Device and method for measuring high pressure leakage of injector nozzle matching part

A technology of fuel injectors and compression devices, which is applied in the direction of measuring devices, fuel injection devices, and charging systems, and can solve the problems of inability to test the seal of fuel injectors and structural strength assessment, and the inability to effectively inspect the high-pressure sealing of fuel injectors, etc. problem, to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings.

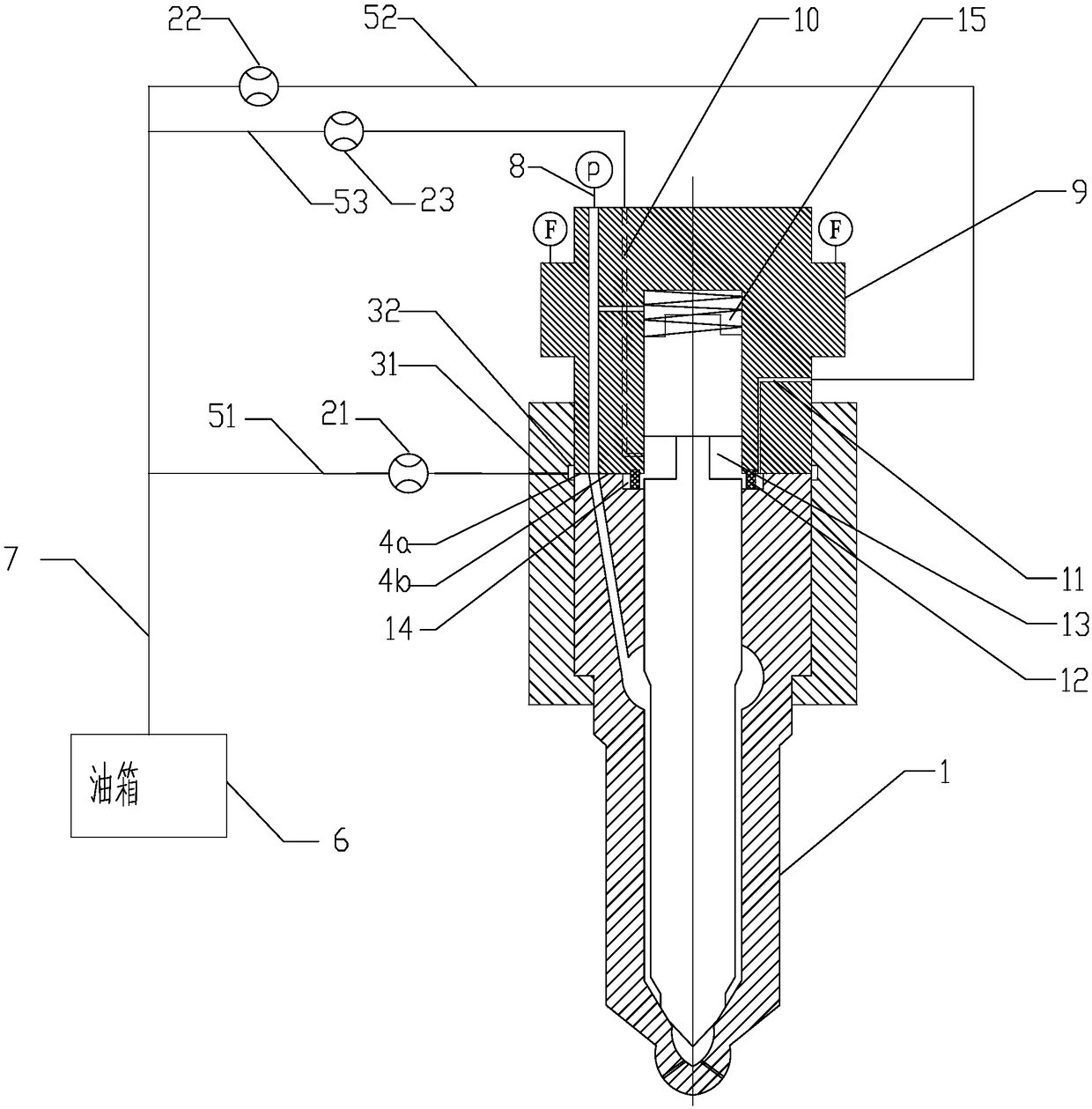

[0026] like figure 1 As shown, the device for measuring the high-pressure leakage of the injector assembly in the present invention includes a test oil passage 8, a first flow meter 21, a second flow meter 22, a third flow meter 23, a first connecting pipe 51, a second connecting pipe The pipeline 52, the third connecting pipeline 53 and the fuel tank 6; the fuel injector assembly 1 is placed on the fuel injector fastening seat, and there are 9 pairs of clamping devices consisting of a clamping block 91, a piston 92, a spring 93 and tightening bolts The injector assembly is compressed with the set pressure to form the first sealing surface 4a and the second sealing surface 4b. The first sealing surface 4a is located outside the oil inlet of the injection nozzle assembly 1, and the second sealing surface The surface 4b is located inside the oil inlet of the nozzle assembly 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com