Construction method of a rotating anti-collision traffic guardrail

A construction method and a rotating technology, applied in the directions of roads, buildings, road safety devices, etc., can solve the problems of slow installation speed, lack of installation construction methods and low installation quality of rotating anti-collision traffic guardrails, and achieve convenient and fast installation. , Improve labor efficiency, the effect of smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

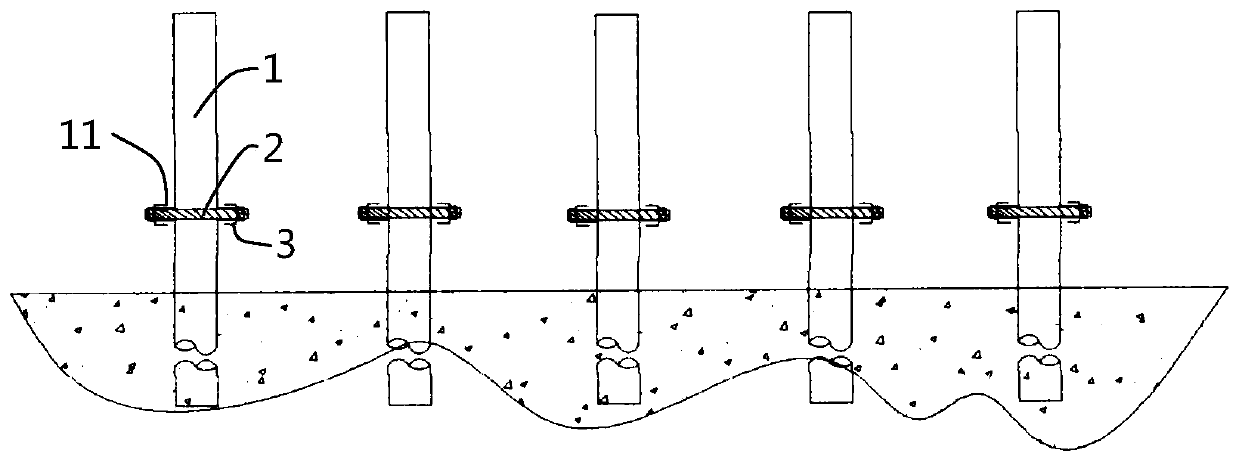

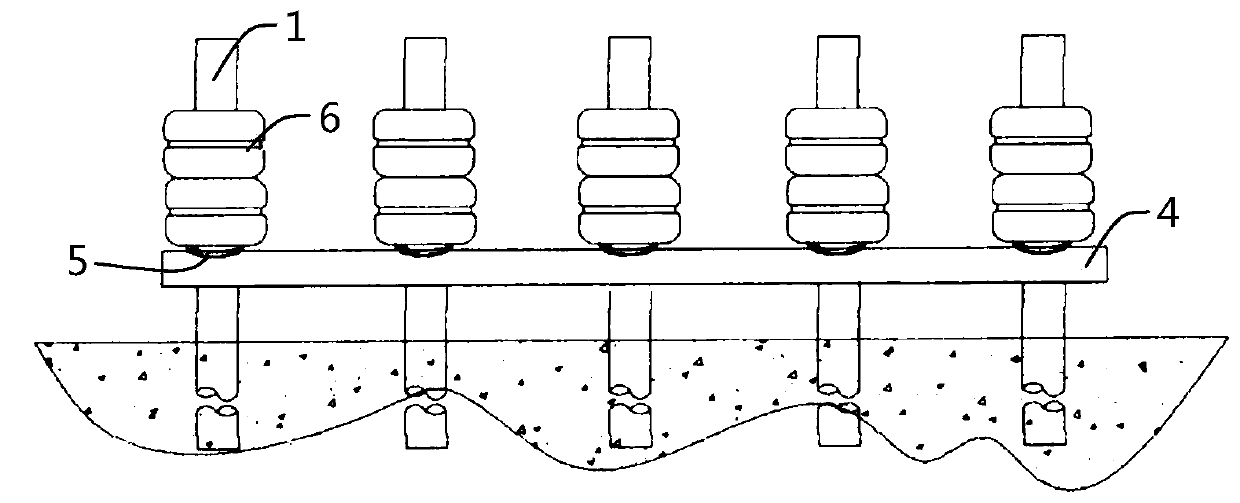

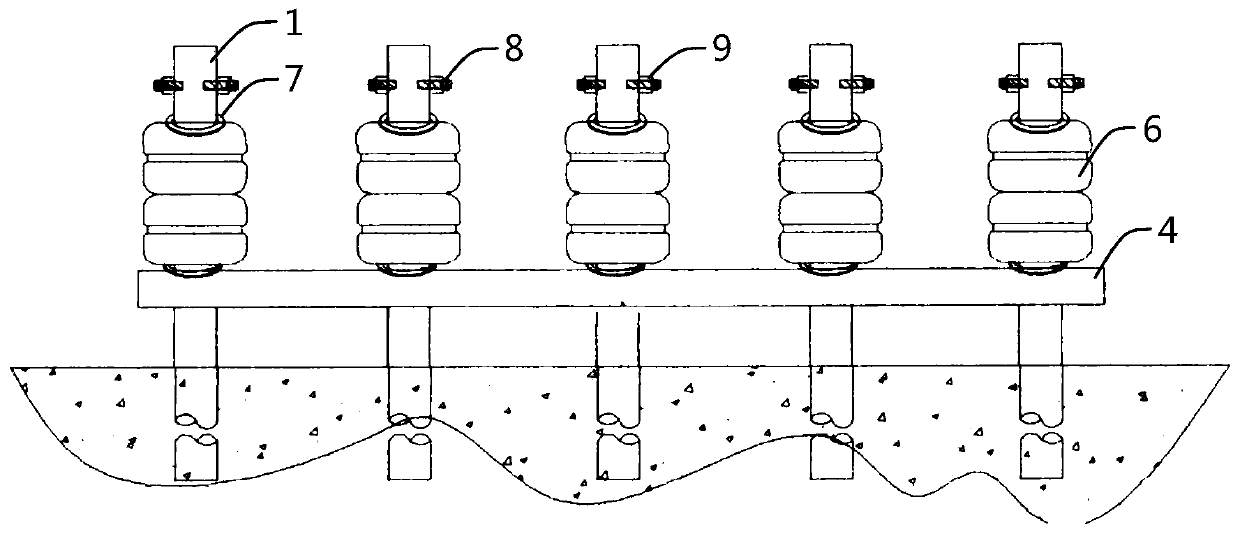

[0047] Please refer to Figure 1 to Figure 4 , the rotary anti-collision traffic guardrail of the present invention comprises a column 1, an elastic rotating body 6 sleeved on the column 1, an upper horizontal rail 10 and a lower horizontal rail 4 respectively arranged above and below the elastic rotating body 6, sleeved On the column 1 and arranged on the first turning circle 5 between the lower rail 4 and the elastic rotating body 6, the construction method of the rotating anti-collision traffic barrier comprises the following specific steps:

[0048] S101, marking line: use lime powder to mark the installation line according to a certain distance at the predetermined position on the road surface where the rotating anti-collision traffic guardrail is to be installed;

[0049] S102. Lower column: bury the column 1 at the calibrated installation position, the verticality deviation of the column 1 is 30', and set two rigid height marking poles on the vertical road surface on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com