Full-automatic powder grinding machine

A fully automatic, milling machine technology, applied in the field of food processing, can solve the problems of large manpower, inconvenience, consumption, etc., and achieve the effect of research assistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

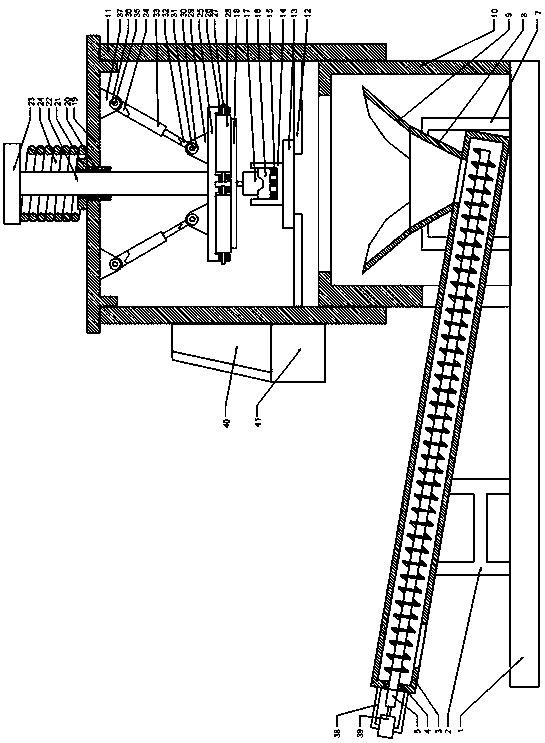

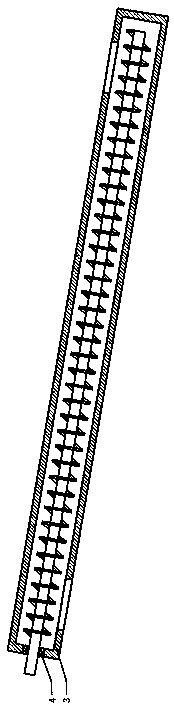

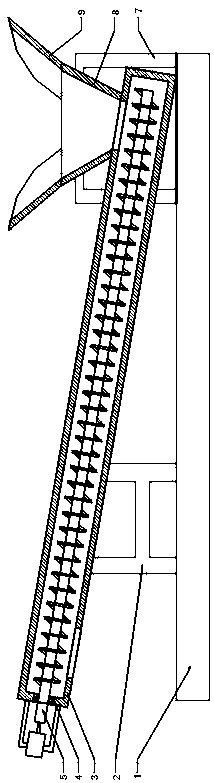

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a fully automatic pulverizer includes a chassis 1, the chassis 1 is located above the ground, and a collection mechanism is arranged above the chassis 1, and the collection mechanism is fixedly connected by a powder transmission installation frame 2 located above the chassis 1. , the powder conveying pipe 3 installed on the powder conveying installation frame 2, the conveying screw fixed bearing 4 installed above the powder conveying pipe 3, the conveying screw 5 inserted in the conveying screw fixed bearing 4, located above the powder conveying pipe 3 and The powder collection funnel support 6 fixedly connected to the chassis 1, the powder collection funnel mounting frame 7 fixedly connected to the powder collection funnel support 6 inside the powder collection funnel support 6, the powder collection funnel 8 fixedly connected to the powder collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com