Cigarette dark packing plastic film with function of aroma compensating

A technology of plastic film and dark color, which is applied in the field of packaging and cigarette dark packaging plastic film, can solve the problem of single transparent packaging plastic film, achieve the effect of improving the level of error prevention, practical function, and solving the effect of easy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

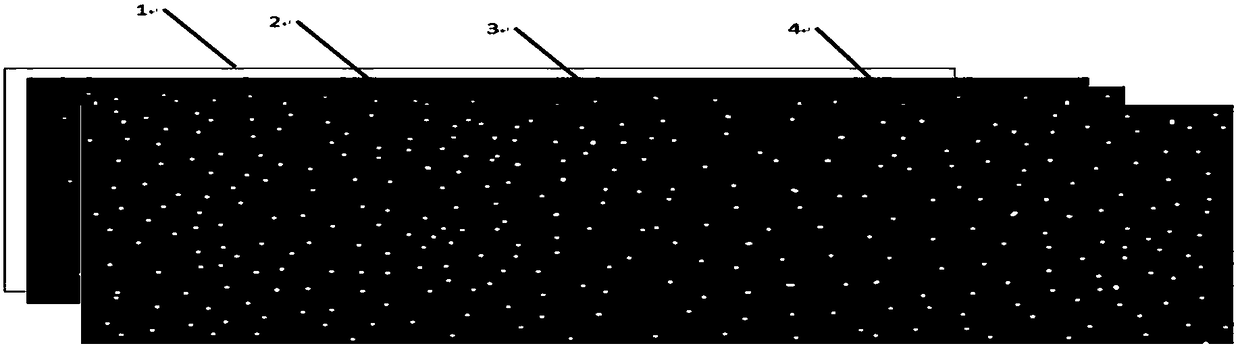

[0023] Embodiment one: if figure 1 As shown, a dark plastic film for cigarettes with an aroma compensation function includes a plastic film 1 and a printing ink 2. The ink is composed of a colorant, a filler and an auxiliary agent. In order to prevent the colorant from dissolving in water, the colorant A water-insoluble pigment is used to spray and atomize the flavoring sugar material suitable for the aroma characteristics of the cigarette brand in the filler. In the process of printing with ink, the plastic film is pressed with concave-convex dense dots, so that the plastic film has a texture of dense three-dimensional dots, which is easier for the sugar to adhere to and maintains the aroma of the plastic film.

Embodiment 2

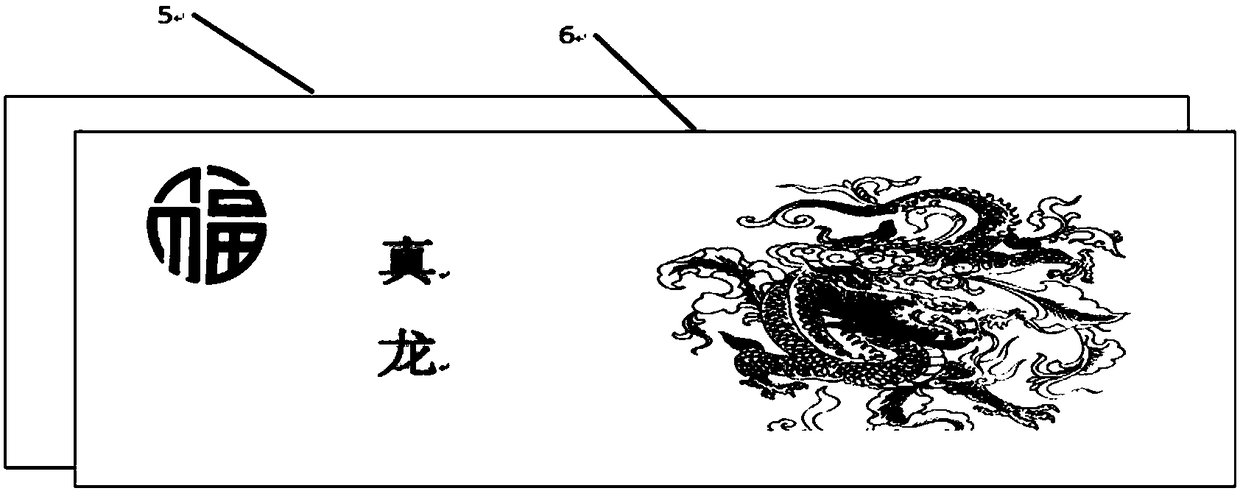

[0024] Embodiment two: if figure 2 As shown, a dark plastic film for cigarettes with aroma compensation function, including plastic film 5, printing ink 6, the ink is composed of colorant, filler and auxiliary agent, adding flavoring sugar material with cigarette aroma compensation function to the ink , use ink to print text or patterns on plastic film.

Embodiment 3

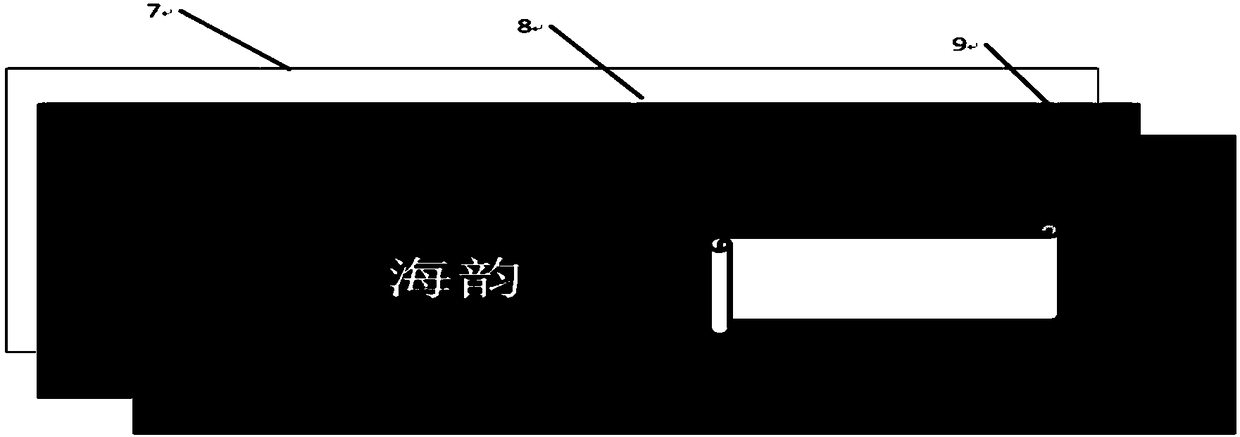

[0025] Embodiment three: as image 3 As shown, a dark plastic film for cigarettes with aroma compensation function, including plastic film 7, printing ink 8, the ink is composed of colorants, fillers and auxiliary agents, and sugar with aroma compensation function of cigarette brands is added to the ink First, use ink to print on the plastic film, and then use ink of different colors to print text or patterns on the plastic film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com