Endurance test control system and method of seat motor

A technology of durability test and control system, applied in the direction of motor generator test, measurement of electricity, measurement of electrical variables, etc., can solve problems such as differences in durability test parameters and differences in durability test conditions, and achieve the effect of convenient test process and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

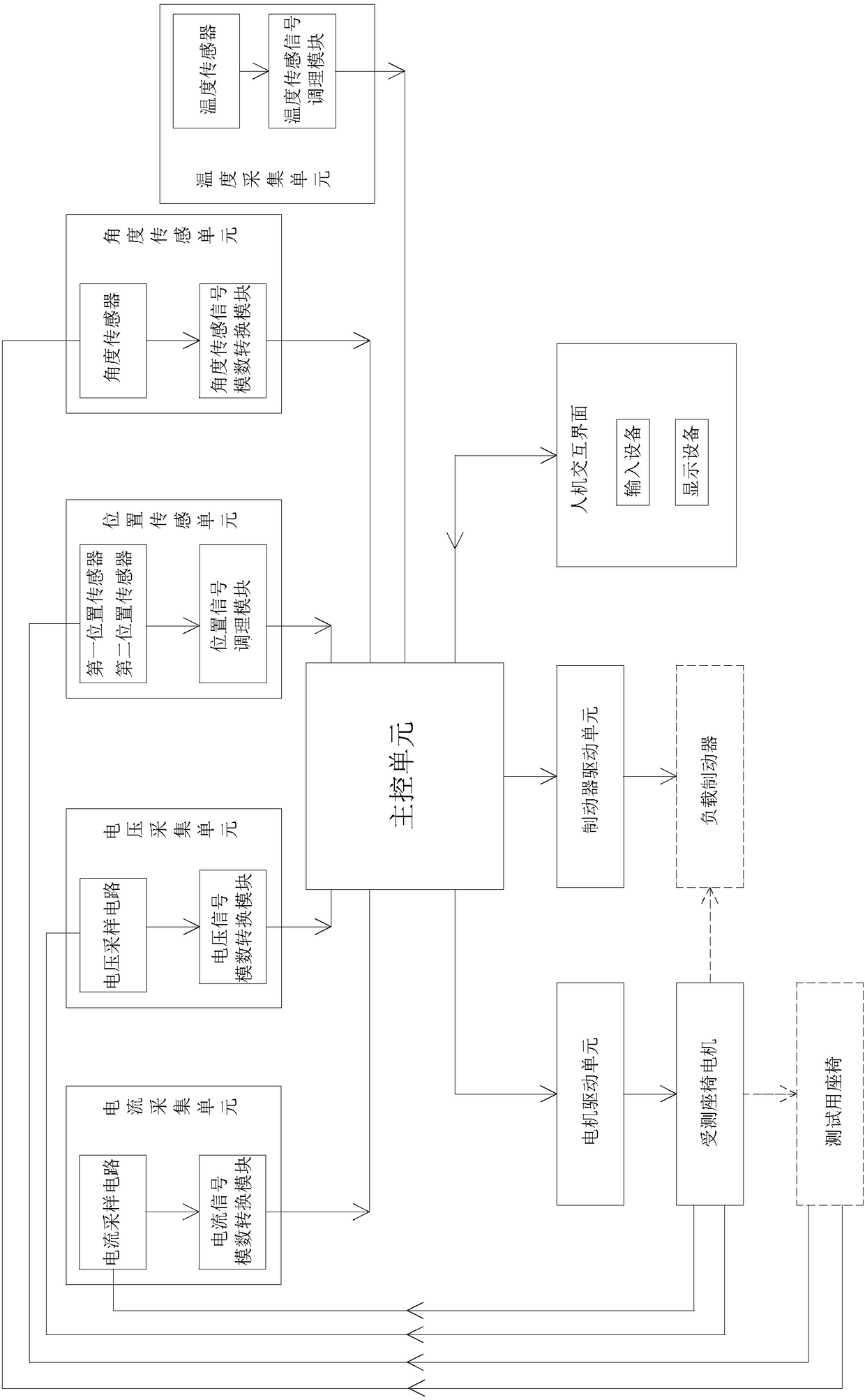

[0101] The seat motor durability test control system of the present invention can also be provided with a voltage acquisition unit and a temperature acquisition unit, the main control unit is electrically connected with the voltage acquisition unit and the temperature acquisition unit respectively, and the voltage acquisition unit is used to collect the temperature of the seat motor under test. Working voltage and can send the collected working voltage to the main control unit in real time, the temperature collection unit is used to collect the ambient temperature of the environment where the seat motor durability test control system is located and can send the collected ambient temperature to the main control unit in real time; The main control unit has a memory, and the main control unit saves the parameter setting instructions received by the main control unit, the operating current collected by the current acquisition unit, the operating voltage collected by the voltage acqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com