Ion liquid modified cellulose-based adsorbent as well as preparation method and application thereof

A cellulose-based, ionic liquid technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc. Low toxicity, safe reaction process, and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

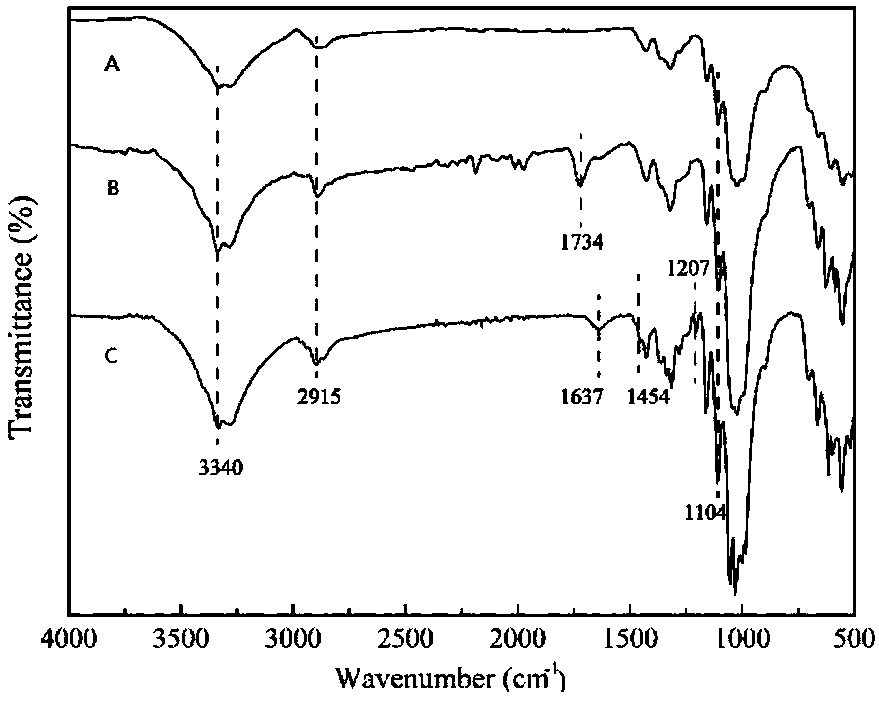

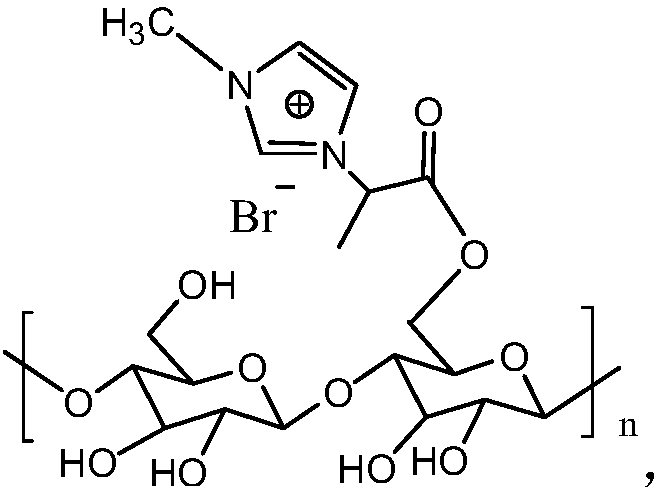

Method used

Image

Examples

Embodiment 1

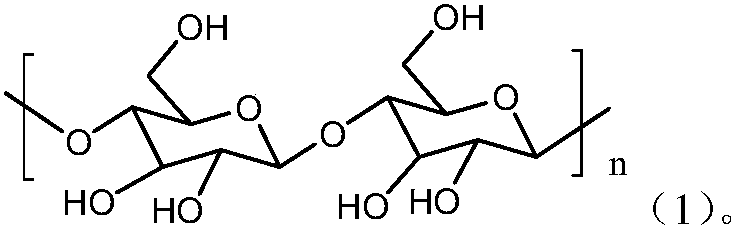

[0030] A preparation method of ionic liquid modified cellulose-based adsorbent, comprising the following steps:

[0031] 1) Accurately weigh 2g of absolute dry cellulose (handmade cotton pulp paper), add it together with 17.6g of 2-bromopropionic acid, 0.14g of p-toluenesulfonic acid, and 80mL of toluene into a 100mL container (such as a single-necked flask), and put Insert the magnetic rotor, connect the water separator, add 3 / 4 toluene to the side pipe of the water separator, and connect the condenser pipe;

[0032] 2) Place the container in an oil bath at 130°C and heat it at a constant temperature. After condensing and refluxing for 10 hours, open the side pipe piston of the water separator, slowly release the toluene-water mixture in the side pipe, and gradually evaporate the toluene in the container to obtain fiber The crude product of 2-bromopropionate;

[0033] 3) Rinse the crude cellulose 2-bromopropionate with ethanol and 5% sodium bicarbonate aqueous solution for s...

Embodiment 2

[0038] A preparation method of ionic liquid modified cellulose-based adsorbent, comprising the following steps:

[0039] 1) Accurately weigh 2g of absolute dry cellulose (handmade cotton pulp paper), add it together with 17.6g of 2-bromopropionic acid, 0.14g of p-toluenesulfonic acid, and 80mL of toluene into a 100mL container (such as a single-necked flask), and put Insert the magnetic rotor, connect the water separator, add 3 / 4 toluene to the side pipe of the water separator, and connect the condenser pipe;

[0040] 2) Place the container in an oil bath at 110°C and heat it at a constant temperature. After condensing and refluxing for 10 hours, open the side pipe piston of the water separator, slowly release the toluene-water mixture in the side pipe, and gradually evaporate the toluene in the container to obtain fiber The crude product of 2-bromopropionate;

[0041] 3) Rinse the crude cellulose 2-bromopropionate with ethanol and 5% sodium bicarbonate aqueous solution for s...

Embodiment 3

[0045] A preparation method of ionic liquid modified cellulose-based adsorbent, comprising the following steps:

[0046] 1) Accurately weigh 2g of absolute dry cellulose (handmade cotton pulp paper), add it together with 17.6g of 2-bromopropionic acid, 0.14g of p-toluenesulfonic acid, and 80mL of toluene into a 100mL container (such as a single-necked flask), and put Insert the magnetic rotor, connect the water separator, add 3 / 4 toluene to the side pipe of the water separator, and connect the condenser pipe;

[0047] 2) Place the container in an oil bath at 130°C and heat it at a constant temperature. After condensing and refluxing for 7 hours, open the side pipe piston of the water separator, slowly release the toluene-water mixture in the side pipe, and gradually evaporate the toluene in the container to obtain fiber The crude product of 2-bromopropionate;

[0048] 3) Rinse the crude cellulose 2-bromopropionate with ethanol and 5% sodium bicarbonate aqueous solution for seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com