Medium and trace element mineral nutritional soil and preparation method thereof

A technology of medium and trace elements and minerals, applied in fertilizer mixtures, organic fertilizers, potash fertilizers, etc., can solve problems such as unsatisfactory effects, achieve the effects of increasing yield and quality of agricultural products, improving air permeability, and preventing dead seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

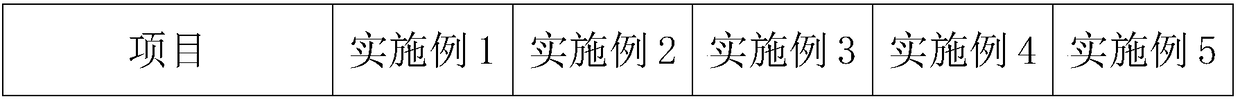

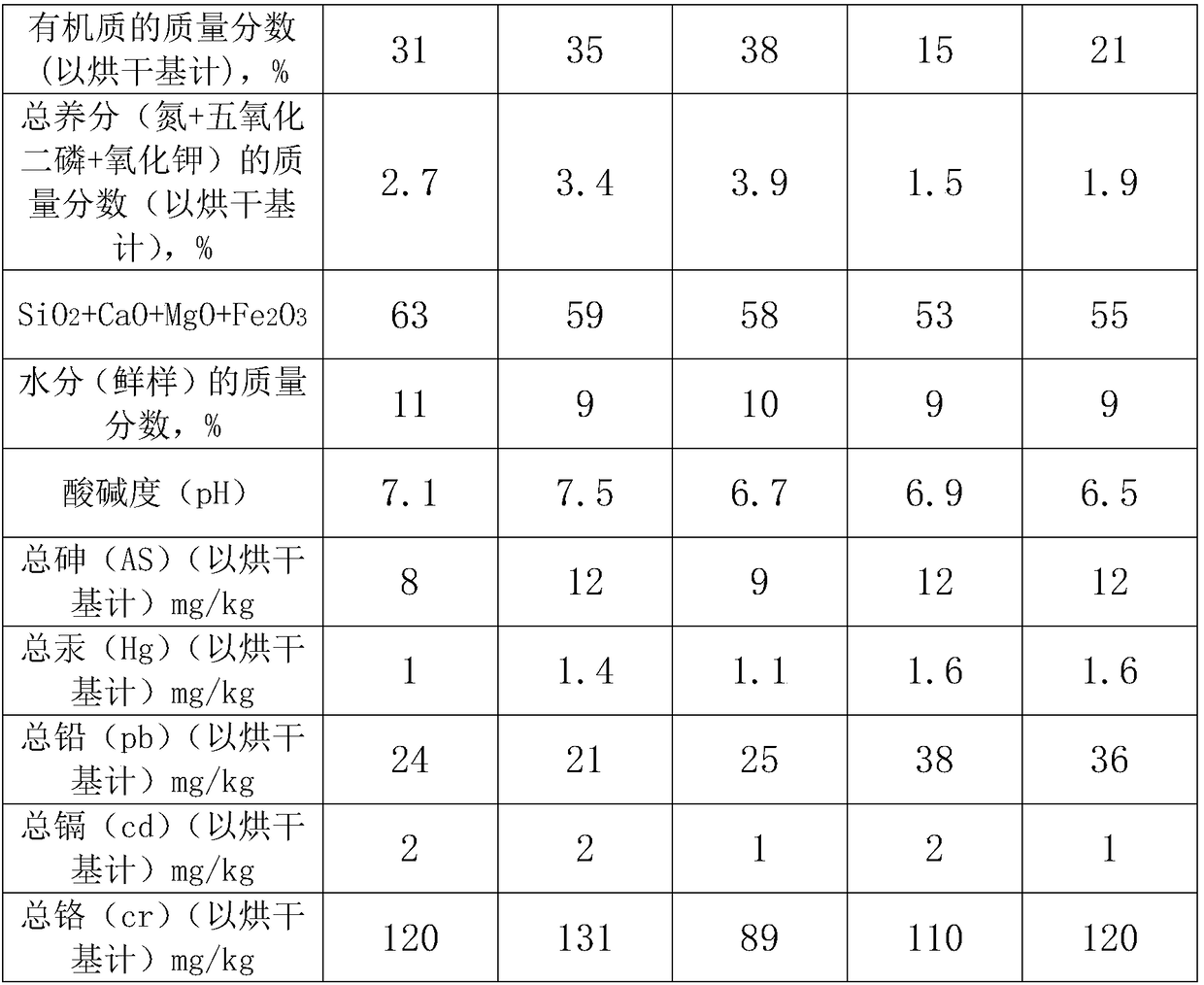

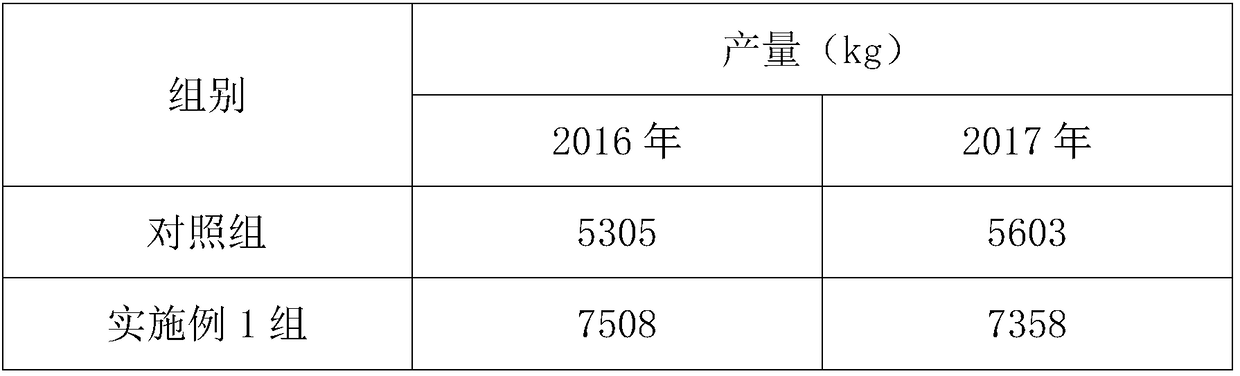

Examples

Embodiment 1

[0023] This example provides a medium and trace element mineral nutrient soil, which is mainly made of the following raw materials in parts by weight: 700 parts of attapulgite, 40 parts of humic acid, 67 parts of perlite, 30 parts of diatomite, and 50 parts of kaolin 80 parts, 80 parts of zeolite, 160 parts of vermiculite, 90 parts of sodium metaphosphate and 26 parts of plant ash.

[0024] Its preparation method comprises the following steps:

[0025] S1, pulverize attapulgite, perlite, kaolin, zeolite and vermiculite to 200 mesh respectively;

[0026] S2. Weighing the crushed attapulgite and putting it into 6mol / L NaOH solution, ultrasonically oscillating for 35 minutes at 35°C, filtering, and rinsing with distilled water 3 times to obtain alkali-treated attapulgite;

[0027] S3. Put the alkali-treated attapulgite into the reaction kettle, raise the temperature to 700° C., and keep it for 120 minutes. After the temperature drops to room temperature, take out the attapulgite...

Embodiment 2

[0031] This example provides a medium and trace element mineral nutrient soil, which is mainly made of the following raw materials in parts by weight: 200 parts of attapulgite, 130 parts of humic acid, 20 parts of perlite, 60 parts of diatomite, and 26 parts of kaolin 140 parts of zeolite, 30 parts of vermiculite, 40 parts of sodium metaphosphate and 50 parts of plant ash.

[0032] Its preparation method comprises the following steps:

[0033] S1, pulverize attapulgite, perlite, kaolin, zeolite and vermiculite to 100 mesh respectively;

[0034] S2. Weighing the crushed attapulgite and putting it into 3mol / L NaOH solution, ultrasonically oscillating at 43°C for 10 minutes, filtering, and rinsing with distilled water for 5 times to obtain alkali-treated attapulgite;

[0035] S3. Put the alkali-treated attapulgite into the reaction kettle, raise the temperature to 500° C., and keep it for 30 minutes. After the temperature drops to room temperature, take out the attapulgite to ob...

Embodiment 3

[0039] This example provides a medium and trace element mineral nutrient soil, which is mainly made of the following raw materials in parts by weight: 450 parts of attapulgite, 79 parts of humic acid, 41 parts of perlite, 47 parts of diatomite, and 43 parts of kaolin 93 parts of zeolite, 88 parts of vermiculite, 69 parts of sodium metaphosphate and 39 parts of plant ash.

[0040] Its preparation method comprises the following steps:

[0041] S1, pulverize attapulgite, perlite, kaolin, zeolite and vermiculite to 160 mesh respectively;

[0042] S2. Weighing the pulverized attapulgite and putting it into 5mol / L NaOH solution, ultrasonically oscillating at 41°C for 20 minutes, filtering, and rinsing with distilled water 4 times to obtain alkali-treated attapulgite;

[0043] S3. Put the alkali-treated attapulgite into the reaction kettle, raise the temperature to 600° C., and keep it for 60 minutes. After the temperature drops to room temperature, take out the attapulgite to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com