Gold nanowires with mixed optional arrangement of various close-packed structures and their preparation method and application

A gold nanowire and close-packed technology, applied in the field of nanoscience, can solve the problems of easy phase transition, limited method of gold nanocrystal, poor stability of gold nanocrystal, etc., and achieve simple preparation method, excellent catalytic performance and enhanced catalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) In the air, put 1.25*10 -2 mmol tetrachloroauric acid and 5*10 -2 Add mmol copper chloride to 6mL oleylamine, stir and mix well.

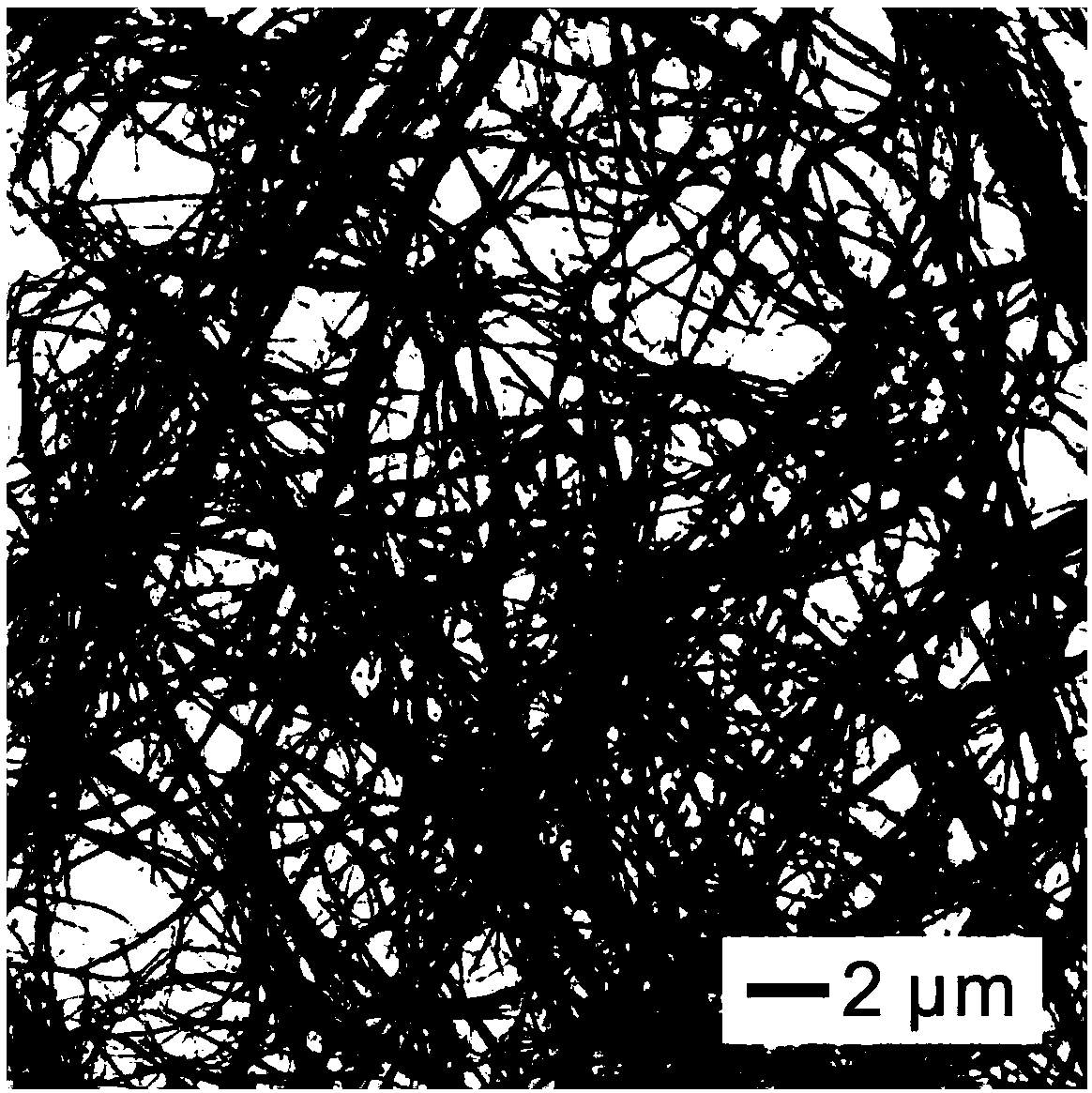

[0062] (2) In the air, place the solution in step (1) in an oil bath at 180° C. and stir, react for 2 minutes and 30 seconds, centrifuge, discard the supernatant, and wash the bottom precipitate (n-hexane: ethanol=1 : 1, three times) to obtain gold nanowires with a variety of close-packed structures mixed and arranged randomly. Its transmission electron microscope pictures are shown in figure 1 middle.

Embodiment 2

[0064] (1) Set 1.25*10 -2 mmol tetrachloroauric acid and 5*10 -2 Add mmol copper chloride to 6mL oleylamine, stir and mix well.

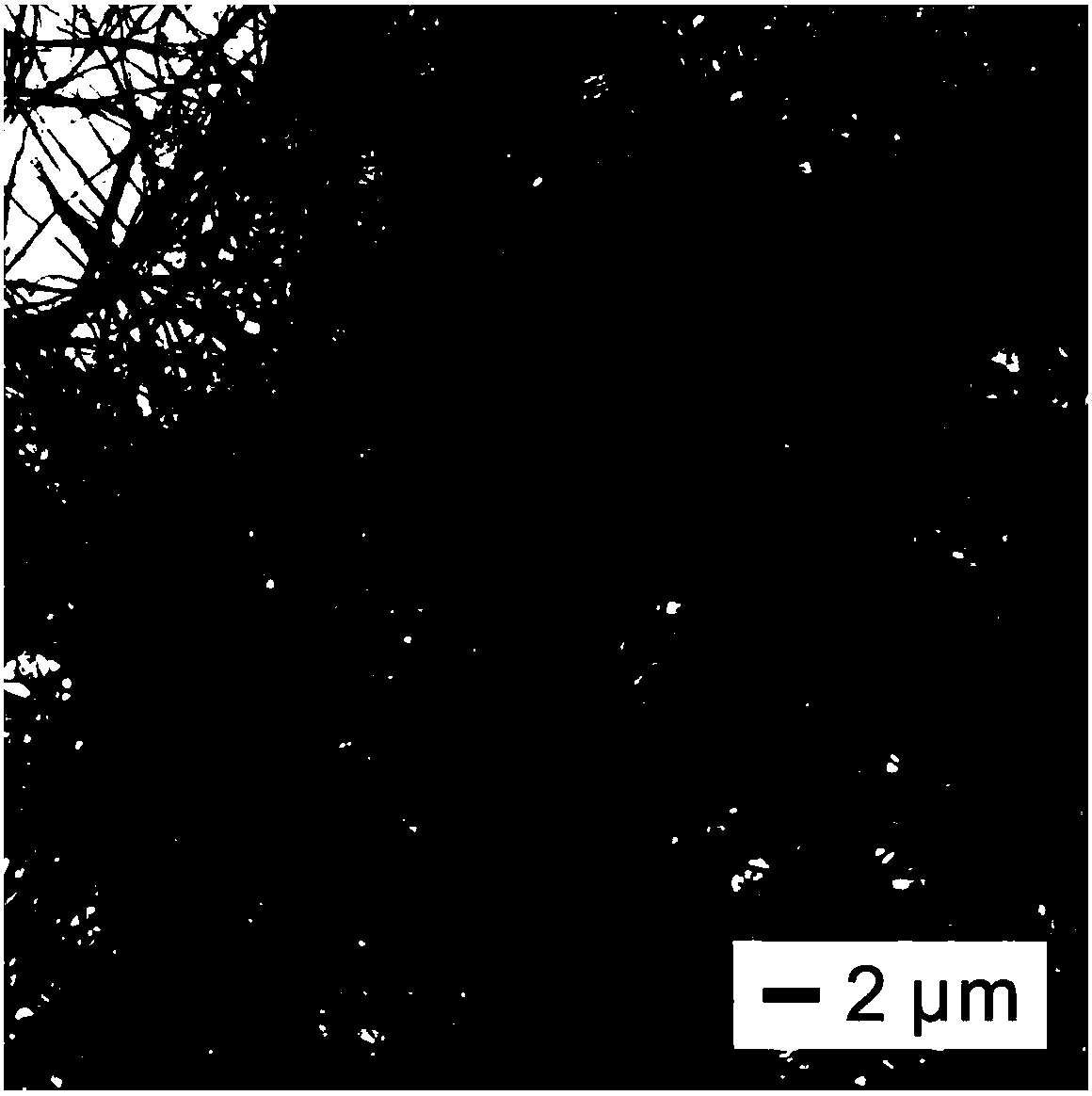

[0065] (2) Stir the solution in step (1) in an oil bath at 170°C, centrifuge after reacting for 3 minutes, discard the supernatant, and wash the bottom precipitate to obtain gold nanowires with a variety of close-packed structures mixed in random arrangements . Its transmission electron microscope pictures are shown in figure 2 middle.

Embodiment 3

[0067] (1) Set 1.25*10 -2 mmol tetrachloroauric acid and 5*10 -2 Add mmol copper chloride to 6mL oleylamine, stir and mix well.

[0068] (2) Stir the solution in step (1) in an oil bath at 160°C, centrifuge after reacting for 4 minutes, discard the supernatant, and wash the bottom precipitate to obtain gold nanowires with a variety of close-packed structures mixed in random arrangements . Its transmission electron microscope pictures are shown in image 3 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com