Steel seal printing device for packaging box

A packaging box and stamping technology, applied in the field of stamping device, can solve problems such as pin and die wear, influence on inspection, complex stamping mechanism, etc., to avoid device loss, avoid prefix offset, and ensure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

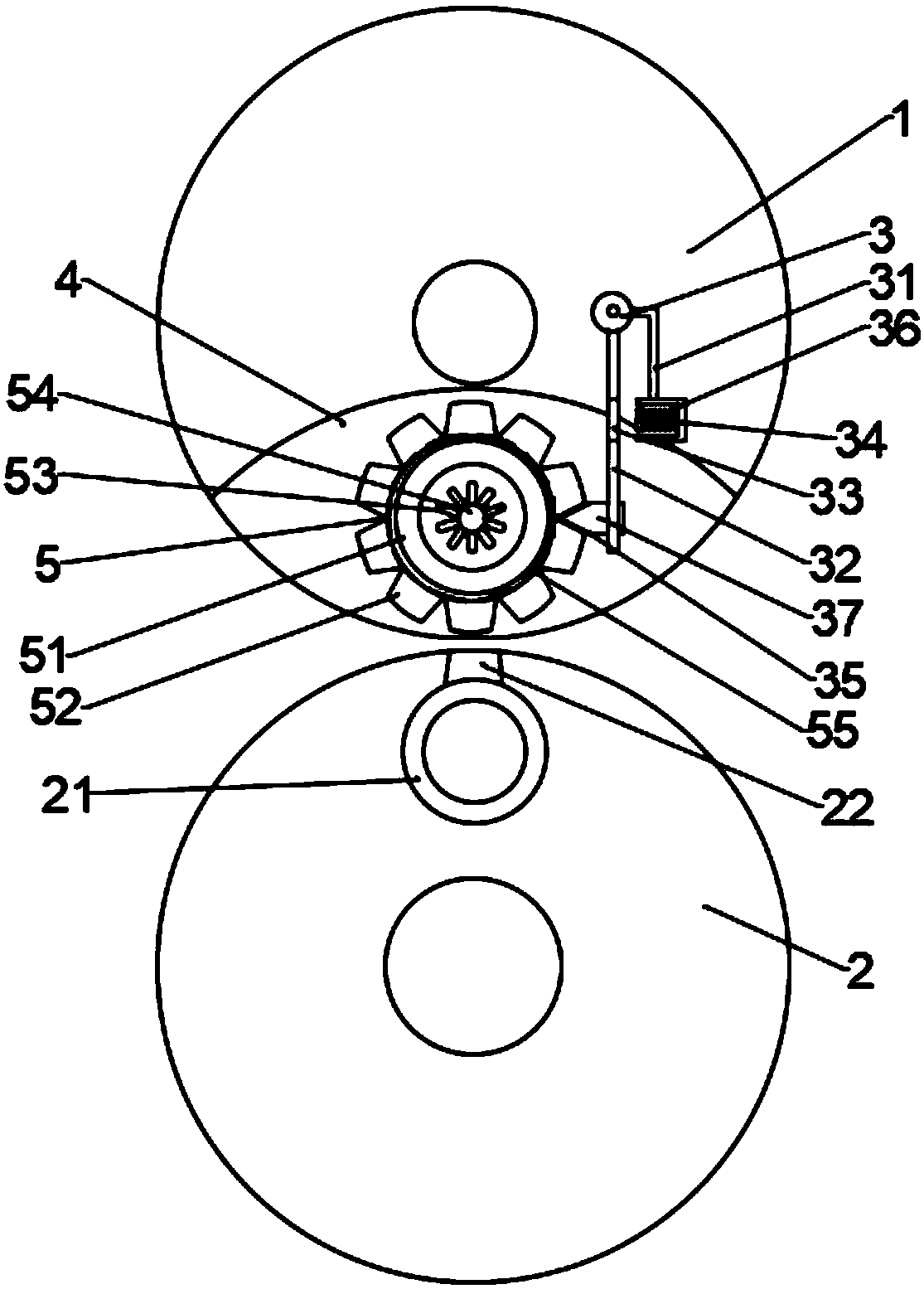

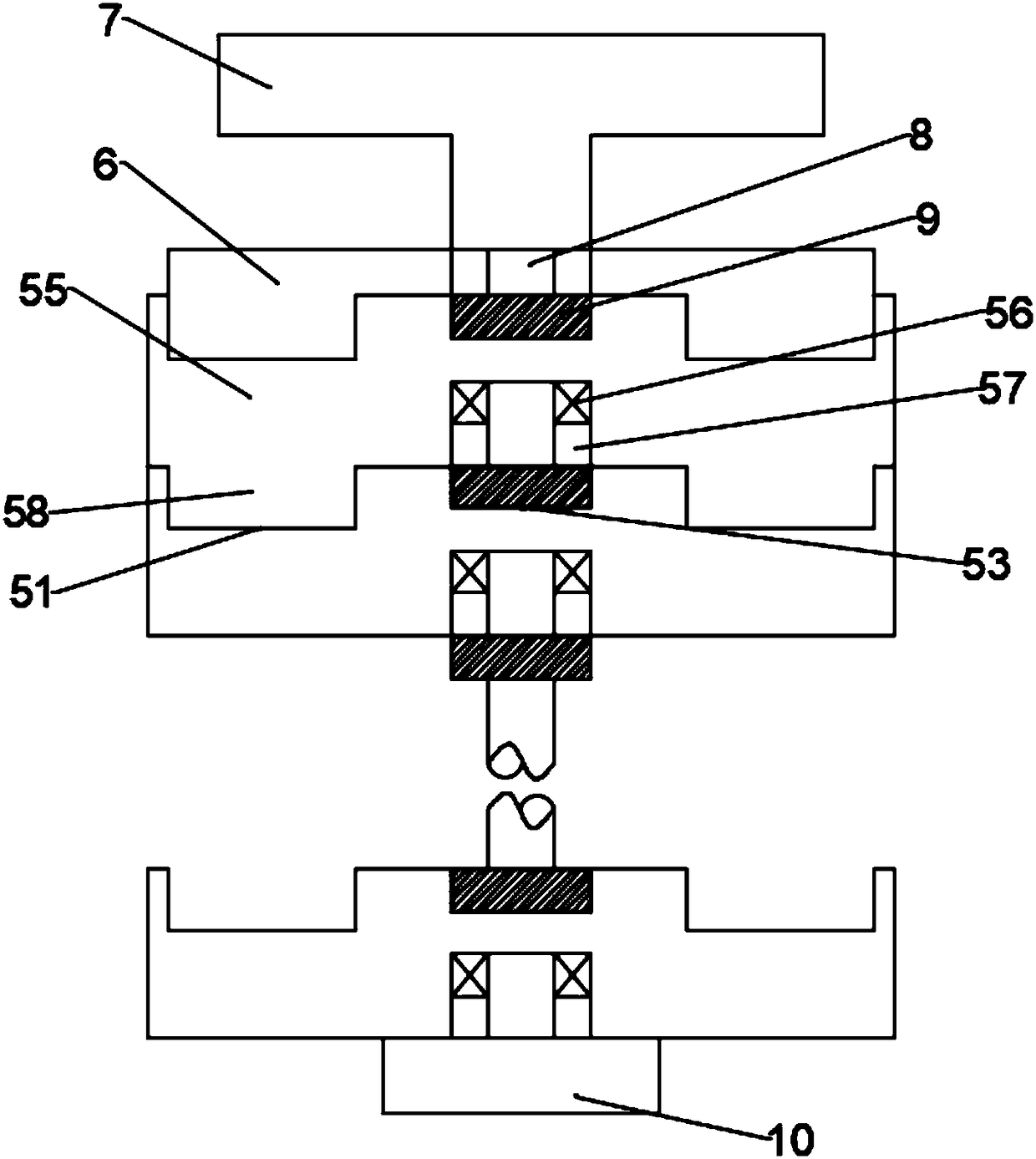

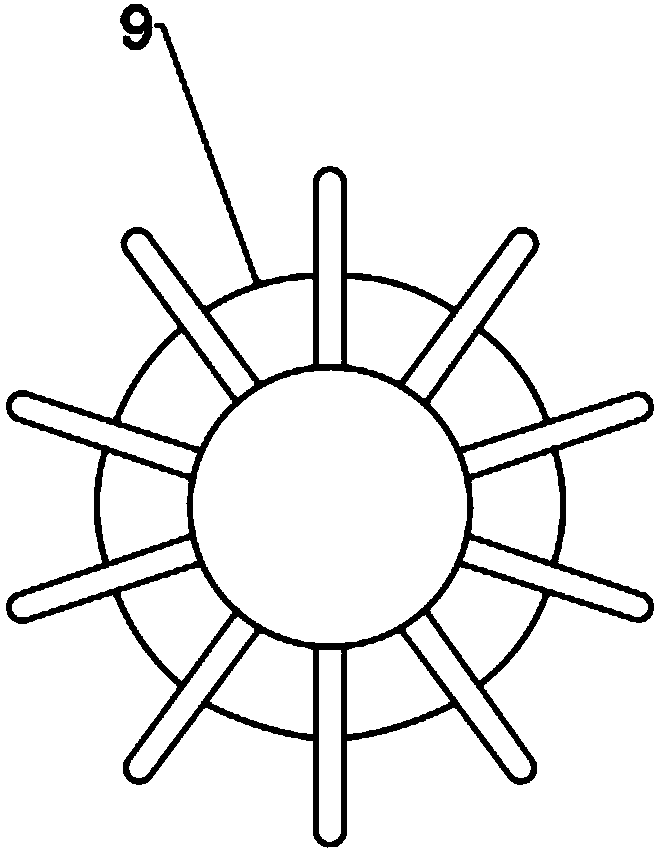

[0022] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a stamping device for packaging boxes, including a stamp base 1, a stamp base 2 and a handle 7, characterized in that: the bottom of the stamp base 1 is provided with a rugby-shaped stamp cavity 4, The middle of the printing cavity 4 is provided with a disk-type stamp group 5, and the right end of the disk-type stamp group 5 is provided with a magnetic lock mechanism 3, and the printing seat 2 is installed on the bottom of the stamp seat 1, and the inside of the printing seat 2 The top is provided with an inner column 21, and the top of the inner column 21 is provided with a protruding tooth 22, the protruding tooth 22 is 1mm-2mm higher than the surface of the printing seat 2, and one end of the disc stamp group 5 is provided with a handle 7, so The draw handle 7 is connected with a locking shaft 8, and disc-shaped bayonet pins 9 are installed at equal intervals on the locking shaft 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com