A tooling fixture for auto parts

A technology for auto parts and fixtures, applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve problems such as poor device safety and operator pinch injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

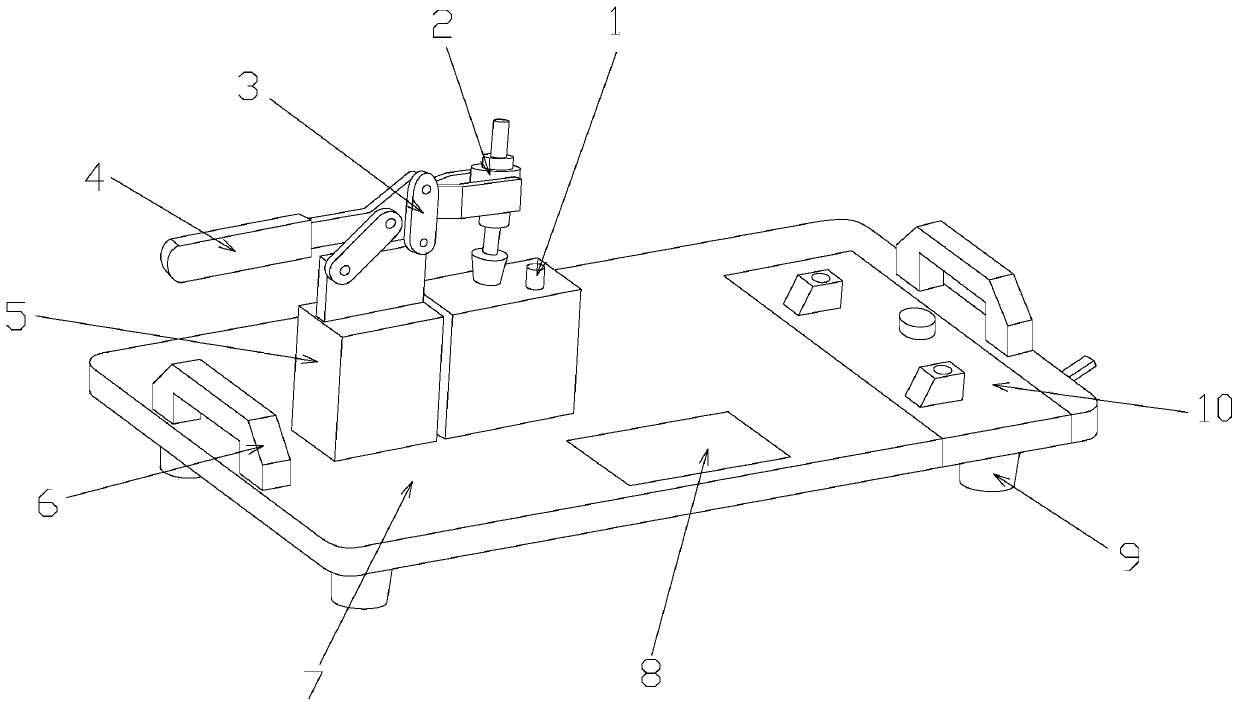

[0021] like Figure 1-Figure 5As shown, the present invention provides a tooling fixture for auto parts, the structure of which includes a part positioning buckle 1, a clamping rubber column 2, a crank connection block 3, an anti-slip operating handle 4, a clamp support seat 5, an operating handle 6, a zero Component processing table 7, fixture nameplate 8, anti-slip support feet 9, adjustable clamping device 10, said anti-slip support feet 9 are threadedly connected to the four corners of the bottom surface of the parts processing table 7 and are perpendicular to the parts processing table 7, so The operating handle 6 is bolted to the left and right ends of the upper surface of the parts processing table 7, the fixture nameplate 8 is fixed to the middle of the upper surface of the parts processing table 7 by rivets, and the fixture support seat 5 is provided with two parts welded to the parts respectively. The left end of the upper surface of the processing table 7, the anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com