Water-based strong-weather-resistant self-repairing two-component polyurethane topcoat and preparation method thereof

A two-component polyurethane, weather resistance technology, applied in the field of coatings, can solve the problems of poor weather resistance, poor self-healing ability, etc., and achieve the effect of prolonging the shelf life, obvious self-healing ability, and low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] And, the embodiment of the present invention also provides a method for preparing a water-based weather-resistant and self-repairable two-component polyurethane topcoat. The preparation method at least includes the following steps:

[0033] Step a, according to the raw material formula of the above-mentioned two-component polyurethane topcoat with strong water-based weather resistance and self-repairing, weigh each raw material component, mix 50-70% deionized water, 40-60% neutralizer, defoaming Add agent, dispersant, 15-25% co-solvent, and pigment into the stock preparation pot in sequence, and after mixing evenly, grind to obtain the early stage slurry;

[0034] Step b, adding the water-based hydroxyacrylic acid emulsion and the remaining deionized water, neutralizing agent, and co-solvent into the mixing container in sequence, and mixing evenly;

[0035] Step c, adding the pre-phase slurry into the mixture obtained in step b, and mixing evenly;

[0036] Step d, add wa...

Embodiment 1

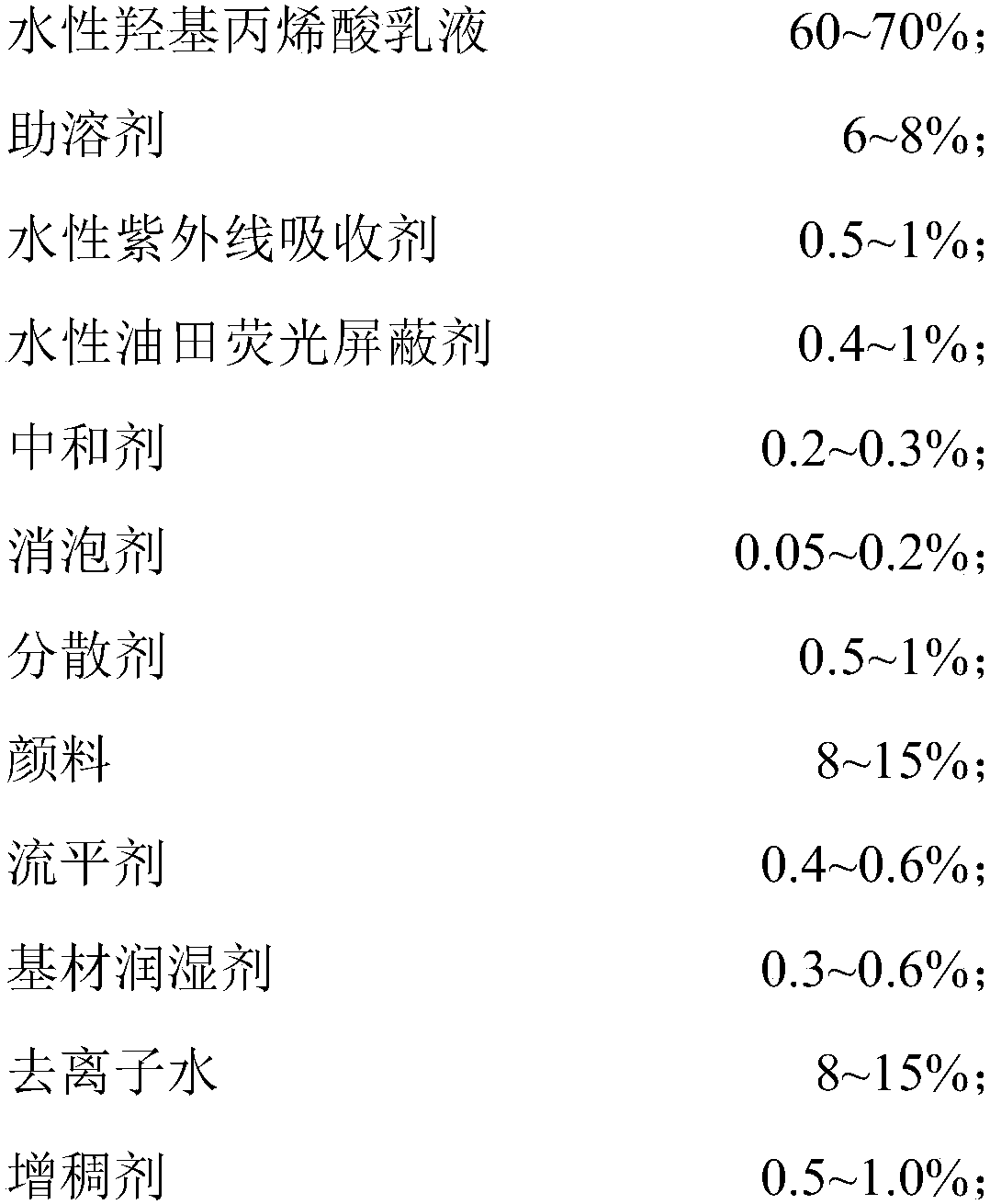

[0045] The embodiment of the present invention provides a two-component polyurethane topcoat with strong water-based weather resistance and self-healing, which is formed by mixing a group A mixture and a group B mixture, and the group A mixture includes the following raw materials in weight percentage:

[0046]

[0047] The group B mixture includes aliphatic isocyanate and ester organic solvent, wherein the weight of the aliphatic isocyanate accounts for 75wt% of the total weight of the aliphatic isocyanate and the ester organic solvent;

[0048] The mass ratio of the mixture of the group A to the mixture of the group B is the mixture of the group A:the mixture of the group B=4.5:1.

[0049] Among them, the water-based hydroxyl acrylic emulsion is the high-gloss acrylic dispersion A2743 of Shanghai Yuanhe Chemical Co., Ltd., the curing agent is Bayer's aliphatic isocyanate N3900, the co-solvent is propylene glycol butyl ether, and the water-based ultraviolet absorber UV326 p...

Embodiment 2

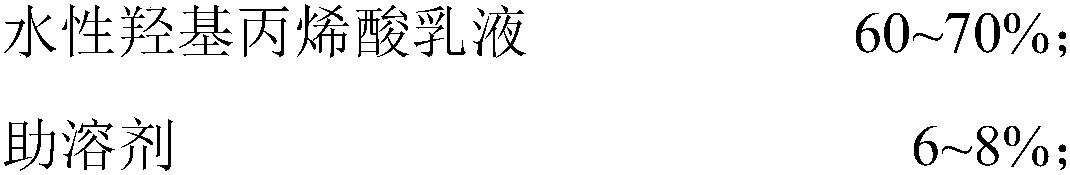

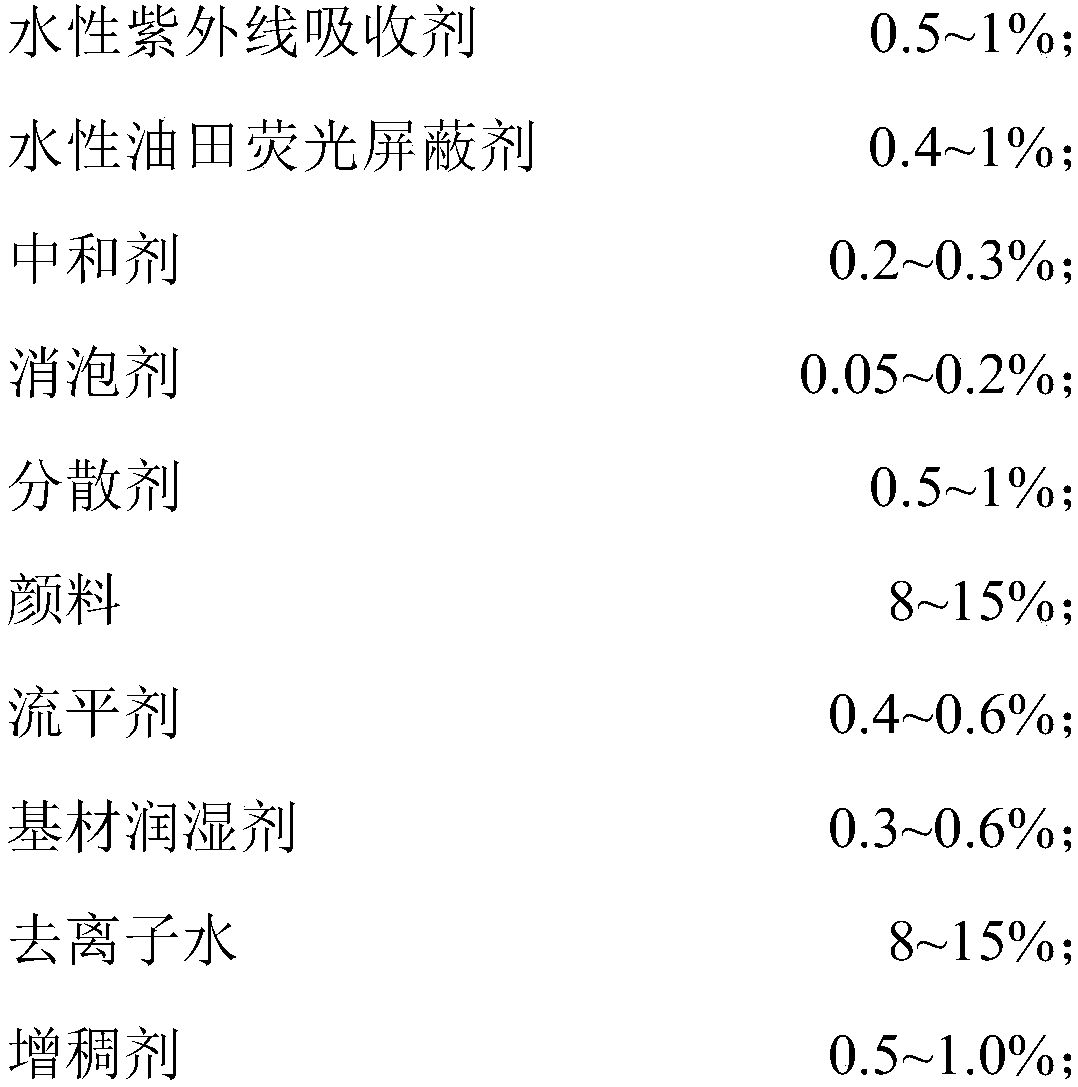

[0058] The embodiment of the present invention provides a two-component polyurethane topcoat with strong water-based weather resistance and self-healing, which is formed by mixing a group A mixture and a group B mixture, and the group A mixture includes the following raw materials in weight percentage:

[0059]

[0060]

[0061] The group B mixture includes aliphatic isocyanate and ester organic solvent, wherein the weight of the aliphatic isocyanate accounts for 75wt% of the total weight of the aliphatic isocyanate and the ester organic solvent;

[0062] The mass ratio of the mixture of the group A to the mixture of the group B is the mixture of the group A:the mixture of the group B=4.5:1.

[0063] Among them, the water-based hydroxyl acrylic emulsion is the high-gloss acrylic dispersion A2743 of Shanghai Yuanhe Chemical Co., Ltd., the curing agent is Bayer's aliphatic isocyanate N3900, the co-solvent is propylene glycol methyl ether, and the water-based ultraviolet abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com