Processing device of ceramic product

A processing device and product technology, which is applied in the field of ceramic processing, can solve the problems that squatting pans and support tables cannot be glazed, and the quality of squatting pans cannot be glazed, so as to improve the quality of glazing, reduce labor intensity, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

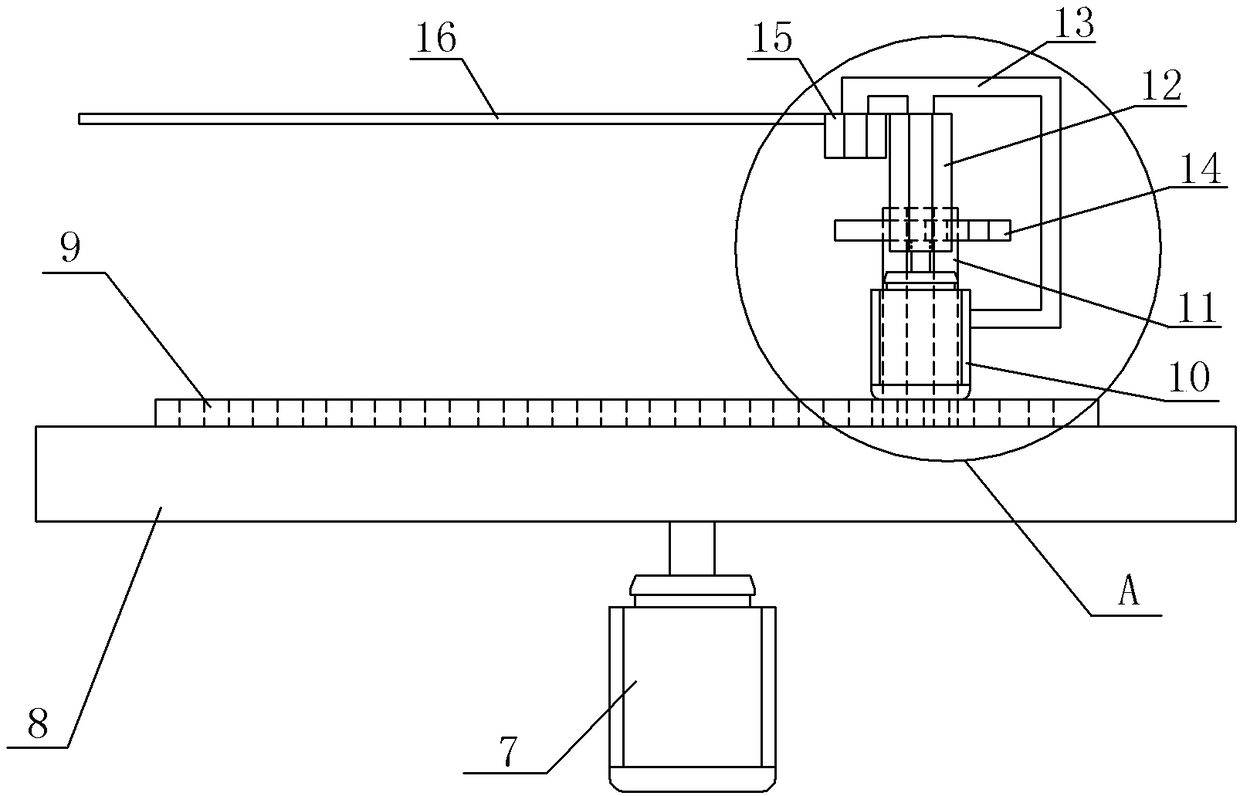

[0019] The reference signs in the drawings of the description include: conveyor belt 1, support platform 2, squatting pan 3, resisting block 4, water inlet hole 5, intercepting block 6, No. 1 servo motor 7, support plate 8, rack 9, No. 2 Servo motor 10, No. 1 gear lever 11, No. 2 gear lever 12, support frame 13, incomplete gear 14, gear 15, support rod 16.

[0020] Such as figure 1 The ceramic product processing device shown includes a conveyor belt 1, a transfer mechanism and a support table 2 from left to right. The conveyor belt 1 is set on the frame and transmits the squatting pan 3 from the back to the front. The left side of the conveyor belt 1 is fixed with a resisting block 4 for resisting the squatting pan 3, wherein the squatting pan 3 is provided with two left and right water inlet holes 5 and A drain hole below. The transfer mechanism is arranged on the upper right of the conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com