A formwork support method for construction joints between double walls

A technology for construction joints and formwork, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve problems such as inability to fix, environmental pollution, and leakage of reinforcement, saving manpower and material resources, and solving technical problems. Problems, the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

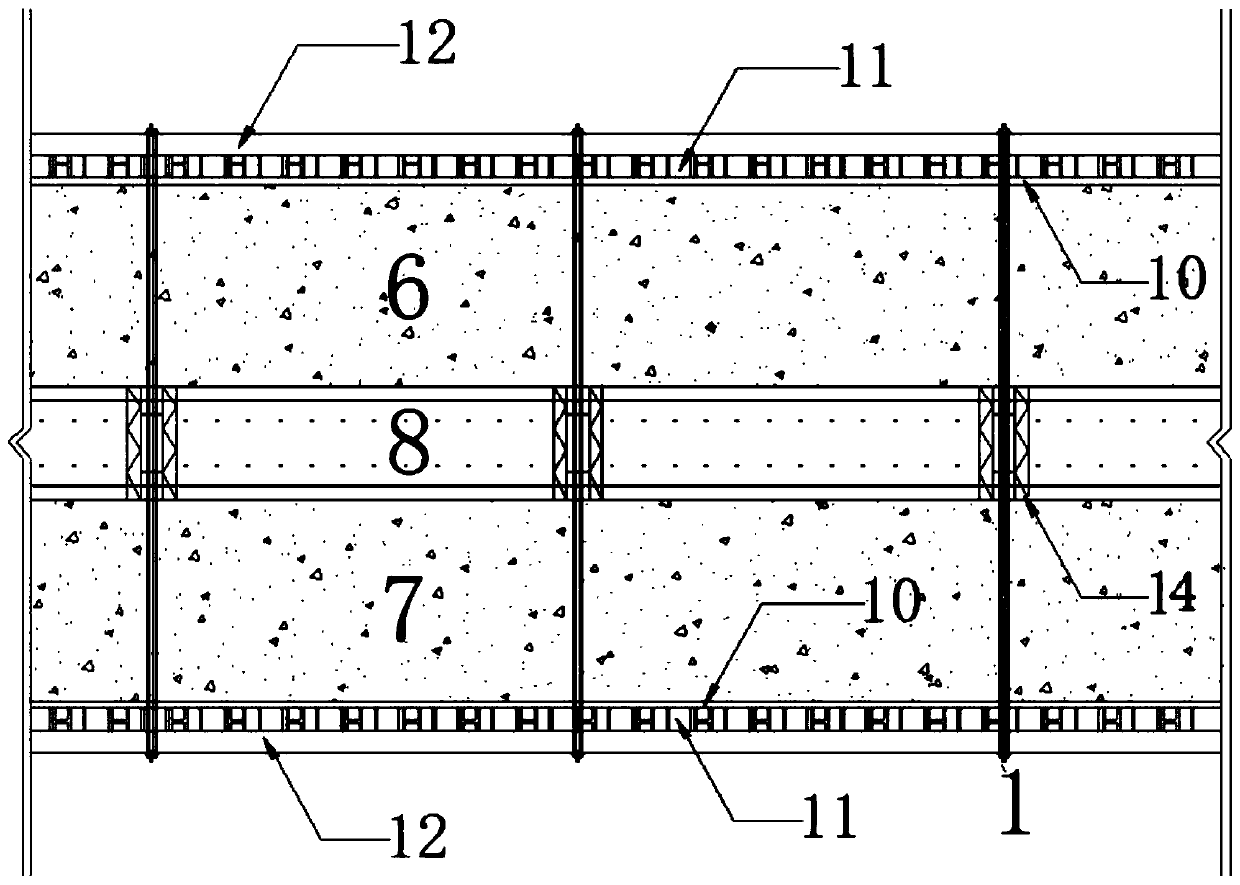

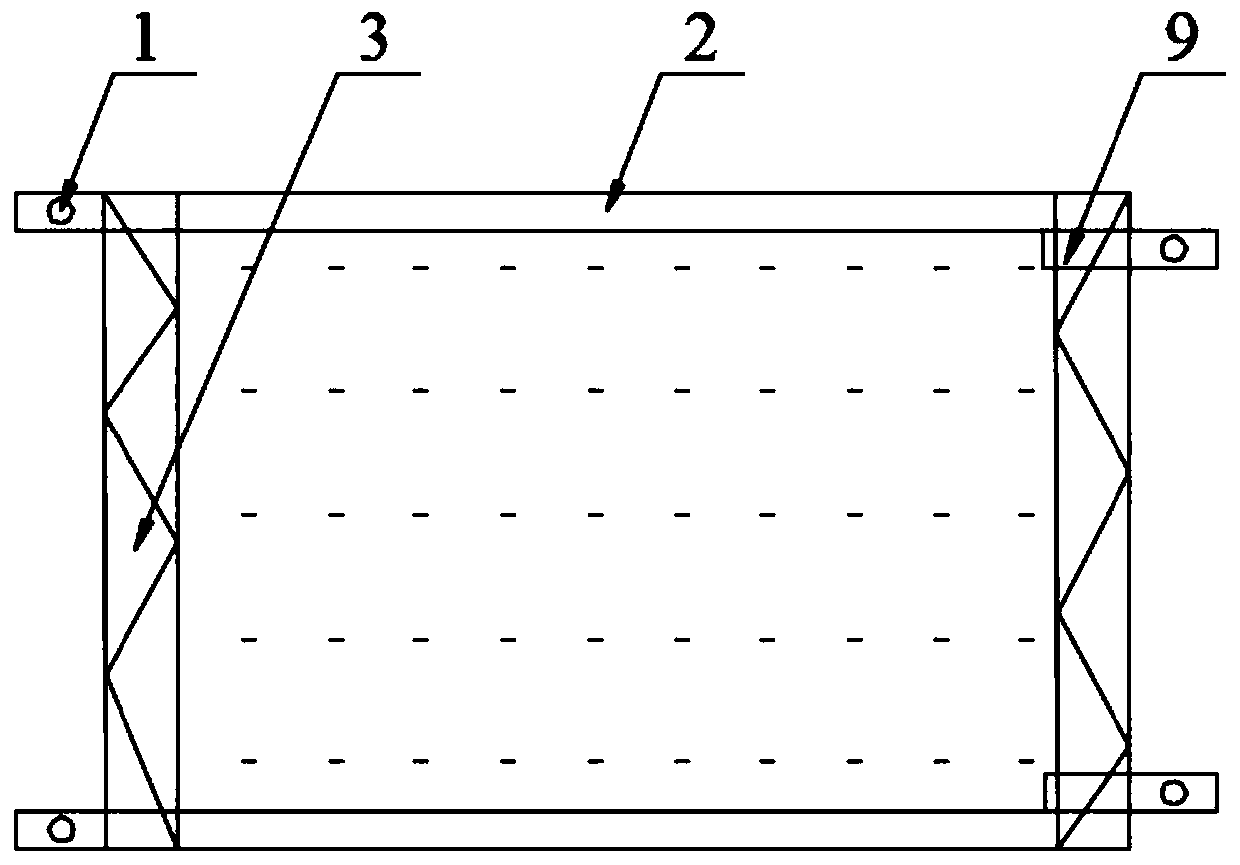

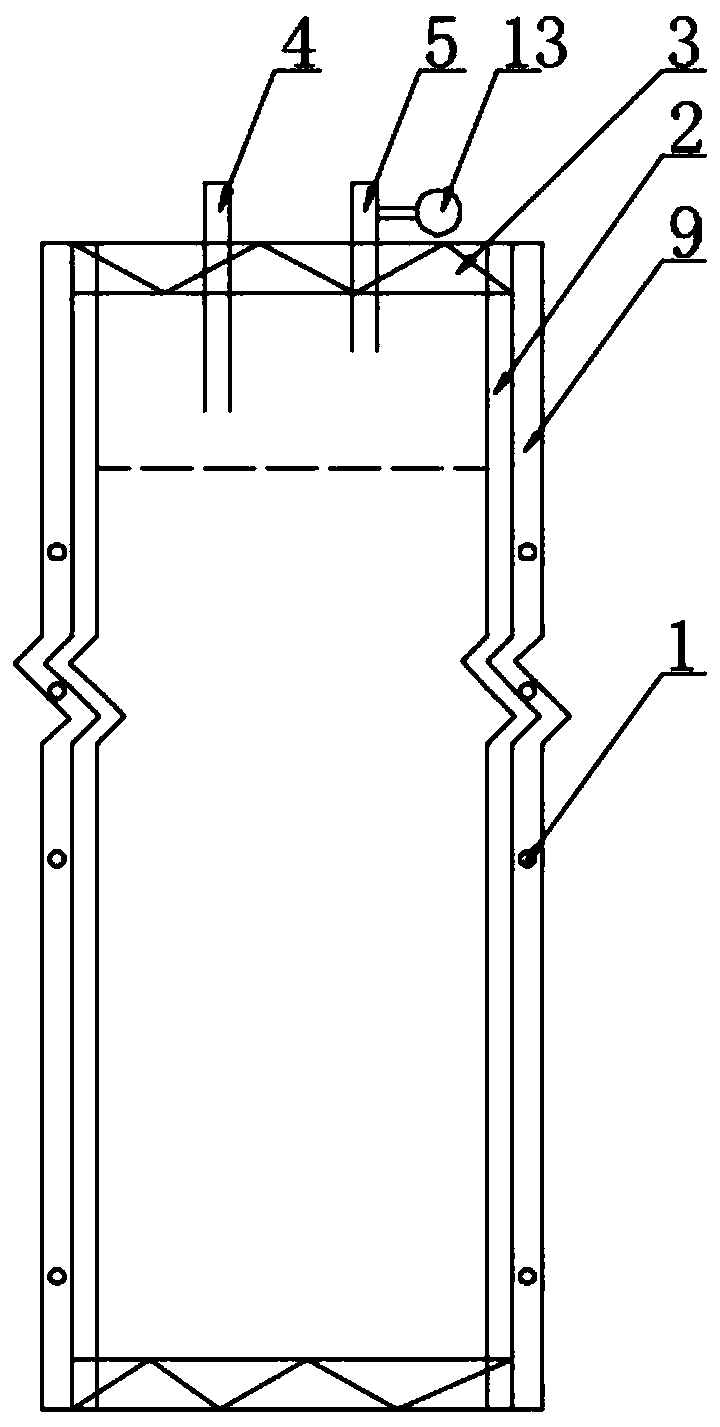

[0023] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

[0024] (1) Construction of the first concrete wall 6, and prefabrication of multiple tension bolt holes on the first concrete wall, and the horizontal spacing of the multiple tension bolt holes is 1050mm, and the vertical spacing is 500mm; the first surface After the concrete wall is poured, its pouring formwork is removed, and the construction of the second concrete wall 7 is carried out, and the second concrete wall needs to be prefabricated to be the same as the multiple tension bolt holes on the first concrete wall. the pull bolt holes;

[0025] (2) Make a sealed gas support unit 8, which includes a steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com