Speaker mesh with composite waterproof structure and manufacturing technology of such speaker mesh

A technology of waterproof structure and speaker mesh, which is applied in the direction of electrical components, loudspeakers, sensors, etc., can solve the problems of waterproof membrane fragility, waterproof membrane rupture, and loss of waterproof performance, so as to improve waterproof performance, improve efficiency, and improve waterproof performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

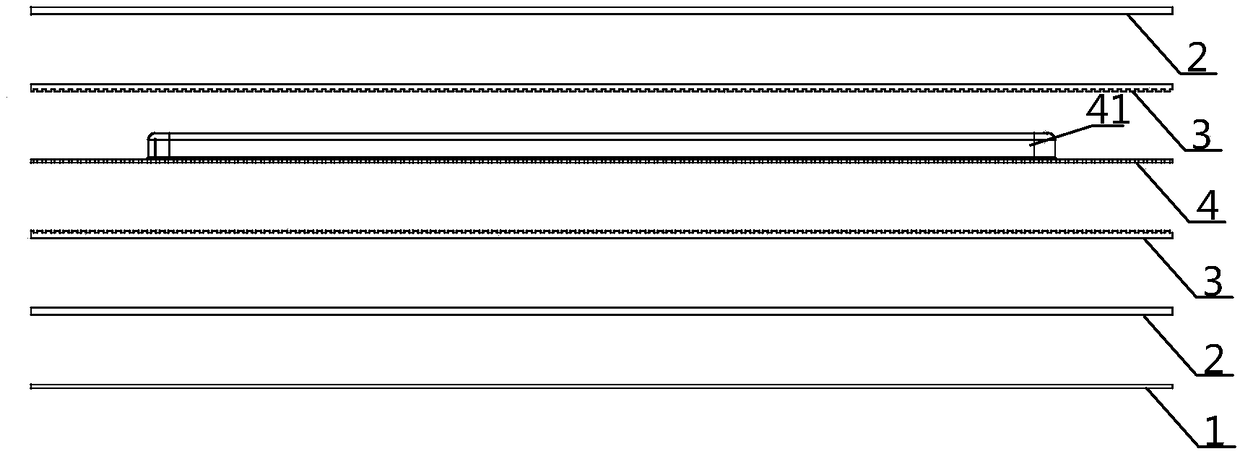

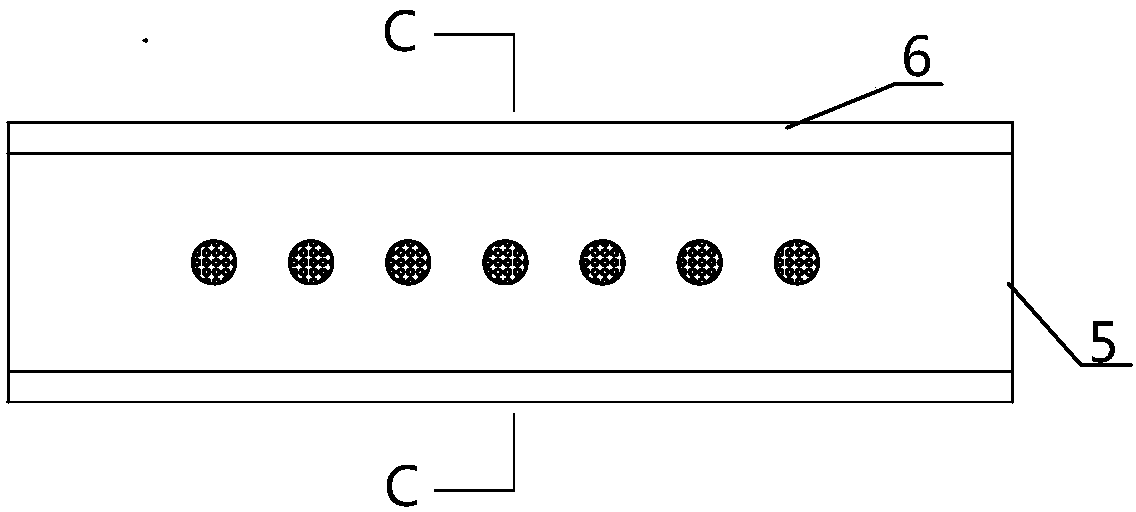

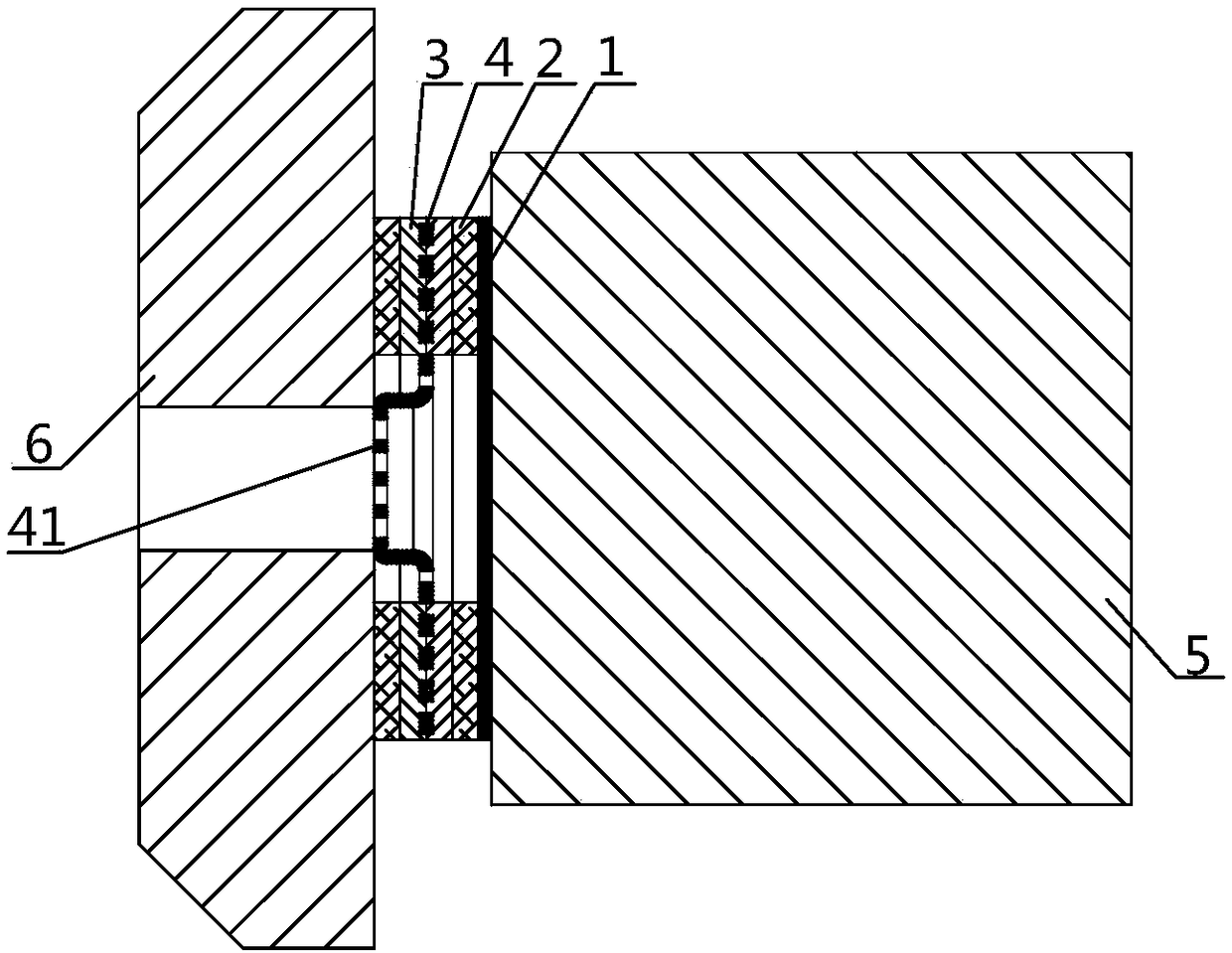

[0045] Such as figure 1 , figure 2 , diagram 2-1 , Figure 2-2 , Figure 4 As shown, the speaker mesh with a composite waterproof structure described in Embodiment 1 of the present invention, the purpose of the technical means to be implemented is that the traditional speaker mesh structure (including the earpiece mesh, microphone mesh, etc.) adopts double-sided adhesive waterproof Structure, this kind of sticking method, cannot ensure that it is truly combined with the holes of the central metal mesh layer of the speaker mesh structure. Therefore, it is necessary to solve the problem that the speaker mesh is difficult to ensure that each center metal mesh layer The holes can be fitted in place, resulting in the problem of water seepage. For this reason, if the technical solution adopted in the present invention is applied to the outer layer of the microphone assembly 6, then the speaker net with a composite waterproof structure is realized based on the outer layer struct...

Embodiment 2

[0057] Such as figure 1 , image 3 , Figure 3-1 , Figure 3-2 , Figure 4 As shown, the loudspeaker net with composite waterproof structure described in Embodiment 2 of the present invention is an improvement on different application examples based on Embodiment 1. It belongs to the same concept and solves the same technology as Embodiment 1. Problem, because Embodiment 1 is mainly applied to sound transmission equipment, such as microphones, microphones and other equipment, in addition, Embodiment 2 of the present invention is mainly applied to speaker components 7 inside the speaker equipment, such as speakers, loudspeakers Etc. For this reason, if the technical solution adopted in the present invention is applied to the outer layer of the loudspeaker assembly 7, then the loudspeaker net with a composite waterproof structure is realized on the basis of the outer layer structure of the loudspeaker assembly 7.

[0058] The center of the anti-particle metal mesh 4 implemen...

Embodiment 3

[0061] Such as figure 1 , figure 2 , diagram 2-1 , Figure 4 As shown, on the basis of Embodiment 1 and Embodiment 2, Embodiment 3 of the present invention implements a manufacturing process of a speaker mesh with a composite waterproof structure, which mainly includes the following steps:

[0062] (1) First of all, the woven metal mesh or the metal sheet with a number of fine holes is used for processing and forming to form a particle-proof metal mesh 4 with a number of fine holes. The center of the particle-proof metal mesh 4 implemented along the A raised portion 41 is provided in the length direction of the metal mesh 4, and the raised portion 41 protrudes toward one side of the anti-particle metal mesh 4;

[0063] (2) Then, fix a layer of silica gel layer 3 on both sides of the anti-particle metal mesh 4, so that the silica gel layer 3 faces the internal components of the device (including but not limited to microphone components, speaker components), and the device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com