Pneumatic thin film performing mechanism with built-in type anti-rotating device

A technology for actuators and pneumatic membranes, applied in valve devices, engine components, valve operation/release devices, etc., can solve the problems of diaphragm rotation damage, spring instability, linearity of regulating valves, and non-compliance of hysteresis. Achieve the effects of avoiding cracking and damage, preventing the rotation of the push rod, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

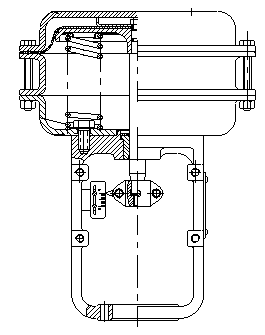

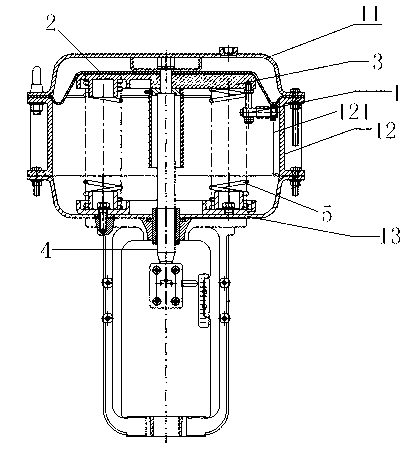

[0041] see image 3, the pneumatic membrane actuator with a built-in anti-rotation device in this embodiment is specifically a positive-acting high-thrust pneumatic membrane actuator with a built-in anti-rotation device, which includes a membrane cover assembly, a diaphragm 2, a tray 3, The elastic element and push rod 4, wherein the membrane cover assembly includes an upper membrane cover 11, a connecting pipe 12 and a lower membrane cover 13 connected in sequence, and the upper membrane cover 11, the connecting pipe 12 and the lower membrane cover 13 form the membrane cavity of the actuator, and the diaphragm 2 is fixed inside the membrane cover assembly, specifically between the upper membrane cover 11 and the connecting pipe 12, and the tray 3 is fixed on the diaphragm 2. Specifically, in this embodiment, the elastic elements are two symmetrically arranged springs 5, each The two ends of the root spring are respectively connected with the lower membrane cover 13 and the tr...

Embodiment 2

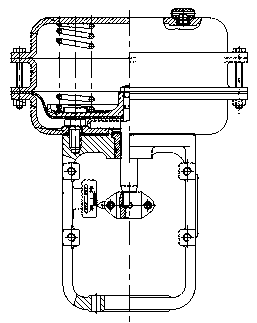

[0050] see Figure 9 , The difference between this embodiment and Embodiment 1 is that the above-mentioned built-in anti-rotation device is applied to the reaction large-thrust pneumatic film actuator, specifically, the diaphragm is fixed between the lower diaphragm cover and the connecting pipe, and the tray and the diaphragm are fixed. Connection, the tray is fixedly connected with the push rod, the anti-rotation screw on the vertical part of the built-in anti-rotation device is fixedly connected to the tray, and the bearing on the anti-rotation connecting rod on the horizontal part snaps into the anti-rotation guide groove set in the connecting pipe bottom end.

[0051] from image 3 The first embodiment shown and Figure 9 It can be seen from the second embodiment that there is a built-in anti-rotation device in the membrane cavity of the pneumatic film actuator, and the built-in anti-rotation device is fixed on the tray, and the rolling bearing at the horizontal part is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com