Vehicle liquid crystal screen bracket forming mold

A technology for molding molds and LCD screens, which can be applied to household appliances, other household appliances, household components, etc., can solve problems such as difficulty, poor stability, and protracted cycle of product molding, and achieve high yield and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

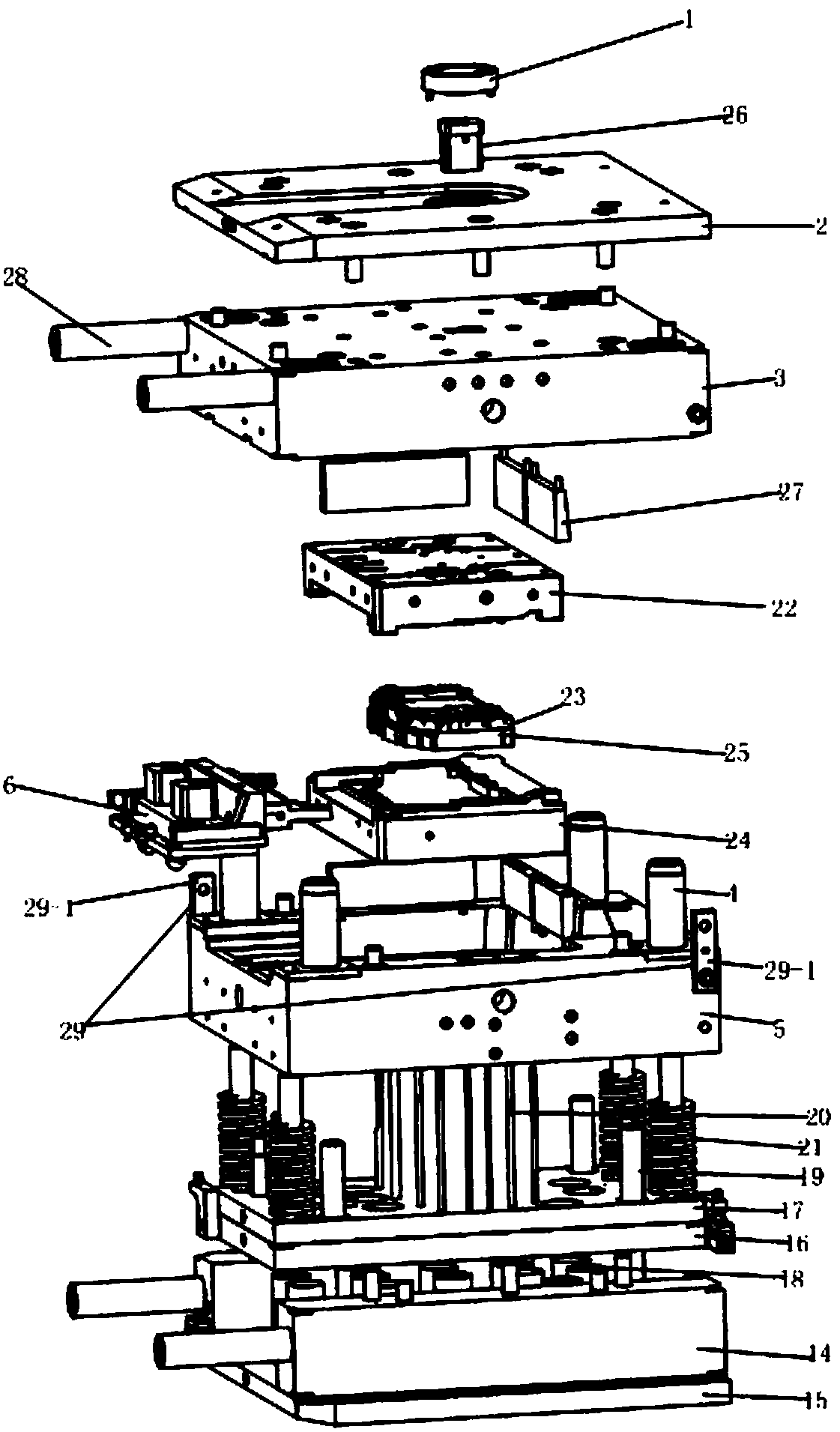

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

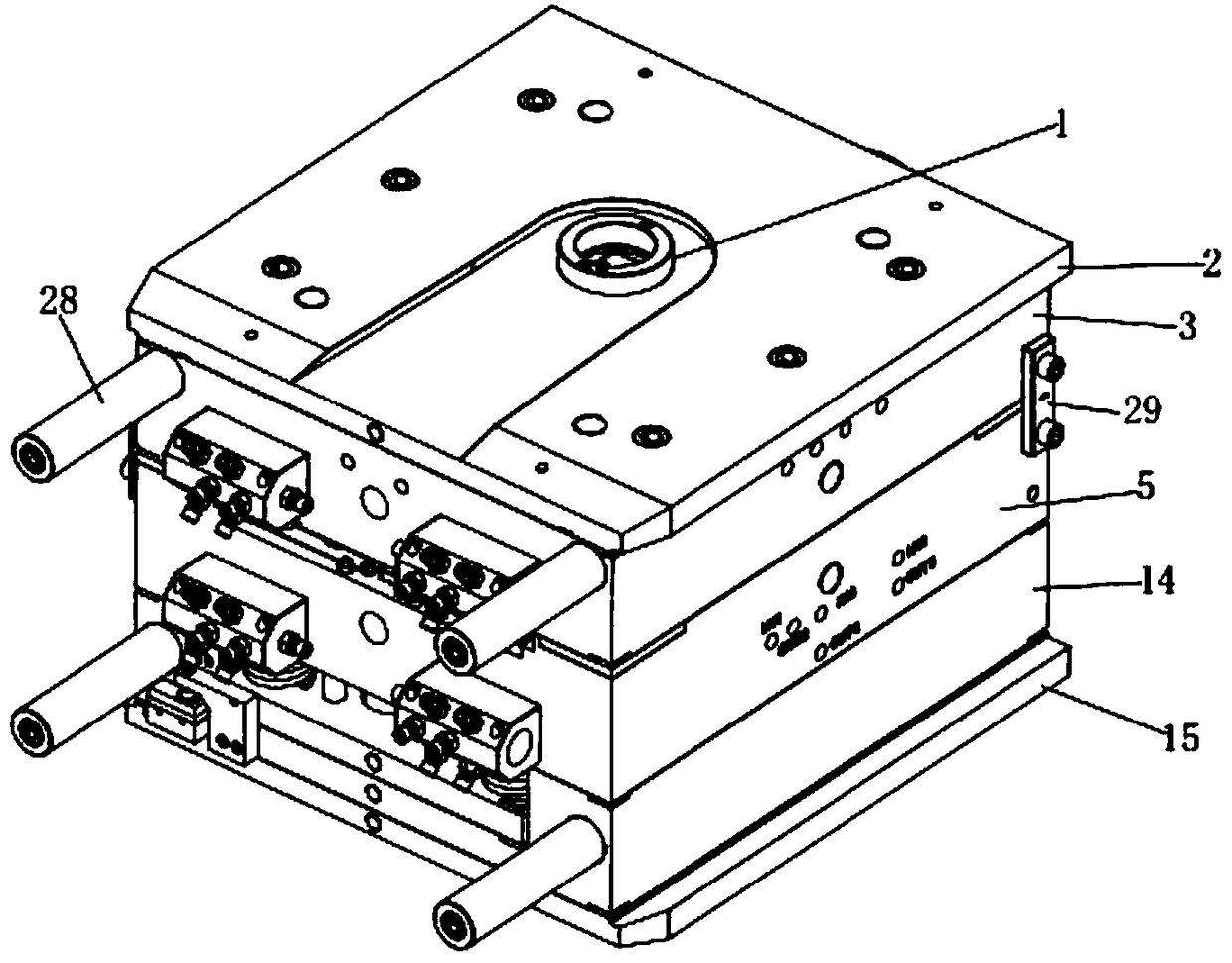

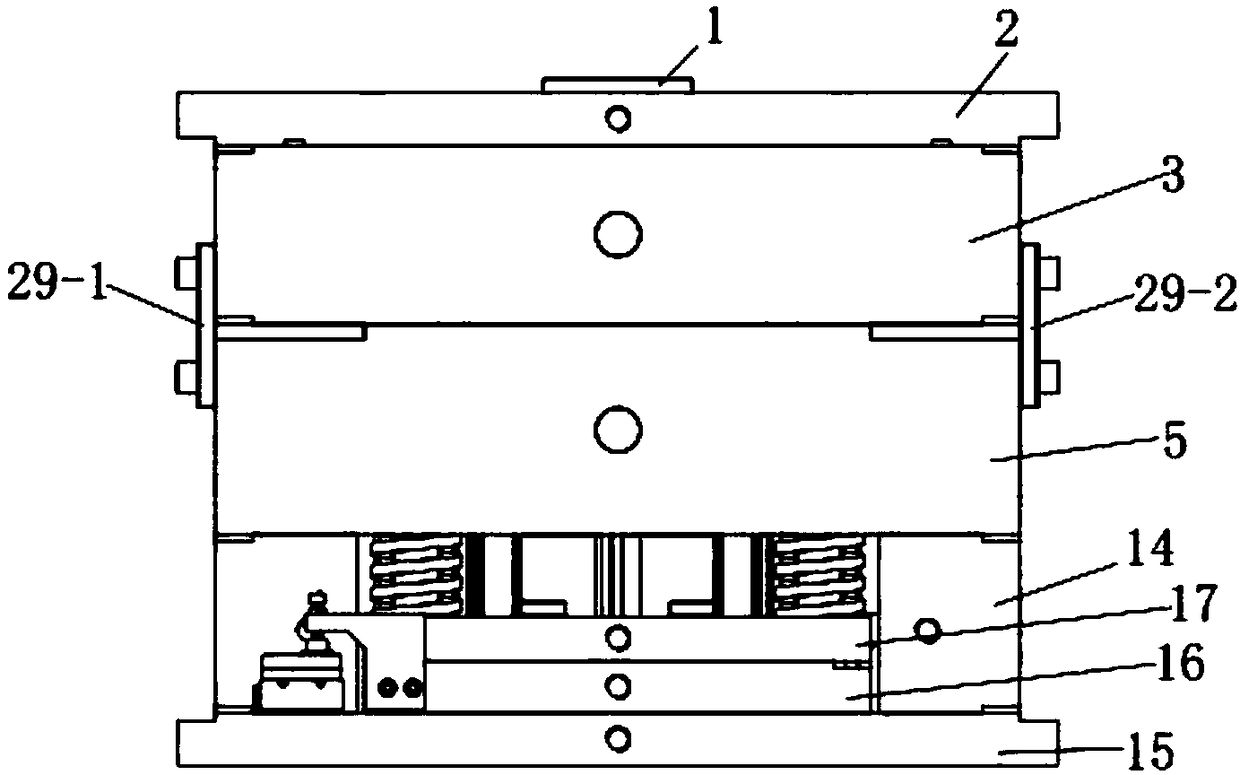

[0020] Such as Figure 1-4 Shown, a kind of automotive liquid crystal screen bracket forming mold comprises positioning ring 1, top plate 2, front template 3, guide column 4 and rear template 5, and described positioning ring 1 is fixed on the top plate 2, and described top plate 2 is installed on the front On the template 3, the front template 3 is connected with the rear template 5 through the guide column 4, the rear template 5 is provided with a rear mold slider mechanism 6, and the rear mold slider mechanism 6 includes a first wear block 7 , slider seat 8, second wear block 9, inclined guide post 10, pressure block 11, third wear block 12 and insert 13, said insert 13 is fixed on the right end of slide block seat 8, and said slide bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com