Sectionalized flexible roll convexity regulation and control roller

A technology of flexible rolls and rolls, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of difficult grinding of rolls, unmeasurable, and limited amount of roll crown adjustment, so as to solve the problems of roll wear and improve the strength of the rolls. The effect of shape control ability and roll stiffness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

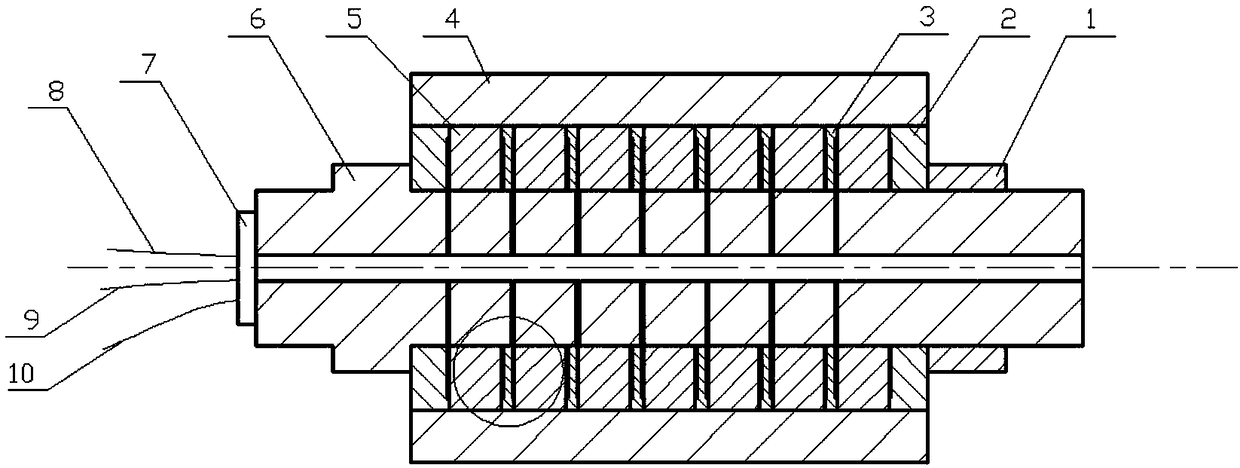

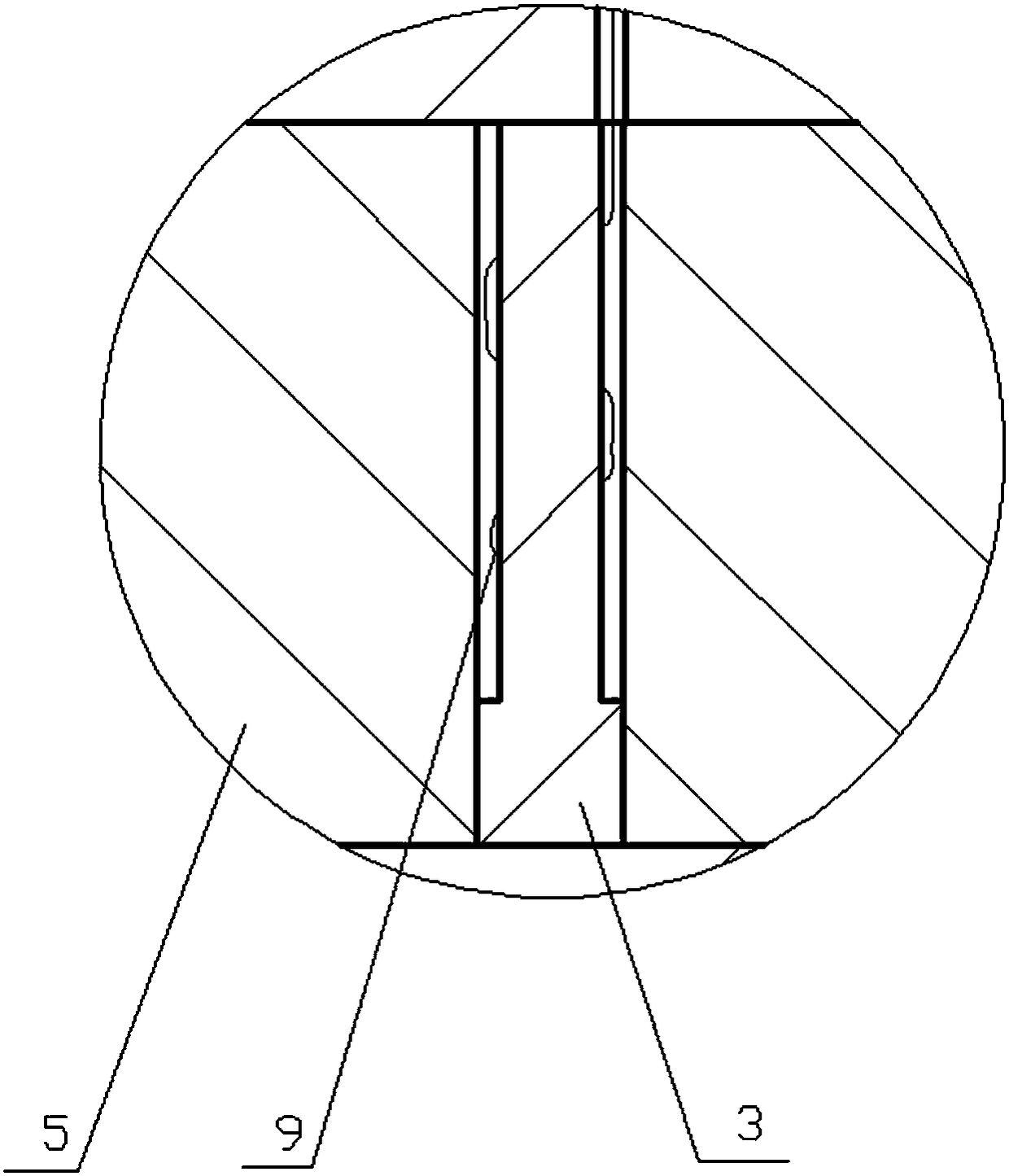

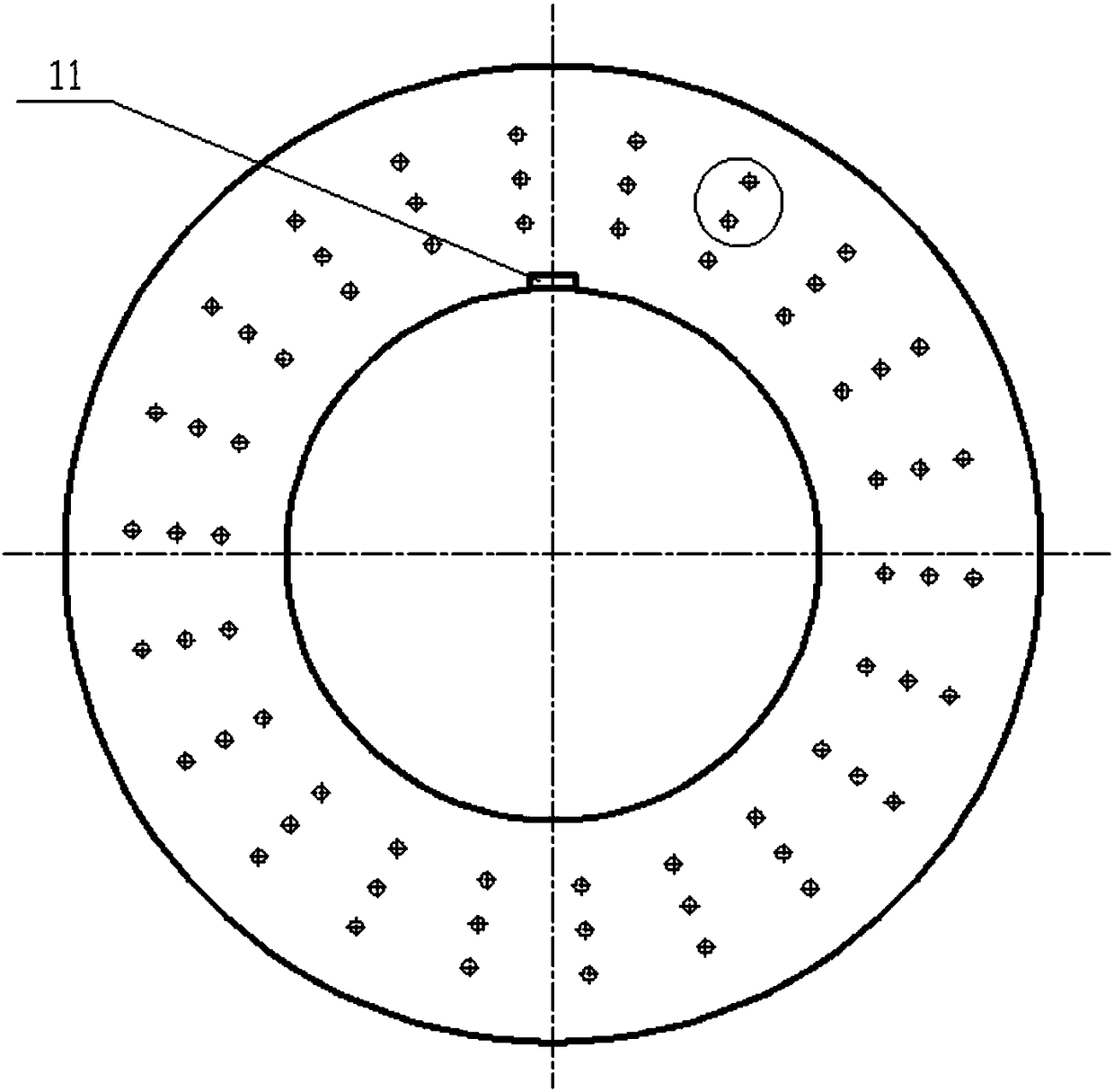

[0024] exist figure 1 In the schematic diagram of the front section of the segmented flexible roll crown control roll shown in the figure, the roll core 6 is a cylindrical forged steel metal rod with an axial center through hole inside the roll core and an annular boss on the outer side of the roll core. , the other side is provided with an external thread, and there are 7 parallel annular electromagnetic rods 5 on the non-bossed platform of the roller core. Regularly arranged axial through holes, such as image 3 As shown, there is a bundle of wires passing through these "honeycomb"-shaped vias, such as Figure 4 As shown, the winding method starts from the radially innermost circle to the outermost circle, and then winds circle by circle, and finally winds from the innermost circle again, passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com