Universal multifunctional drilling machine operating table

A console and multi-functional technology, applied in drilling equipment, earthwork drilling, drilling automatic control system, etc., can solve the problems of messy layout and many consoles, and achieve messy wiring, reduce equipment cost, increase disassembly and assembly efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

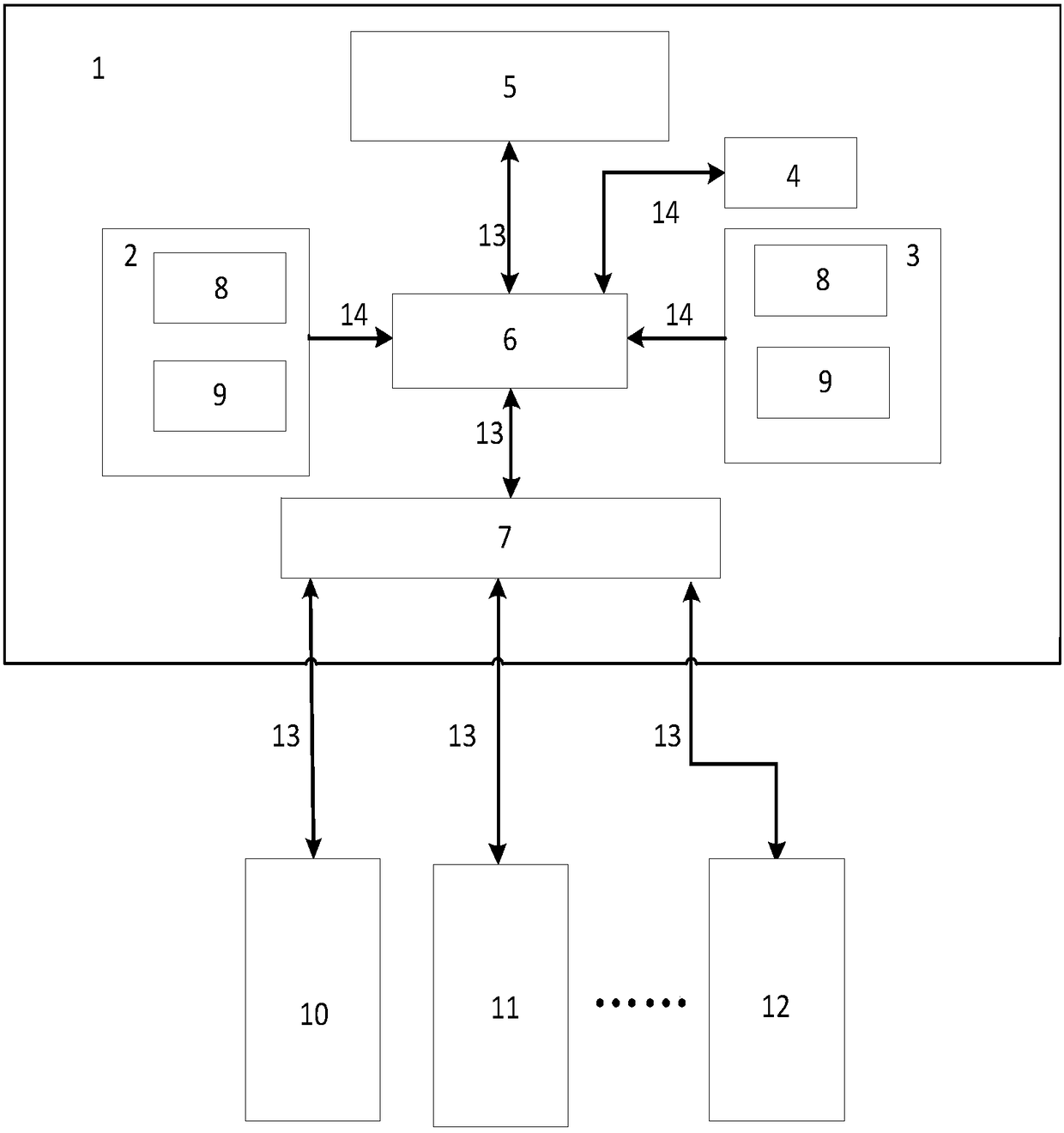

[0016] The structure of the general multi-functional drilling rig console of the present invention is as follows: figure 1 As shown, the console body 1 is included, and the console body 1 is provided with an all-in-one machine-touch screen 5. The all-in-one machine-touch screen 5 is bidirectionally connected to the console controller 6 through an industrial Ethernet cable 13, and the console controller 6 is connected to the console controller 6 through an integrated control cable 14. One-way connection to the operation area, the operation area includes a multi-function handle 8 and a multi-function keyboard 9 that are independent of each other, the console controller 6 is also bidirectionally connected to the console switch 7 through an industrial Ethernet cable 13, and the console switch 7 transmits commands to the corresponding drilling rig ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com