Construction method for performing humidification and ultra-high energy level treatment on collapsible loess foundation with height of 25m or more

A technology of collapsible loess and construction methods, which is applied in infrastructure engineering, soil protection, construction, etc., and can solve problems such as high loess strength, inability to construct, and reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

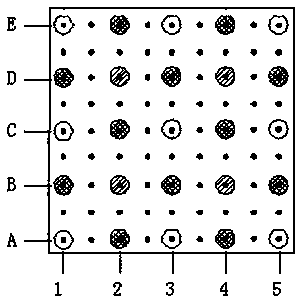

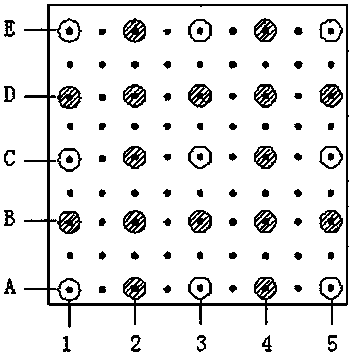

Image

Examples

example 1

[0217] The landform type of the proposed project site is loess beam, and the thickness of the collapsible soil layer on the site is 25m, which belongs to the self-weight collapsible site of level II-III. Three test ramming schemes were compared on site:

[0218] 1. General situation of the tamping test site:

[0219] The building grade is Class C, and the design requires that the depth of collapsibility elimination should be 12m below the ramming surface, and the remaining collapsibility should not exceed 200mm.

[0220] According to the calculation of exploration and exploration wells in each test ramming area, under the condition that the remaining collapsibility is not greater than 200mm:

[0221] In area I of test ramming, the humidification depth is 9m;

[0222] Test ramming area Ⅱ, the humidification depth is 11m;

[0223] The calculated humidification depths of the three exploratory wells in the test ramming area Ⅲ are 16m, 11m, and 9m respectively. When the test is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com