Multi-angle defect detection device

A defect detection, multi-angle technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of undetectable defects, low work efficiency, inconvenient use, etc., to facilitate detection and prevent dead spots in detection , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

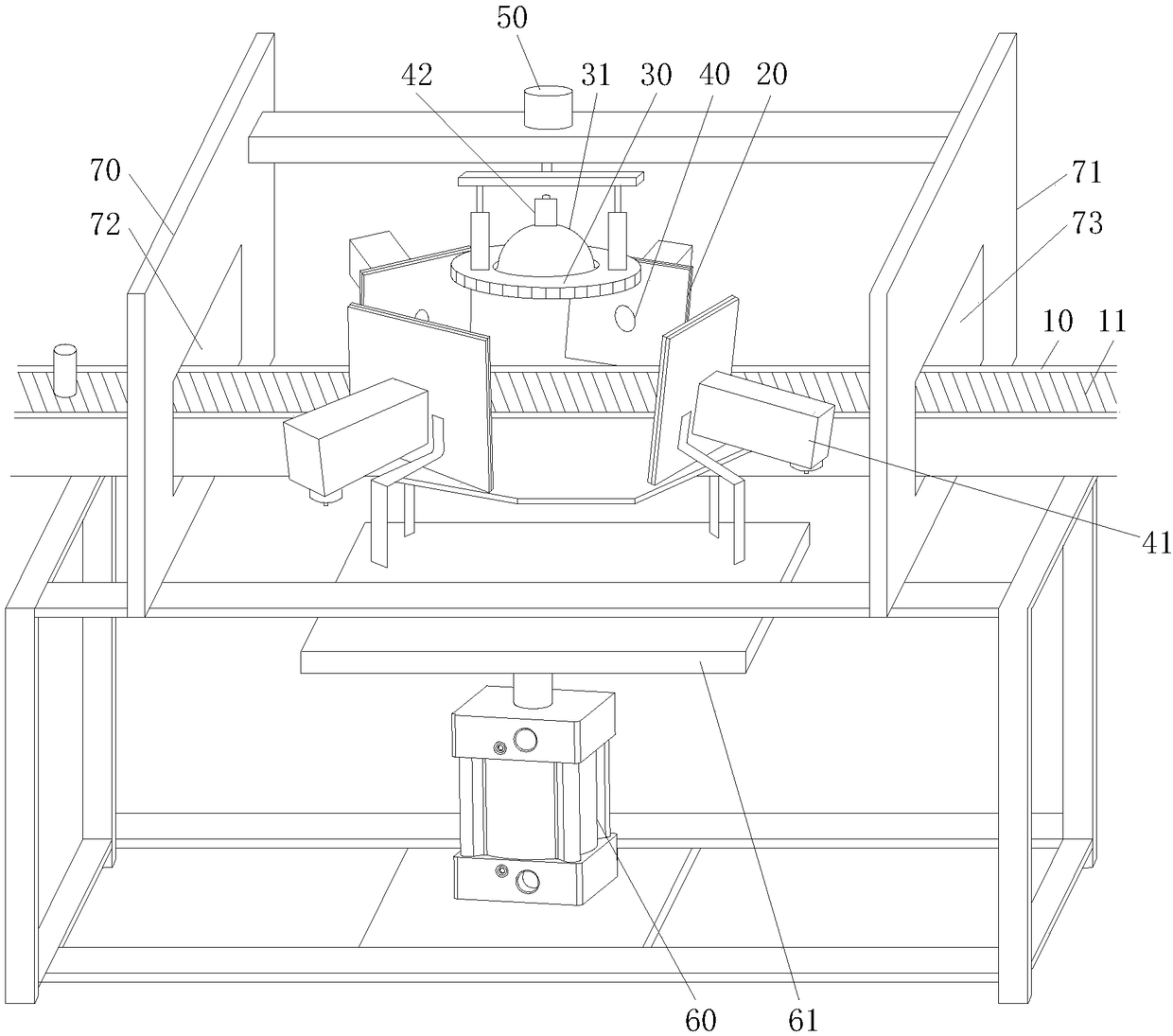

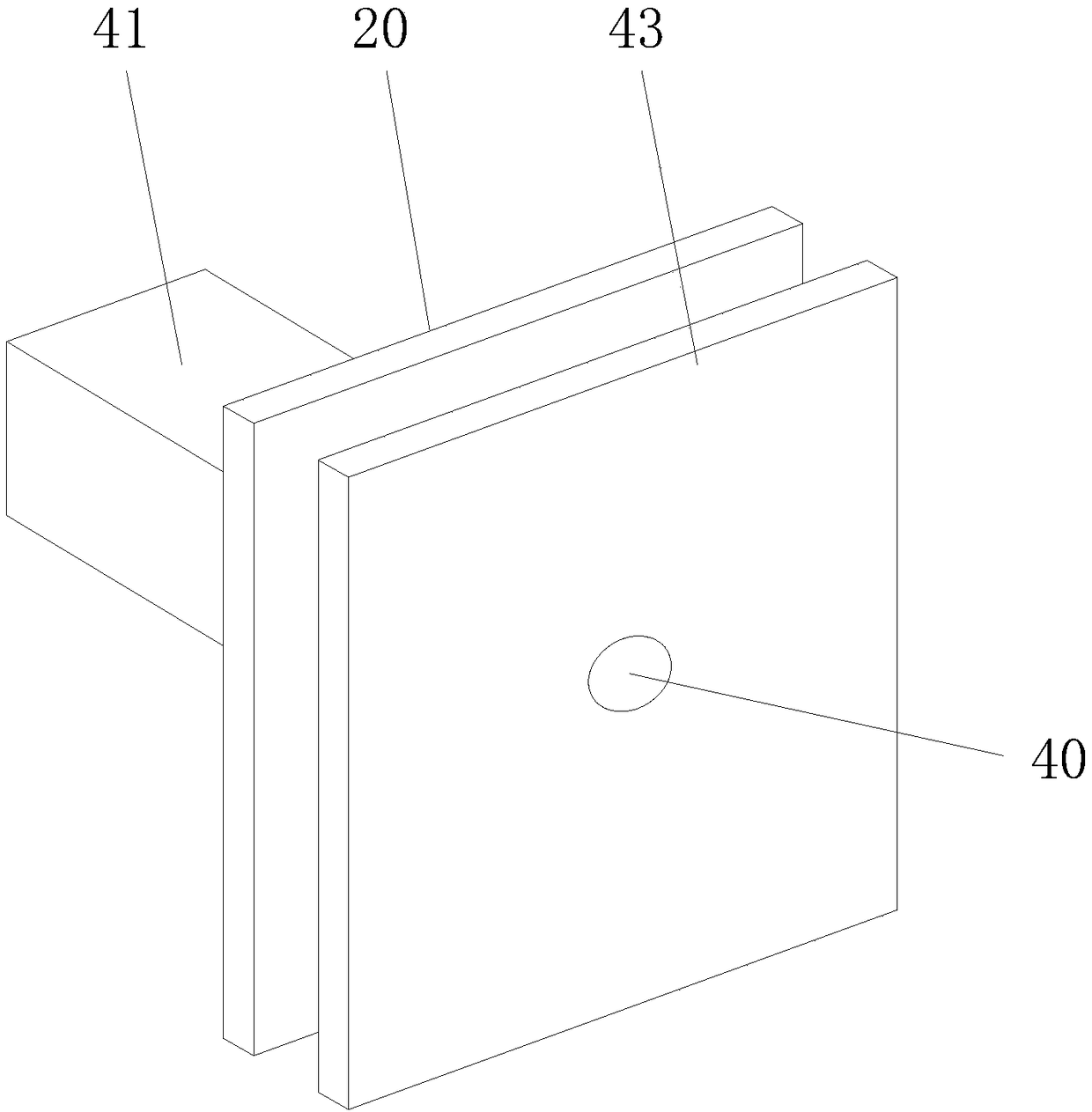

[0024] refer to Figure 1 ~ Figure 2 As shown, the present invention discloses a multi-angle defect detection device, which includes a platform 10, on which a conveyor belt 11 is arranged, and objects placed on the conveyor belt 11 can be transported. A detection area is set on the platform 10, a top light-emitting assembly is arranged on the upper side of the detection area, and a side light-emitting assembly is arranged around the detection area. The top light-emitting element is located on the upper side of the detection area to illuminate the top of the object to be tested. The side of the detection area is used to illuminate the side of the object to be inspected. In this embodiment, the conveyor belt 11 is externally connected to a driving source, and its movement is controlled by a controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com