Rotary spraying quenching device and rotary spraying quenching method for high-chromium wear-resistant iron castings

A technology of rotating spray and quenching device, applied in the field of casting quenching, can solve the problems of local temperature rise, affecting the quenching effect, time-consuming and laborious, etc., and achieve the effect of improving the quenching quality of the workpiece, cooling rapidly and uniformly, and improving the quenching quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

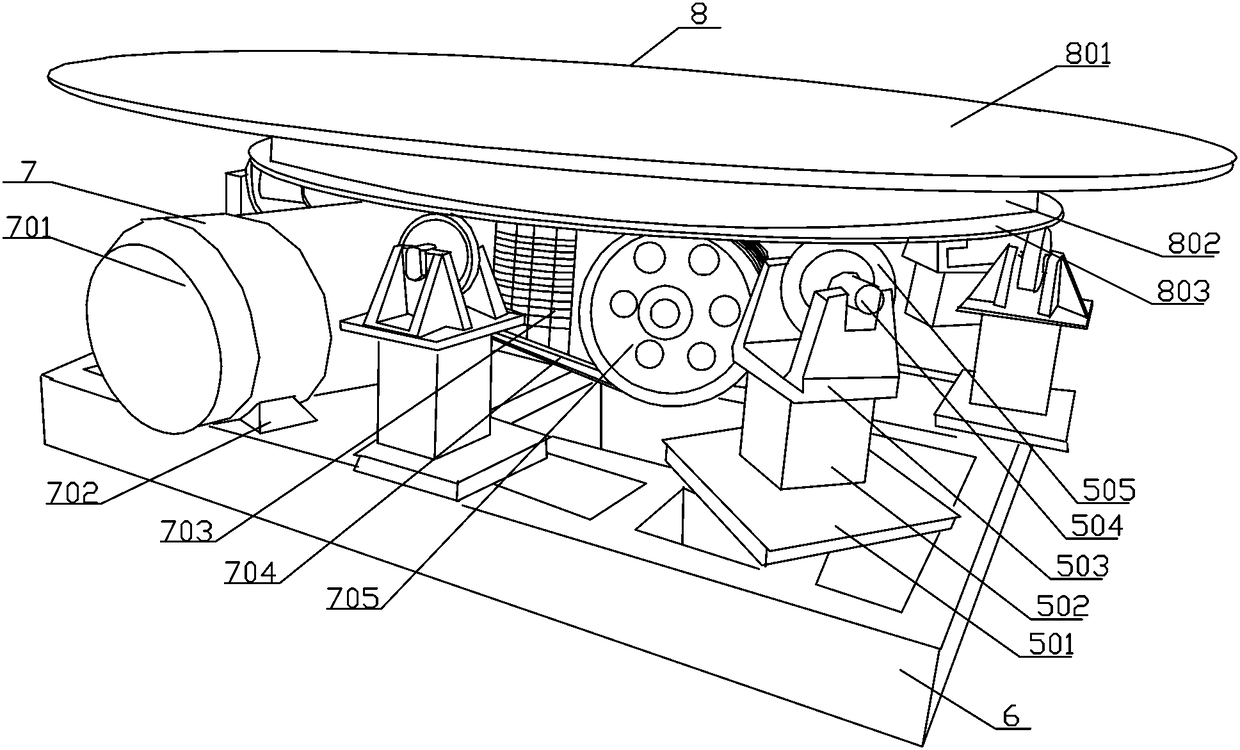

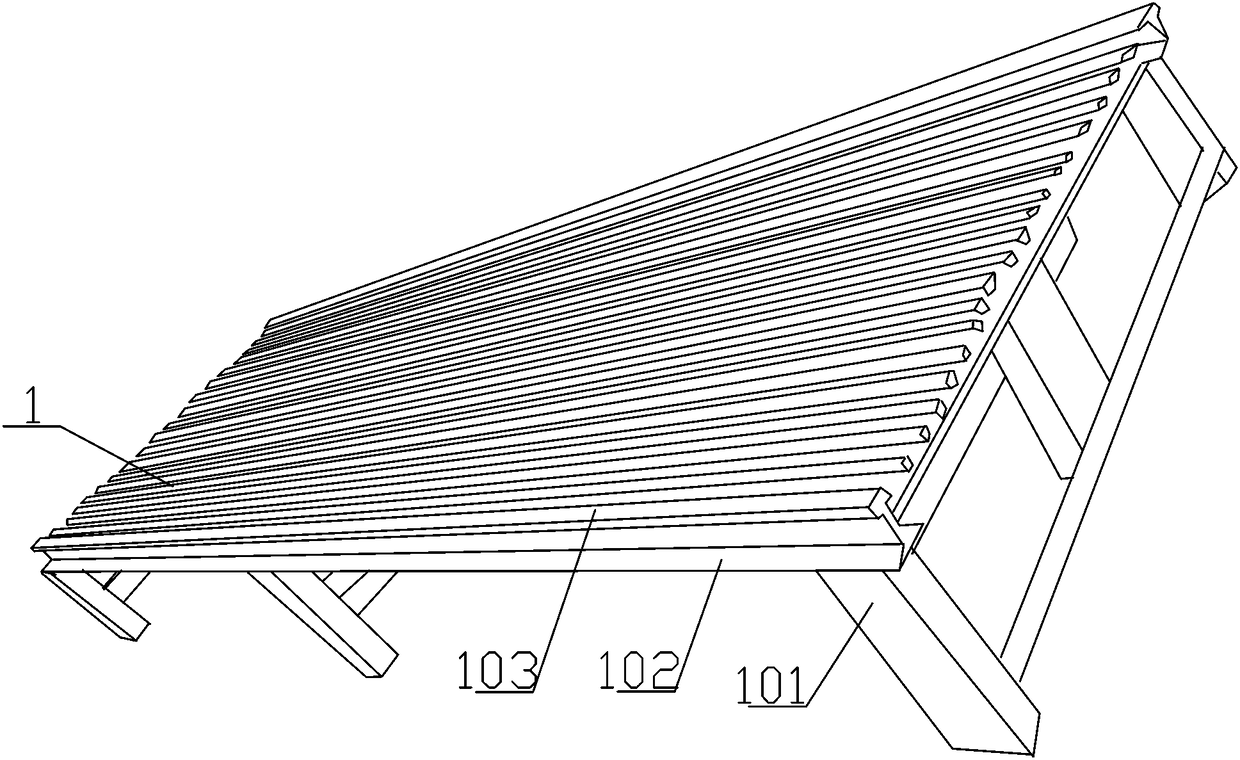

[0045] see Figure 1-3 , high chromium wear-resistant cast iron rotary spray quenching device, which includes a base 6, the top of the base 6 is evenly provided with a plurality of turntable support assemblies 5, the top of the turntable support assembly 5 supports a rotating disk device 8 , the rotary disk device 8 is connected to the rotary power device 7 at its bottom, and drives the rotary disk device 8 to rotate; a first support frame device 3 is arranged on the side of the rotary disk device 8, and the top of the first support frame device 3 A plurality of spraying devices 4 for spraying are adjustablely installed, and the spraying devices 4 are connected to a water source through a water supply pipe 11 . By adopting the above-mentioned mist quenching equipment, it can be used to spray quench the casting workpiece. During the quenching process, the casting workpiece 10 placed on the top of the rotating disk device 8 is sprayed by the spray device 4, thereby realizing the...

Embodiment 2

[0055] The quenching process of any one of the high-chromium wear-resistant cast iron rotary spray quenching device, it includes the following steps:

[0056] Step1: Place the heated casting workpiece 10 on the top of the rotary table 801 of the rotary disk device 8;

[0057] Step2: According to the quenching process conditions required by the casting workpiece 10, the control device 2 is started, and the rotary power device 7 and the spray device 4 are controlled by the control device 2 to start;

[0058] Step3: Drive the rotary table 801 of the rotary disc device 8 to rotate at high speed through the motor 701 of the rotating power device 7, and start the spray fan 402 of the spray device 4 at the same time, open the water supply pipe 11, and spray the water evenly through the spray fan 402 after atomization. On the rotating casting workpiece 10;

[0059] Step4: According to the quenching process requirements of the cast workpiece 10, control the rotation speed of the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com