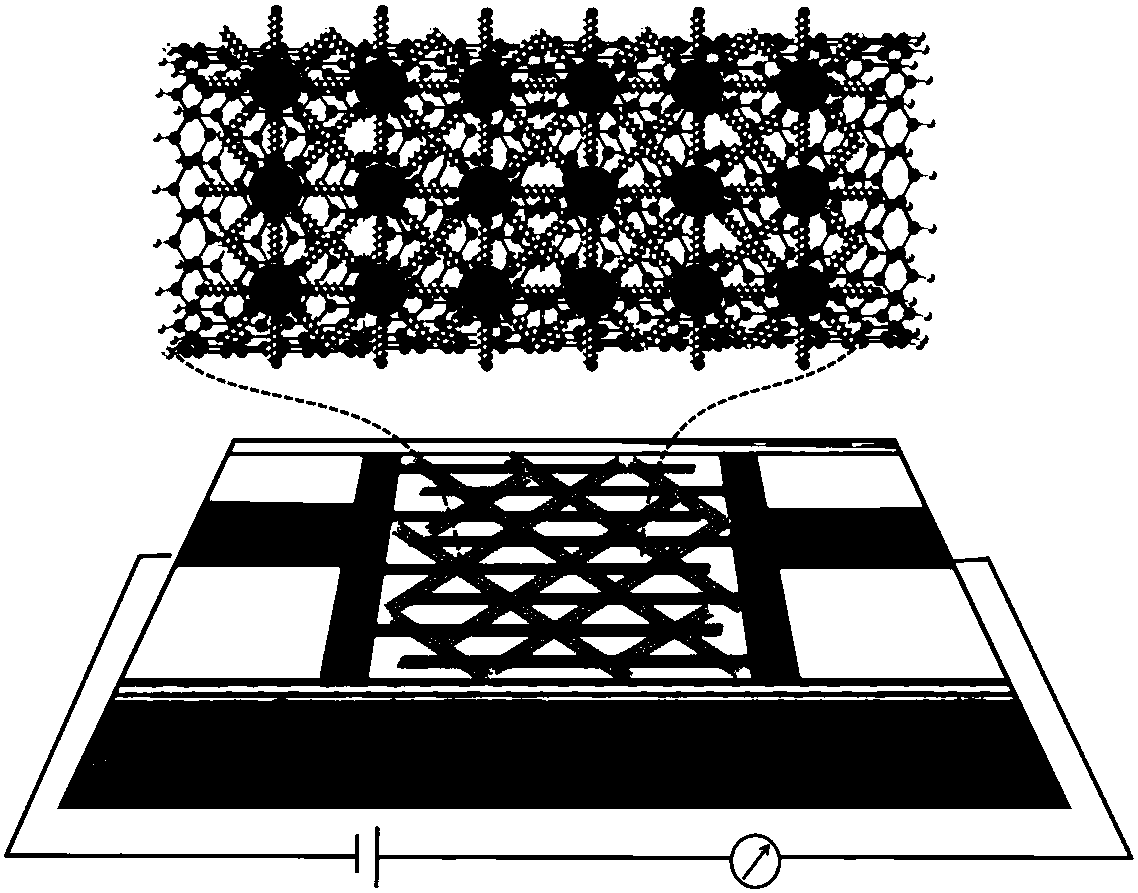

Gas sensor based on carbon nanotubes and metal nanoparticles and construction method thereof

A technology of metal nanoparticles and gas sensors, applied in the direction of material electrochemical variables, etc., to achieve the effect of scientific construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The process and steps of using carbon nanotubes and metal nanoparticles to construct methanol sensors are as follows:

[0027] 1) Thiol-covered gold nanoparticles

[0028] 1.5×10 ‐2 mol / L of HAuCl 4 Solution 50ml, add 1.6×10 ‐2 The tetraoctylammonium bromide / toluene 50ml of mol / L mmol forms organic phase, adds 1.5 * 10 ‐4 mol / L of decylthiol (CH 3 (CH 2 ) 9 SH) 10ml and 25mL of 0.25mol / L sodium borohydride solution, by stirring overnight to obtain decanethiol (CH 3 (CH 2 ) 9 SH) covered gold nanoparticles with a size of ~2 nm, after which 2.0 × 10 ‐2 mol / L of 1,9‐nonanedithiol (HS(CH 2 ) 9 SH) 10ml, through the replacement principle, use 1,9‐nonanedithiol (HS(CH2)9SH) to replace decylthiol (CH3(CH2) on the particle surface 9 SH).

[0029] 2) Assembling nanoparticles on carbon nanotubes

[0030] The purchased multi-walled carbon nanotubes (diameter ~ 23 nanometers) are dispersed in hexane so that the mass concentration is 0.30 mg / ml, and the above-mentioned...

Embodiment 2

[0038] The process and steps of using carbon nanotubes and metal nanoparticles to construct 1-propanol sensors are as follows:

[0039] 1) Thiol-covered gold nanoparticles

[0040] 1.7×10 ‐2 mol / L of HAuCl 4 Solution 50ml, add 1.6×10 ‐2 The tetraoctylammonium bromide / toluene of mol / L forms organic phase 50ml, adds 1.7×10 ‐4 mol / L of decylthiol (CH 3 (CH 2 ) 9 SH10ml and 25mL 0.28mol / L sodium borohydride solution, by stirring overnight to obtain decyl mercaptan (CH 3 (CH 2 ) 9 SH) covered gold nanoparticles with a size of ~3 nm, after which 2.4 × 10 ‐2 mol / L of 1,9‐nonanedithiol (HS(CH 2 ) 9 SH) 10ml, through the replacement principle, use 1,9‐nonanedithiol (HS(CH2)9SH) to replace decylthiol (CH3(CH2) on the particle surface9 SH).

[0041] 2) Assembling nanoparticles on carbon nanotubes, the method is the same as in Example 1. The type, concentration and process of the reagents used remained unchanged.

[0042] 3) The complex is assembled on the surface of the mic...

Embodiment 3

[0048] The process and steps of using carbon nanotubes and metal nanoparticles to construct a toluene sensor are as follows:

[0049] 1) Gold nanoparticles covered with thiol, the method is the same as in Example 1. The type, concentration and process of the reagents used remained unchanged.

[0050] 2) Assembling nanoparticles on carbon nanotubes, the method is the same as in Example 1. The type, concentration and process of the reagents used remained unchanged.

[0051] 3) The complex is assembled on the surface of the microelectrode, and the method is the same as in Example 1. The type, concentration and process of the reagents used remained unchanged.

[0052] 4) Sensing device and signal collection

[0053] The aforementioned microelectrode was placed in a custom-made air chamber made of Teflon material, with the size of a 2 cm long cube. Toluene of 100ppm, 200ppm, 300ppm, 500ppm, 600ppm (ppm means milligram per liter) was brought into the air chamber made of Teflon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com