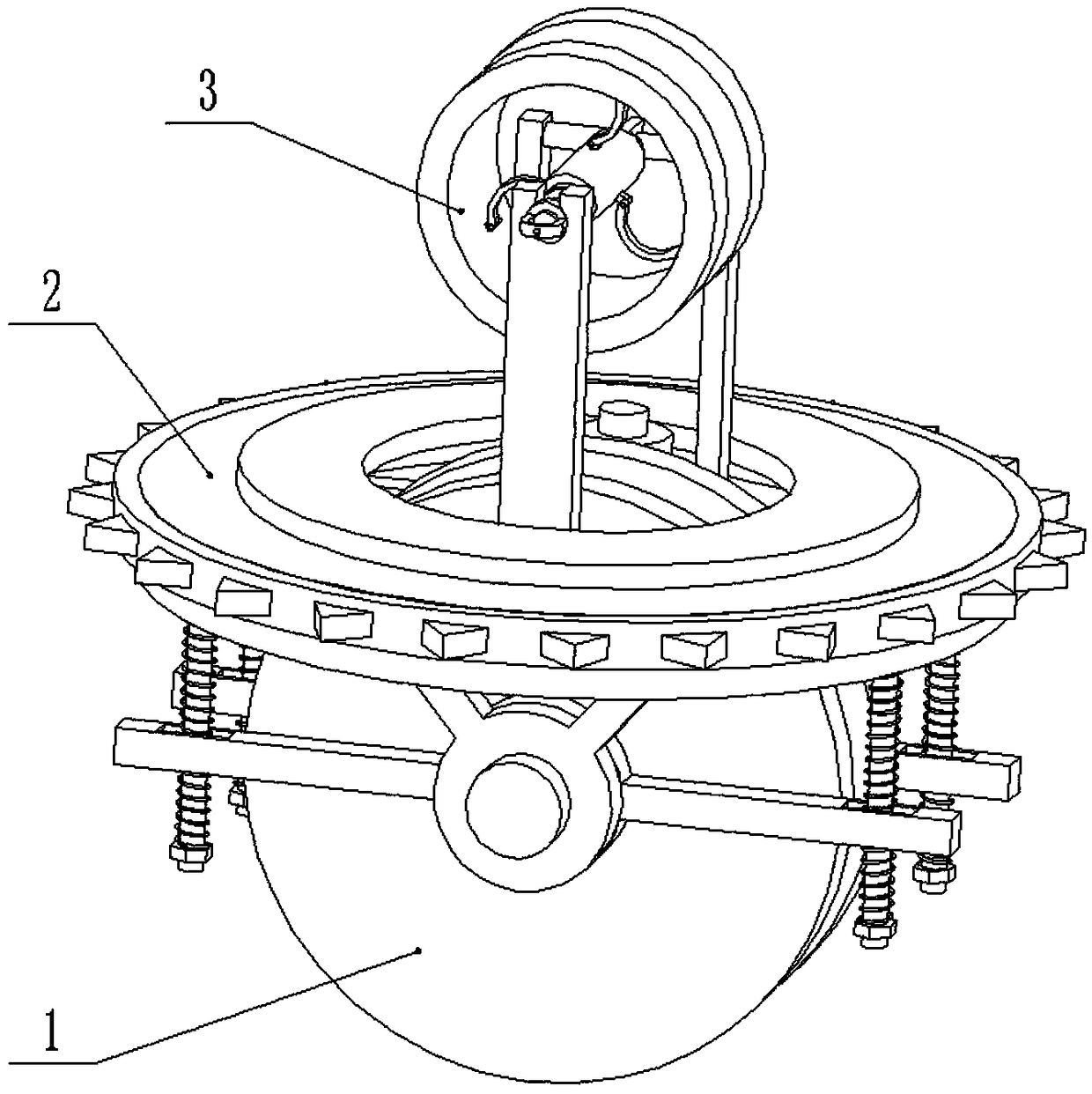

[0032] Combine below Figure 1-12 Describe this embodiment, an elastic planetary high-voltage cable ice and snow cleaning robot, including a traveling wheel assembly 1, a cleaning planetary wheel 2, a pressing wheel assembly 3 and a drive motor 4, and the cleaning planetary wheel 2 is rotatably connected to the traveling wheel assembly 1 The upper end of the cleaning planetary wheel 2 is linked with the traveling wheel assembly 1, the pressing wheel assembly 3 is fixedly connected to the upper end of the traveling wheel assembly 1, and the driving motor 4 is fixedly connected to the traveling wheel assembly 1; when in use , the driving motor 4 drives the traveling wheel assembly 1 to run, the traveling wheel assembly 1 is in contact with the lower end of the cable, the pinch wheel assembly 3 is in contact with the upper end of the cable, and the running wheel assembly 1 drives the elastic planetary high-voltage cable ice and snow cleaning robot to advance along the cable and tr...

specific Embodiment approach 2

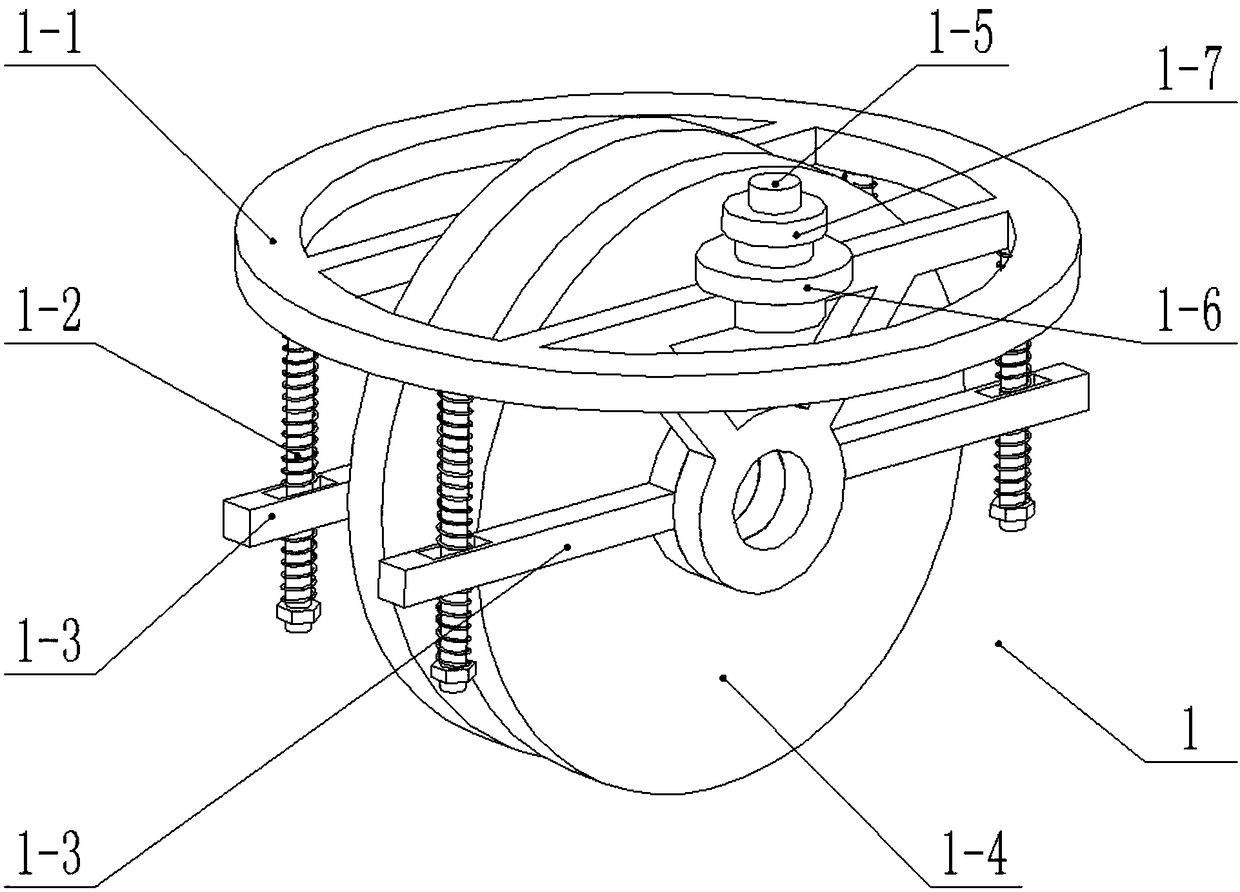

[0033] Combine below Figure 1-12Describe this embodiment, this embodiment will further explain the first embodiment, the travel wheel assembly 1 includes a frame 1-1, an elastic support 1-2, a shaft frame 1-3, a bottom wheel 1-4, and an intermediate shaft 1 -5. Rubber wheels 1-6 and intermediate gears 1-7, the lower end of the frame 1-1 is fixedly connected to four elastic supports 1-2, and the shaft frame 1-3 is provided with two, and the shaft The two ends of the frame 1-3 are respectively slidably connected to the middle end of an elastic support 1-2, the drive motor 4 is fixedly connected to the frame 1-1, and the rotating shaft of the drive motor 4 is rotatably connected to the frame 1-1 and the shaft frame 1-3, the bottom wheel 1-4 is fixedly connected to the transmission shaft of the drive motor 4, the bottom wheel 1-4 is located between the two shaft frames 1-3, and the middle Shaft 1-5 is rotatably connected to frame 1-1, said intermediate gear 1-7 and rubber wheel ...

specific Embodiment approach 3

[0034] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the second embodiment, the frame 1-1 includes an outer shaft frame 1-1-1, an intermediate shaft hole 1-1-2 and an annular wheel frame 1-1-3 , the upper end of the outer shaft frame 1-1-1 is provided with an intermediate shaft hole 1-1-2, and the annular wheel frame 1-1-3 is fixedly connected to the upper end of the outer shaft frame 1-1-1, and the middle The shaft 1-5 realizes the axial positioning in the intermediate shaft hole 1-1-2 by positioning the shaft shoulder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com